Method for preparing porous titanium powder

A technology for porous titanium and titanium raw materials, which is applied in the field of preparing porous titanium powder, can solve problems such as difficult to stabilize porous titanium powder, and achieve the effect of improving the average valence state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

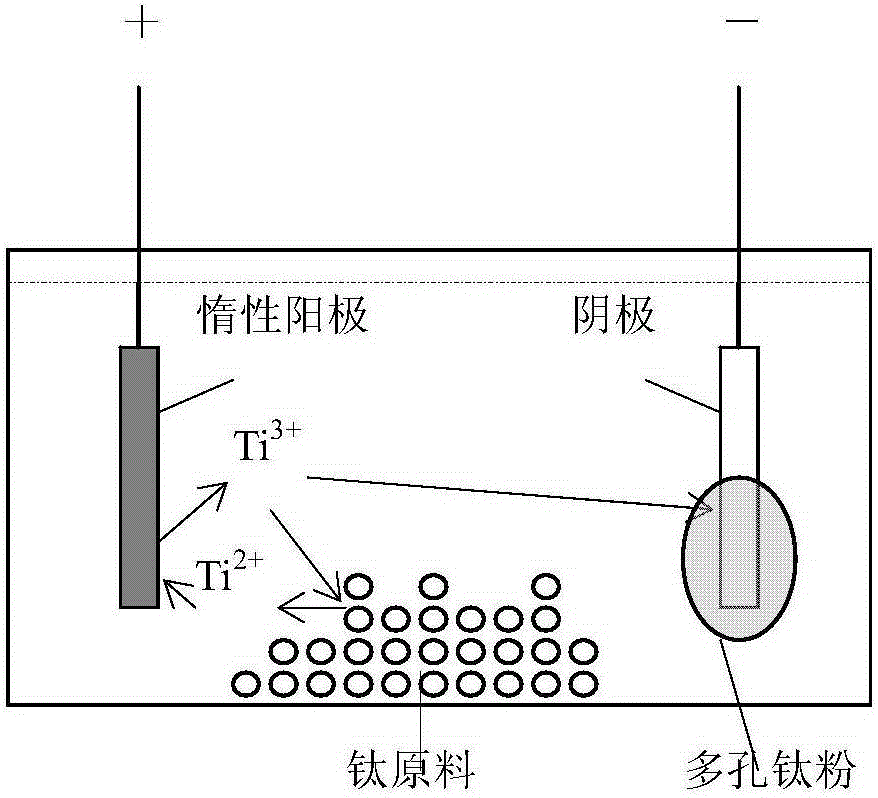

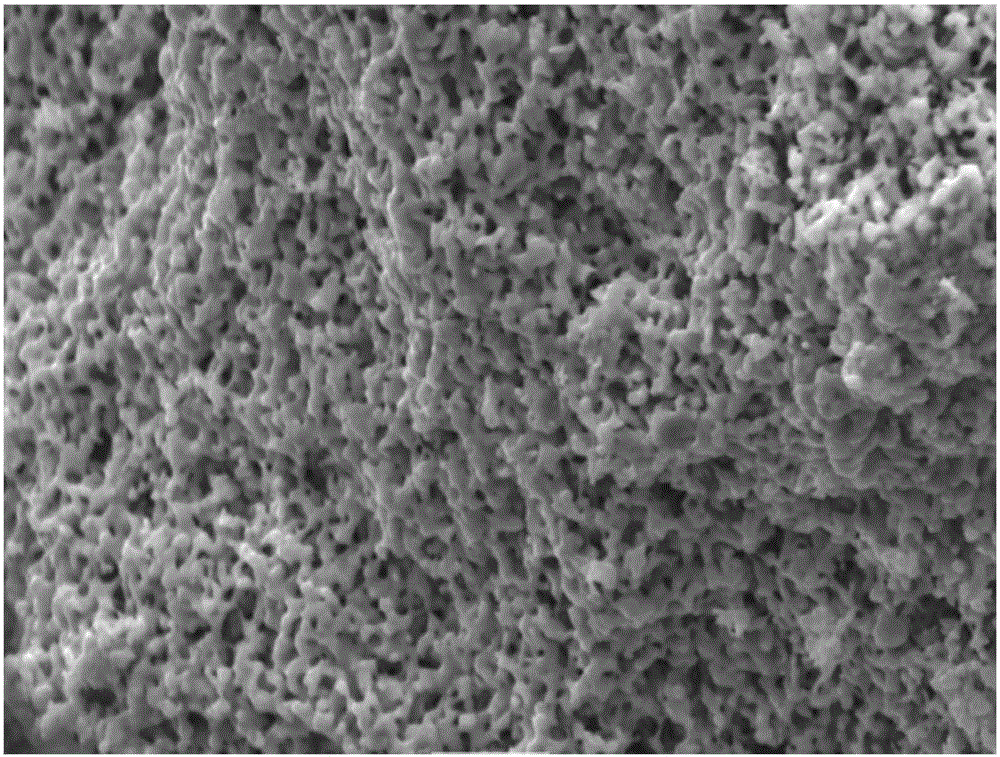

[0052] With graphite as anode and carbon steel as cathode, 10wt% TiCl is added to NaCl and KCl in equimolar ratio 3 The mixture formed is an electrolyte to form an electrolytic cell, and titanium sponge is added into the electrolyte as a raw material, and a direct current is connected for electrolysis. The total concentration of titanium ions in the electrolyte is 1.0wt%, and the anode current density is controlled to 0.8A / cm 2 , cathode current density 0.1A / cm 2 , the electrolysis temperature is 760°C. After the electrolysis, the product obtained from the cathode is washed with dilute hydrochloric acid and then observed by SEM. The results are as follows figure 2 As shown, the porous morphology of the obtained titanium powder is uniform.

