Forming technology and production device for circulating water fish farming water tank

A technology for production equipment and running water fish, which is applied to household components, household appliances, and other household appliances. It can solve problems such as difficult construction, long construction period, and inability to transport, so as to overcome untimely heat dissipation and accelerate wear and avoid stress concentration. Effect of cracking and ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

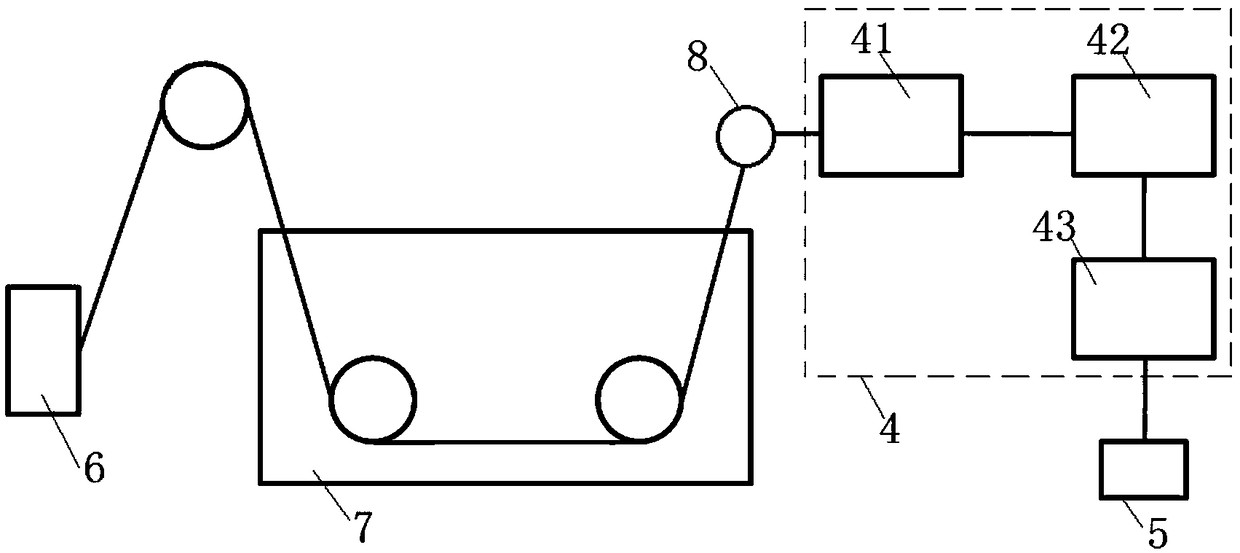

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

[0035]A forming process of a circulating water fish breeding tank: the assembly parts of the breeding tank are made through a pultrusion process, and the forming process mainly includes the following steps;

