Integrated animal oil extraction and treatment system

A technology of animal fat and processing system, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of easy broken shaft, poor adaptability, accumulation of oil residue, etc., to ensure no burning of the pot and oil quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

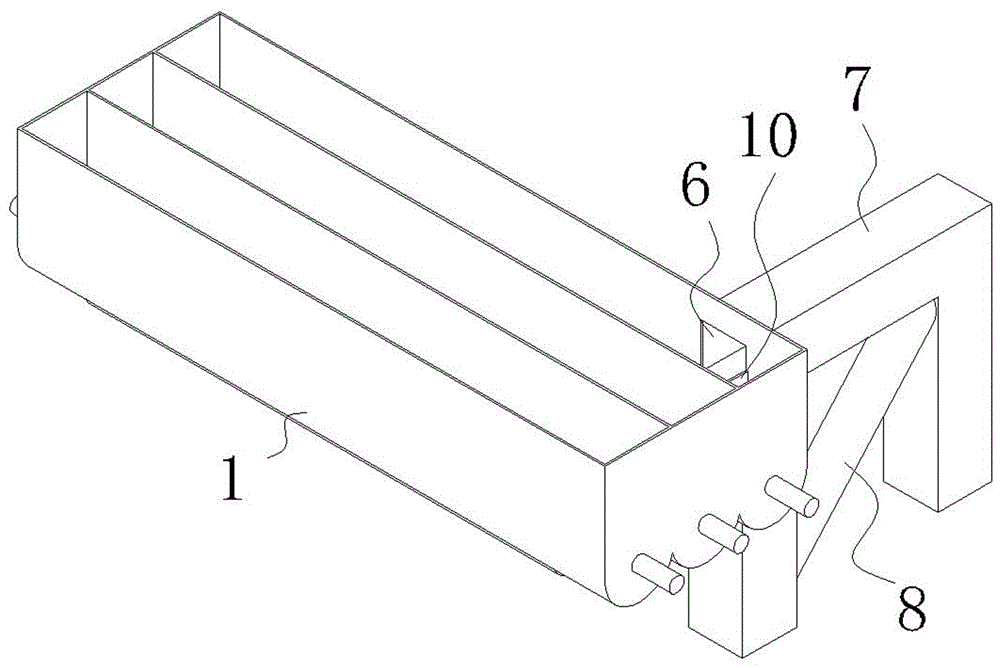

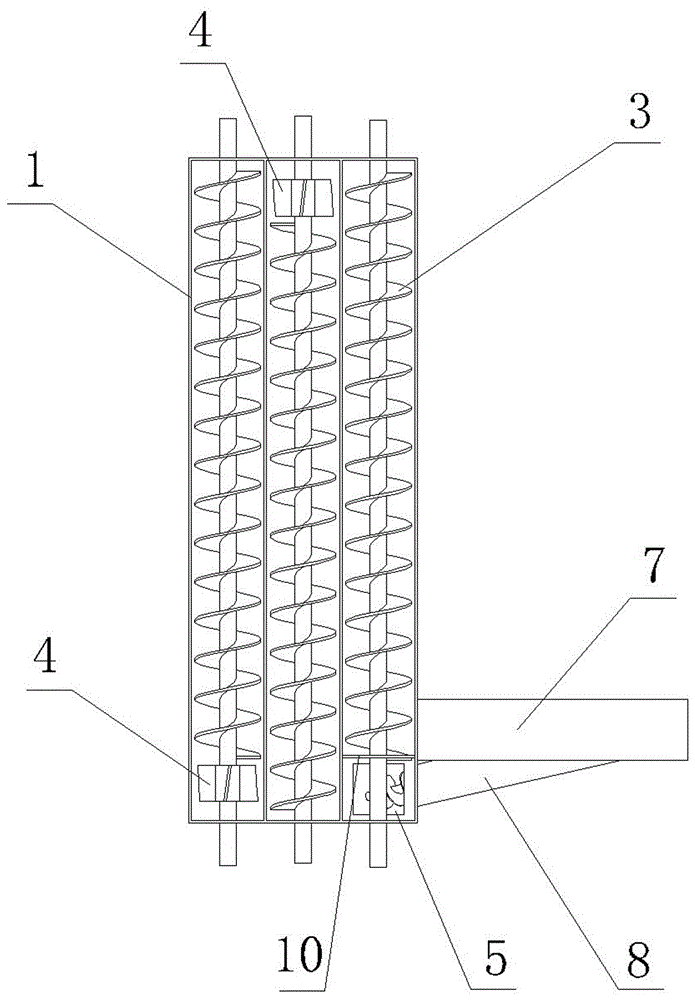

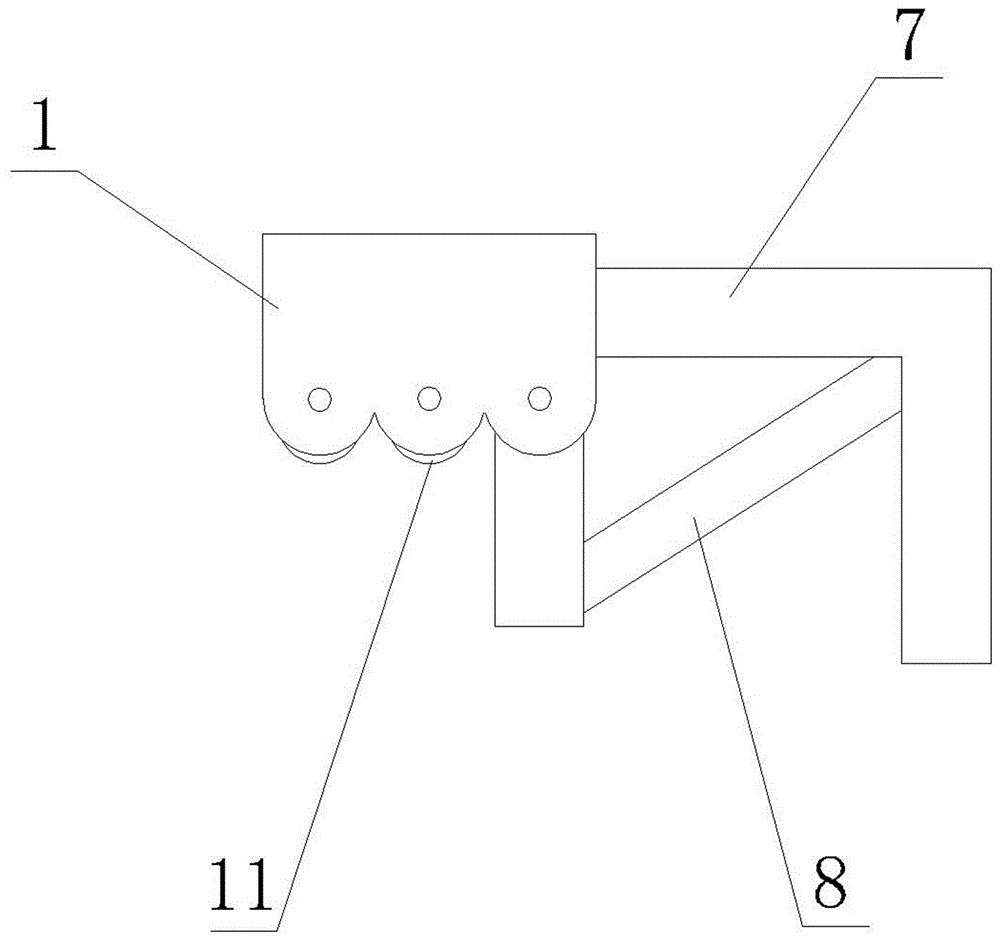

[0035] Such as Figure 1~7 As shown, an integrated animal fat extraction and treatment system includes a feeding part, a driving part, a refining part, a heating part and an oil residue separation system, wherein the refining part is formed by three U-shaped tanks 1 arranged side by side , two adjacent U-shaped grooves share one wallboard, and each shared wallboard is provided with a via hole 2, which is located at one end of the U-shaped groove 1, and the viaholes 2 of the adjacent two wallboards are respectively arranged on Different ends of the U-shaped slots, each of the U-shaped slots 1 is provided with an auger 3, and the driving part is connected to and drives the auger 3 to rotate, so that the objects in the adjacent U-shaped slots 2 are facing toward each other. Movement in the opposite direction, except for the U-shaped groove 1 at the end, the end of the auger 3 in the other U-shaped groove 1 is provided with a transfer device 4, corresponding to the through hole 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com