Embodiment 2

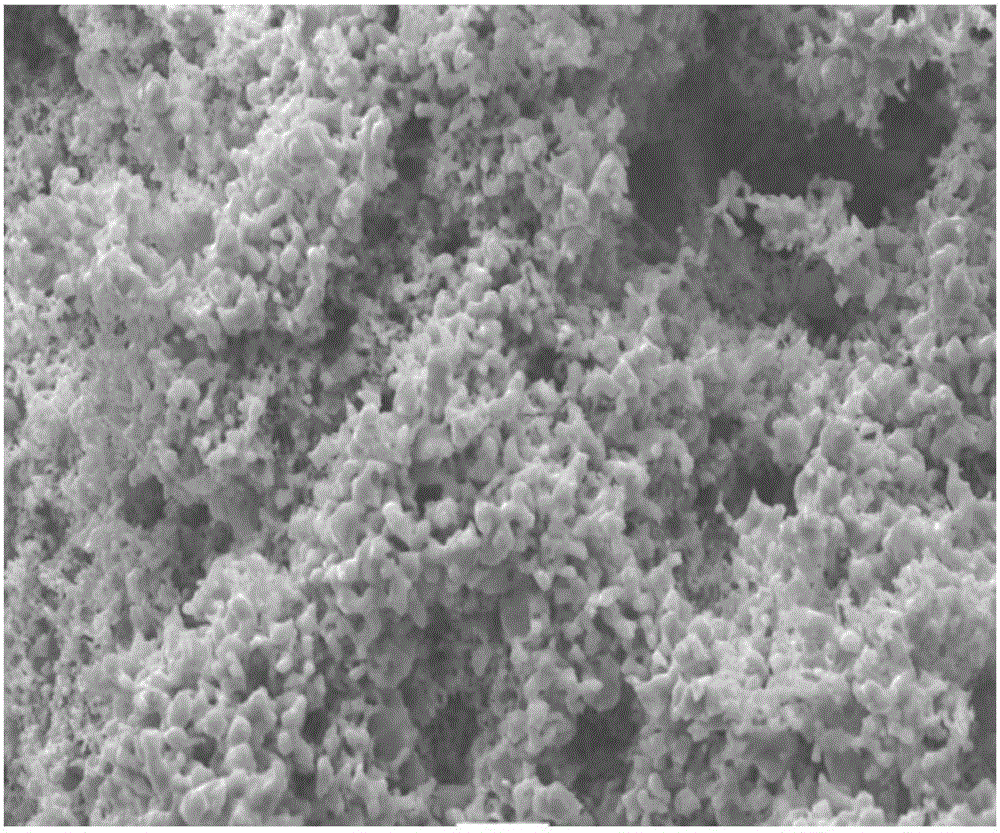

[0054] With graphite as anode and carbon steel as cathode, 15wt% TiCl is added to NaCl and KCl in equimolar ratio 2 The mixture formed is an electrolyte to form an electrolytic cell, and titanium sponge is added into the electrolyte as a raw material, and a direct current is connected for electrolysis. Control the anode current density 0.2A / cm 2 , cathode current density 0.8A / cm 2 , the electrolysis temperature is 850°C. After the electrolysis, the product obtained from the cathode is washed with dilute hydrochloric acid and then observed by SEM. The results are as follows image 3 As shown, the obtained titanium powder has a uniform porous morphology, and the difference from the product obtained in Example 1 is that the basic particle diameter is relatively coarse.

Embodiment 3

[0056] With graphite as anode and carbon steel as cathode, 8wt% TiCl is added to NaCl and KCl in equimolar ratio 2 , 9wt% TiCl 3 The formed mixture is used as an electrolyte to form an electrolytic cell, and titanium sponge is added into the electrolyte as a raw material, and a direct current is connected for electrolysis. Control the anode current density 0.5A / cm 2 , cathode current density 0.3A / cm 2 , the electrolysis temperature is 800°C. After the electrolysis, the product obtained from the cathode is washed with dilute hydrochloric acid and then observed by SEM. The results are as follows Figure 4 As shown, the obtained titanium powder has a uniform porous morphology, and the basic particle diameter of the obtained product is between that of Example 1 and Example 2.

[0057] Although the invention has been described above in conjunction with exemplary embodiments, it will be apparent to those skilled in the art that various modifications may be made to the above embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com