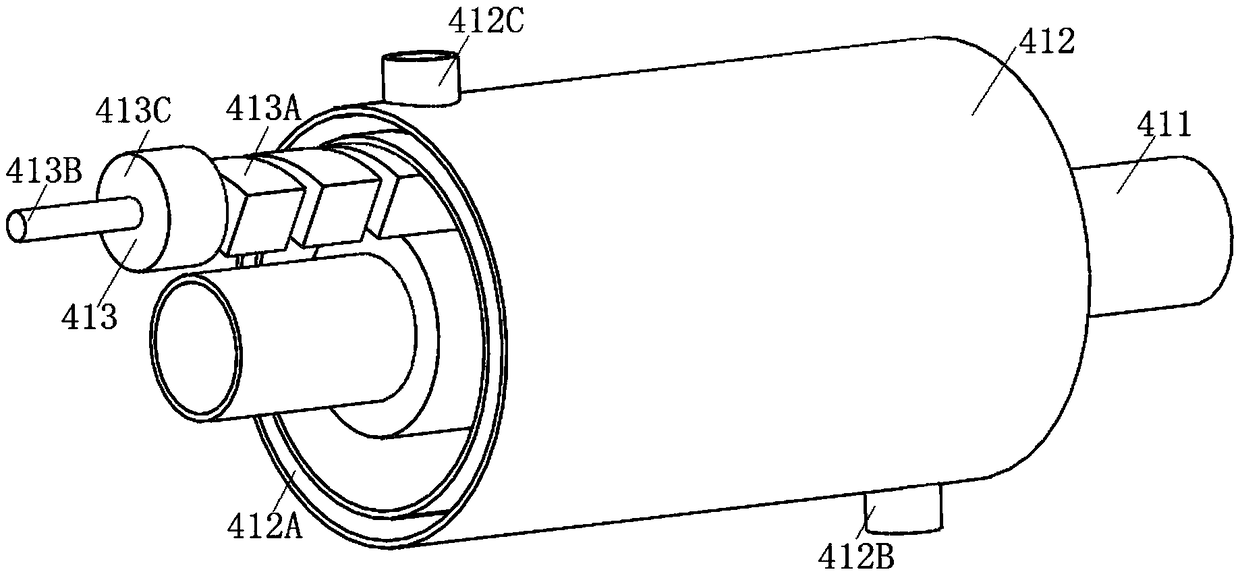

[0036] Step 1, the hot water supplier works, and the constant temperature circulating hot water is input to the heating chamber 412A, and the temperature of the hot water is T1;

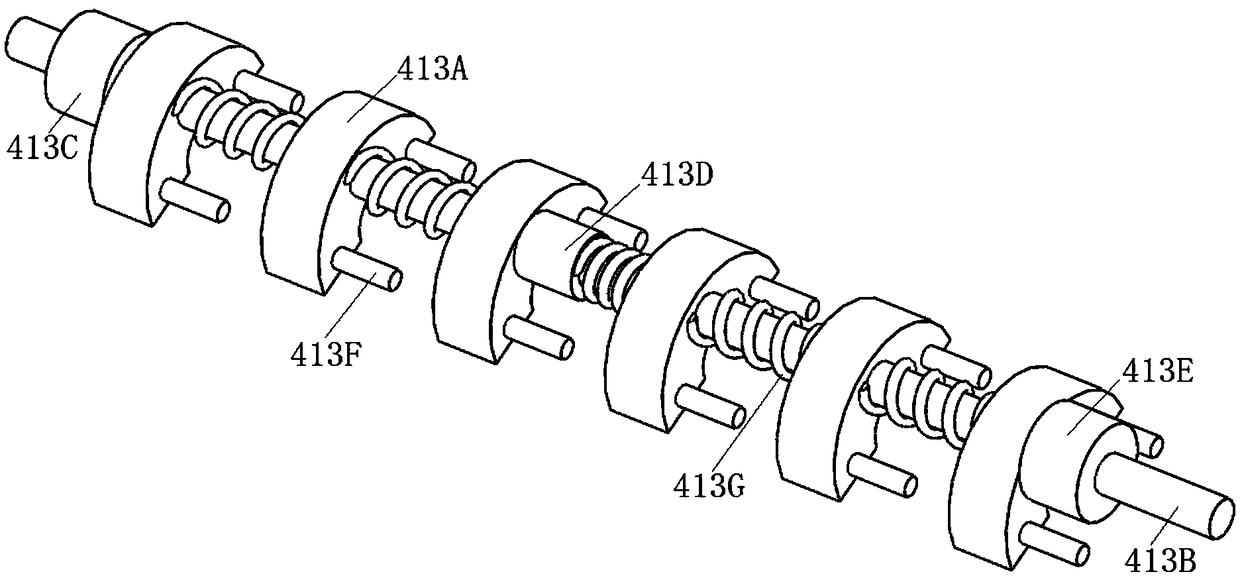

[0037] Step 2, the fiber bundle wrapped with liquid resin enters the conveying pipe 411 of the thermostat 41, and the heat spreader 413 conducts the temperature of the heating chamber 412A to the conveying pipe 411, thereby heating the resin to reduce its fluidity, for subsequent prepare for solidification;

[0038] Wherein, the arrangement density of the heat conduction blocks 413A on both sides of the third fixed section 413E can be adjusted independently; the first heating section is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com