Plant sterilization and parasite expelling function type water-borne wood paint and preparation method thereof

A water-based wood paint and plant sterilization technology, which is applied to biocide-containing paints, antifouling/underwater paints, coatings, etc., can solve the problem of unspecified wood paint components, aloe vera oil, and mugwort oil that are volatile and have no sterilization Antibacterial performance and other issues, to achieve the effect of excellent surface enrichment, low price, easy access and purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

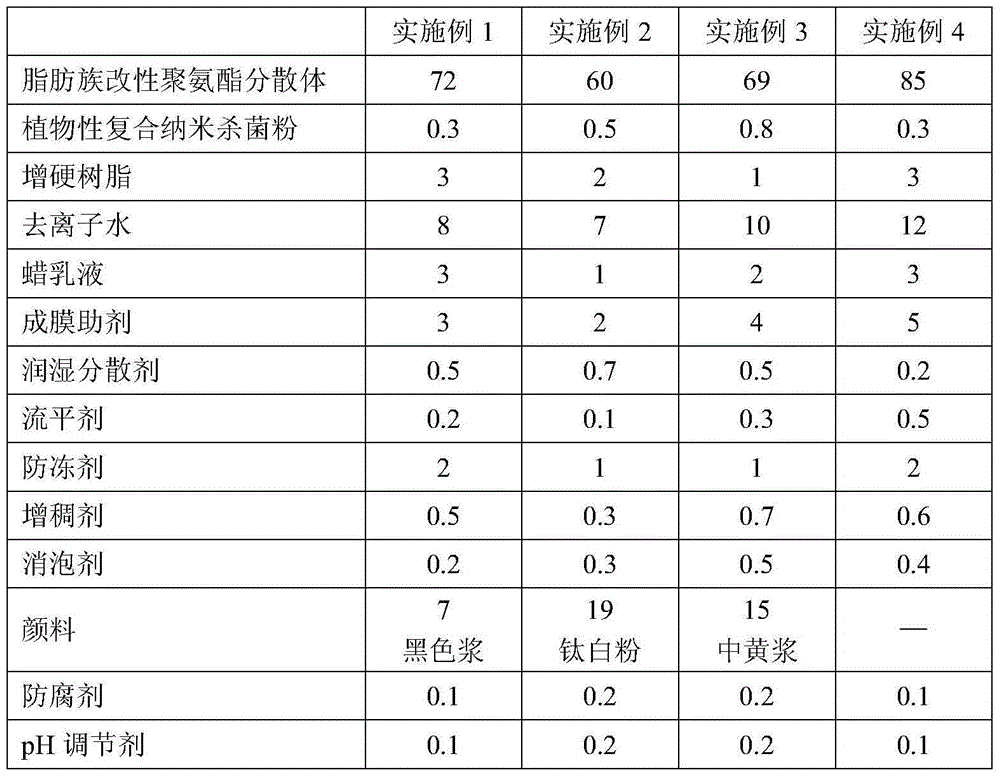

[0057] Wash and slice the fresh leaves, branches and roots of camphor trees, cedar, pine needles, arborvitae and purslane, and conduct infrared radiation heating for rapid dehydration and drying. Carry out nano-grinding production technology for grinding and crushing to obtain nano camphor tree powder, nano cedar powder, nano pine needle powder, nano arborvitae powder, and nano purslane powder with nano-scale particle size. These nanoscale plant bactericidal powders are then mixed in proportions by weight shown in Table 1 to make corresponding plant-based composite nano bactericidal powders. The particle size of the nanopowder is also shown in Table 1.

[0058] Table 1 Formula and particle size of plant-based composite nano-bactericidal powder

[0059]

Example 1

Example 2

Example 3

Example 4

Nano purslane powder

3

4

1

5

Nano camphor tree powder

2

3

3

1

Nano cedar powder

2

—

3

1

...

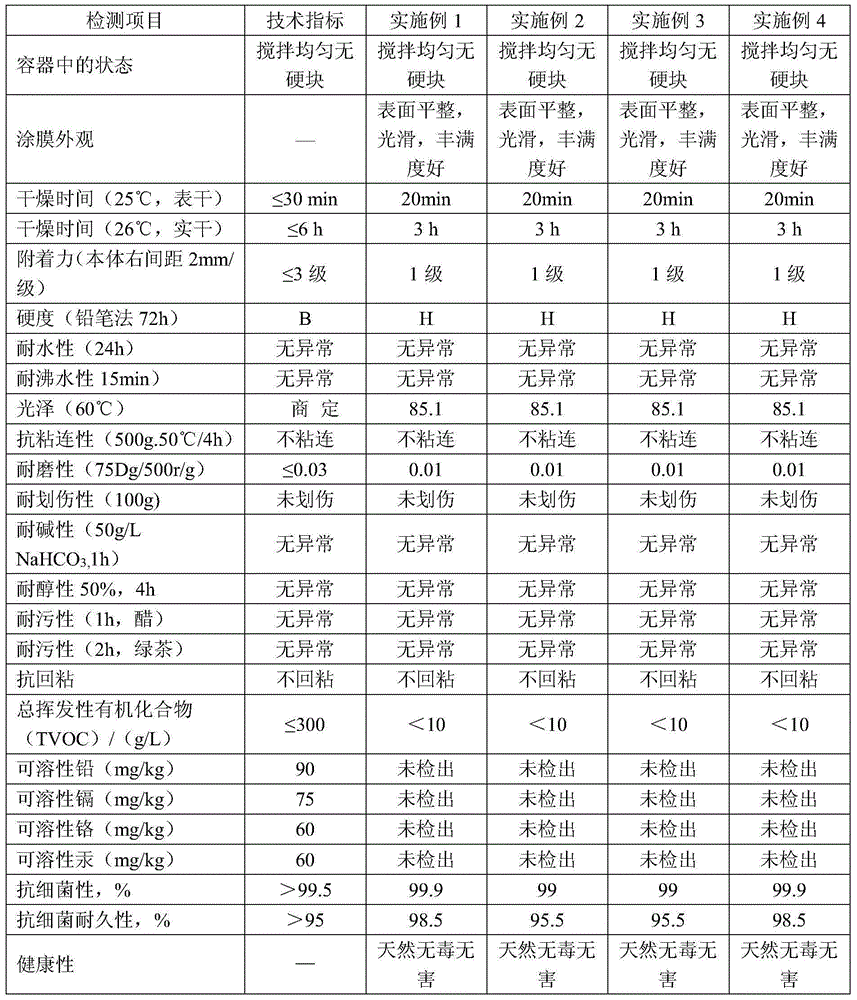

Embodiment 1

[0067] Prepare plant bactericidal insect repellent functional type water-based black wood topcoat by the formula weight part of table 4, comprise the following steps:

[0068]a) Prepare raw materials according to the weight parts set by the formula, put water, wetting and dispersing agent, black pulp, and defoamer into the container and stir at a high speed of 1300-1400 rpm, stir for 15 minutes, and then reduce the speed to 1000 rpm, Add aliphatic modified polyurethane dispersion and hardening resin while stirring. After stirring for 10 minutes, add antifreeze, wax emulsion, and plant-based composite nano-bactericidal powder and stir for 5 minutes. The speed is reduced to 600 rpm, and the pH regulator is added. Adjust the pH value to 8, add a thickener to adjust the viscosity required by the customer.

[0069] b) Test-filter-package-sample retention.

Embodiment 2

[0071] The adjustment of the formula ratio of this embodiment is shown in Table 4. The specific implementation process is basically the same as that of Example 1, the only difference being that the high-speed stirring speed is 1400-1500 revolutions per minute, and the stirring time is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com