Omnidirectional luminescence flexible LED filament and manufacturing method thereof

An LED filament and full-angle light-emitting technology, which is applied in the field of LED lighting, can solve the problems of fragile materials, blue leakage on the side of the substrate, and high price, and achieve the effects of overcoming heat yellowing, overcoming light distribution design, and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

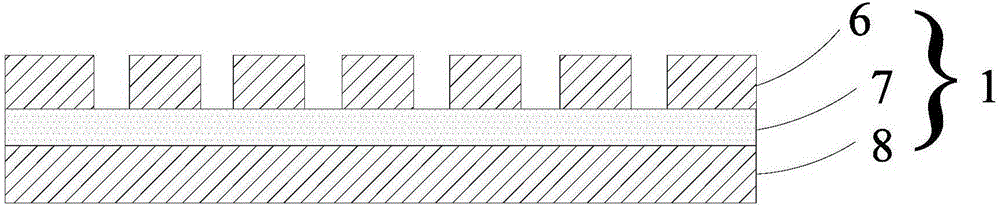

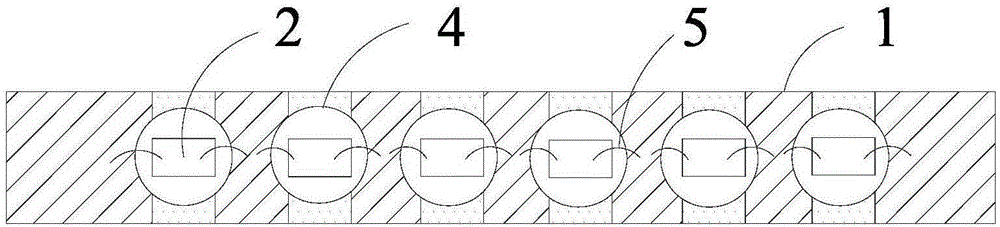

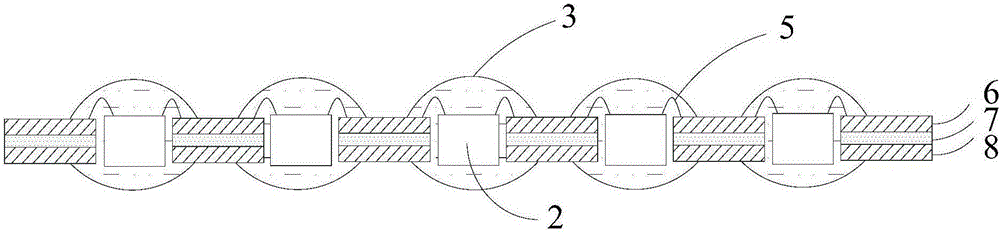

[0044] In this example, please refer to Figure 1 to Figure 4 , a flexible LED filament that emits light at all angles is proposed, which includes a flexible substrate 1 , an LED light emitting module 2 and a fluorescent encapsulation layer 3 . The flexible substrate 1 is formed by laminating three layers of materials: the first copper foil layer 6, the polyimide base layer 7 and the second copper foil layer 8, and a circuit layer is formed on the first copper foil layer and formed on both sides of the substrate respectively. The positive electrode and the negative electrode are connected to the driving power supply, and the second copper foil layer 8 is mainly used for heat dissipation of the LED chip, thereby improving the heat dissipation capacity of the LED filament and prolonging the service life.

[0045] The LED light-emitting module includes one or more LED chip groups connected in parallel. The LED chip group is composed of multiple LED chips connected in series. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com