Check valve for chemical fiber spinning device

A shut-off valve and equipment technology, applied in mechanical equipment, lifting valves, valve details, etc., can solve the problems of easy retreat, melt leakage, high cost, etc., and achieve the effect of self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

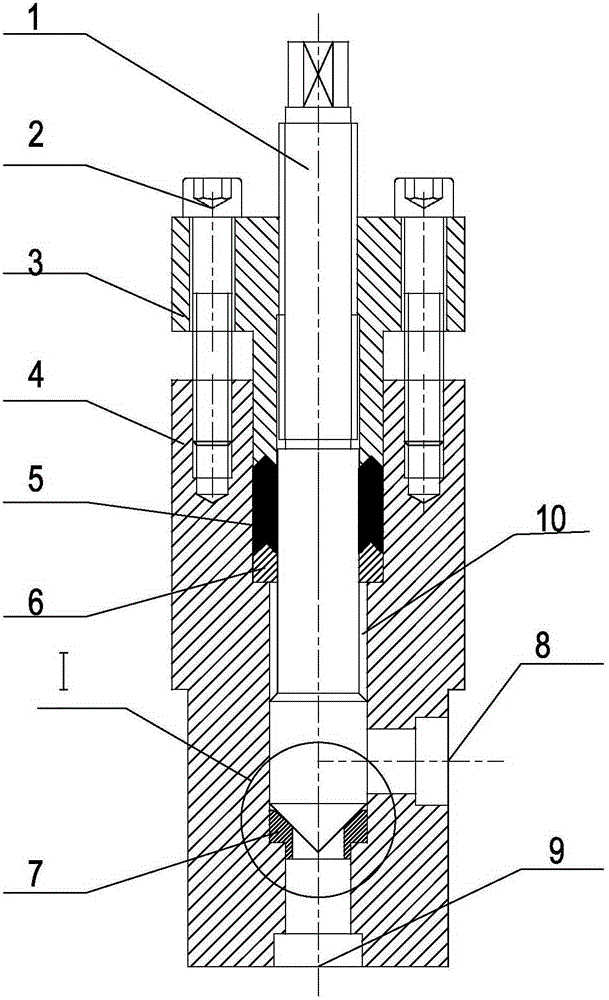

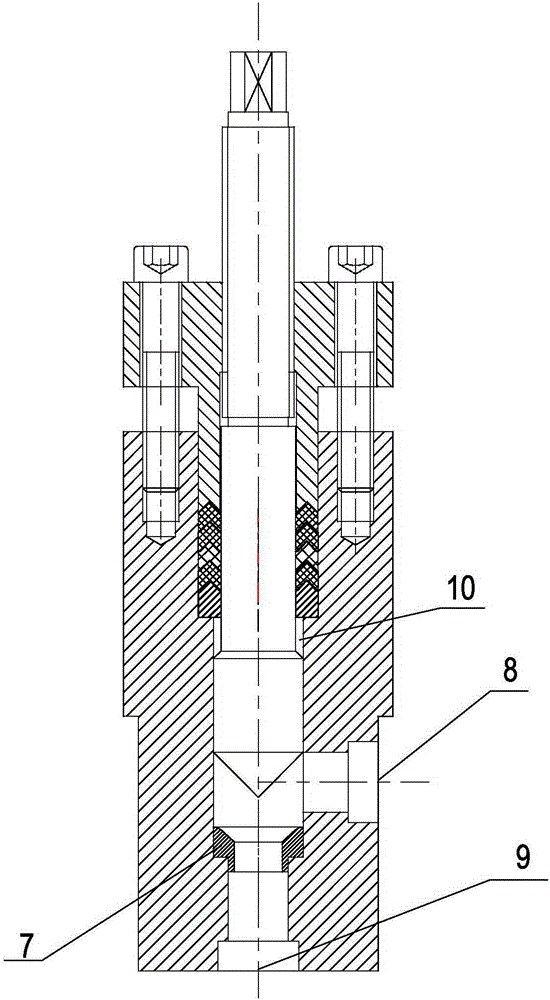

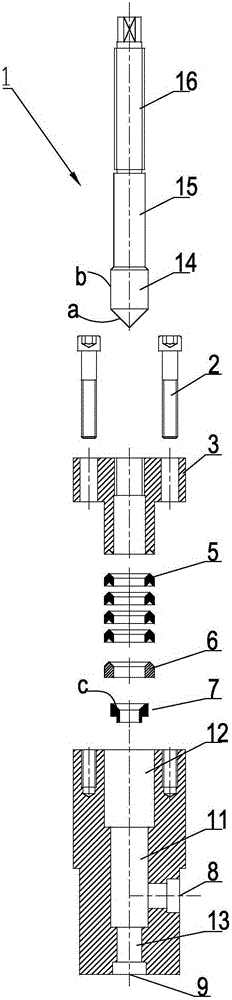

[0020] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings. figure 1 The upper and lower positional relationship in .

[0021] See attached Figure 1~4 As shown, this embodiment discloses a shut-off valve for chemical fiber spinning equipment, which is arranged on the melt channel of the chemical fiber spinning equipment. The shut-off valve includes a valve body 4, a valve cover 3, a valve stem 1, fastening screws 2, and a valve core 7. The valve body 4 is provided with a valve cavity that penetrates up and down. The valve cavity includes the second center hole 12, the first center hole 11, the third center hole 13 and the melt outlet 9 arranged in sequence from top to bottom, and the second center The inner diameter of the hole 12 is larger than the inner diameter of the first central hole 11 , and the inner diameter of the first central hole 11 is larger than the inner diameter of the third central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com