A kind of preparation method of laminated lithium nickel manganese oxide

A technology of lithium nickel manganate and manganese salt is applied in the field of preparation of layered positive electrode materials, which can solve the problems of high process cost, high risk and difficulty, and achieve the advantages of easy popularization and implementation, cheap raw materials, and avoiding the existence of low-priced manganese. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The present invention is a kind of preparation method of laminated lithium nickel manganese oxide material, and its steps are:

[0015] (1) At room temperature, dissolve the manganese salt in a mixture of alcohol and water at a ratio of 1:9-1:1. The molar concentration of manganese ions in the aqueous alcohol solution is 0.3-1.5 mol / L. In the above mixed solution Lithium salt is directly added to the solution; the amount of manganese and lithium salt is determined at a molar ratio of 3:2; then, under stirring conditions, hydrogen peroxide whose molar number is 0.4-2 times the molar number of manganese salt is added to the above solution, and a black solution is obtained at this time. ;

[0016] (2) Add nickel salt to the above black solution, the amount of manganese, lithium and nickel salt should be determined according to the molar ratio of 3:2:1, and continue to stir for 1-6 h;

[0017] (3) Heating the obtained solution at 70-100°C to recover the solvent and obtain ...

Embodiment 1

[0024] (1) Dissolve 0.3 mol of manganese sulfate and 0.2 mol of lithium sulfate in a mixture of 1 L of ethanol and water (volume ratio of alcohol to water is 3:9);

[0025] (2) Add 0.12 mol (24 wt%) hydrogen peroxide, then add 0.1 mol nickel acetate, and keep stirring for 3 h;

[0026] (3) The obtained solution is heated at 90°C to recover the solvent and obtain a jelly. Then the jelly was dried in an oven at 120 °C for 8 h;

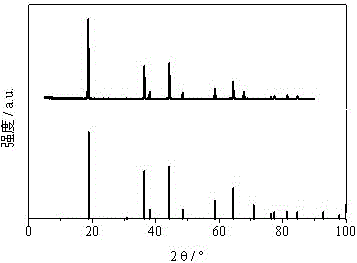

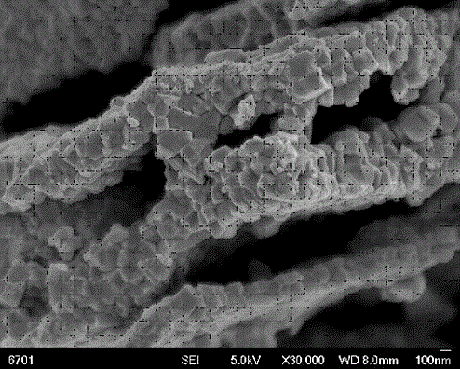

[0027] (4) Finally, the dried material was calcined in a muffle furnace at 800 °C for 8 h to obtain the following figure 1 , 2 The laminates shown are lithium nickel manganese oxide materials.

Embodiment 2

[0029] (1) Dissolve 0.9 mol of manganese acetate and 0.6 mol of lithium acetate in a mixture of 1 L of ethanol and water (volume ratio of alcohol to water is 1:9);

[0030] (2) Add 0.45 mol (24 wt%) hydrogen peroxide, then add 0.3 mol nickel acetate, and keep stirring for 3 h;

[0031] (3) The obtained solution was heated at 100°C to recover the solvent and obtain a jelly. Then the jelly was dried in an oven at 120 °C for 8 h;

[0032] (4) Finally, the dried material was calcined in a muffle furnace at 850 °C for 9 h to obtain a laminated lithium nickel manganese oxide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com