Cerium oxide catalyst for catalyzing and purifying nitric oxides, preparation method and application

A technology of cerium-based oxides and catalysts, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of light rare earth element backlog and achieve good resistance The effects of water resistance to sulfur and thermal stability, excellent catalytic performance, and wide operating temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

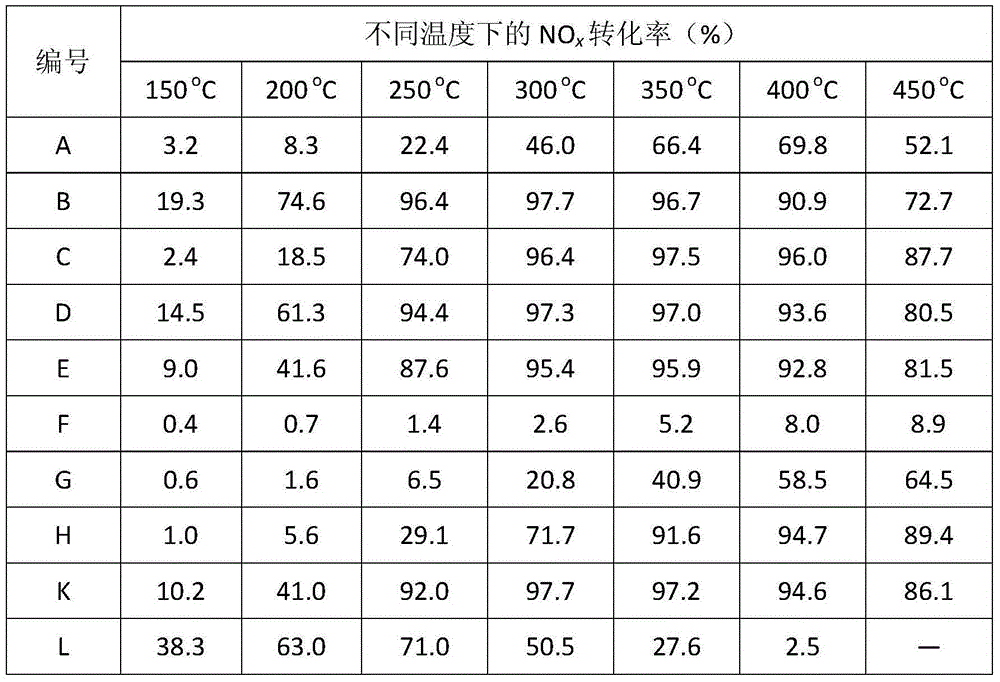

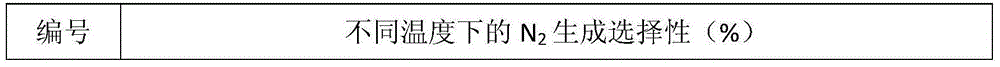

[0038] According to the Ce:Zr molar ratio of 2:1, prepare a mixed solution of cerium nitrate and zirconium nitrate, then add urea, control the pH value of the mixed solution after all the dissolution is 1.5, then heat to 80-90°C and continue stirring for 12h, the pH rises As high as 7.5, then filtered and washed, put the obtained solid in an oven and dry at 100-110°C for 12 hours, and finally roasted in air at 500°C in a muffle furnace for 5 hours to obtain a powder catalyst, called catalyst A.

Embodiment 2

[0040] According to the molar ratio of cerium, zirconium and titanium being 2:1:4, dissolve titanium sulfate in deionized water, then add cerium nitrate and zirconium nitrate, and add urea as a precipitating agent, and control the pH value of the mixed solution after all dissolution is 1.0, then heated to 80-90°C and continuously stirred for 12 hours, the pH increased to 7.0, then filtered and washed, the resulting solids were dried in an oven at 100-110°C for 12 hours, and finally passed through a muffle furnace at 500 °C in air for 5 h to obtain a powder catalyst, called catalyst B.

Embodiment 3

[0042] Other conditions were unchanged as in Example 2, and the molar ratio of cerium, zirconium, and titanium was changed to 2:1:2 to obtain catalyst C.

[0043] Example 3

[0044] Other conditions were unchanged as in Example 2, and the molar ratio of cerium, zirconium, and titanium was changed to 2:1:10 to obtain catalyst D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com