Preparation method for lithium-based glass ceramic for dental prosthesis

A technology of glass ceramics and prosthetics, applied in the field of dental prosthetics, can solve problems such as reduction of Si-OH functional groups, reduction of material bioactivity, and difficult control of components, and achieve high solubility, energy saving, and precise control of components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

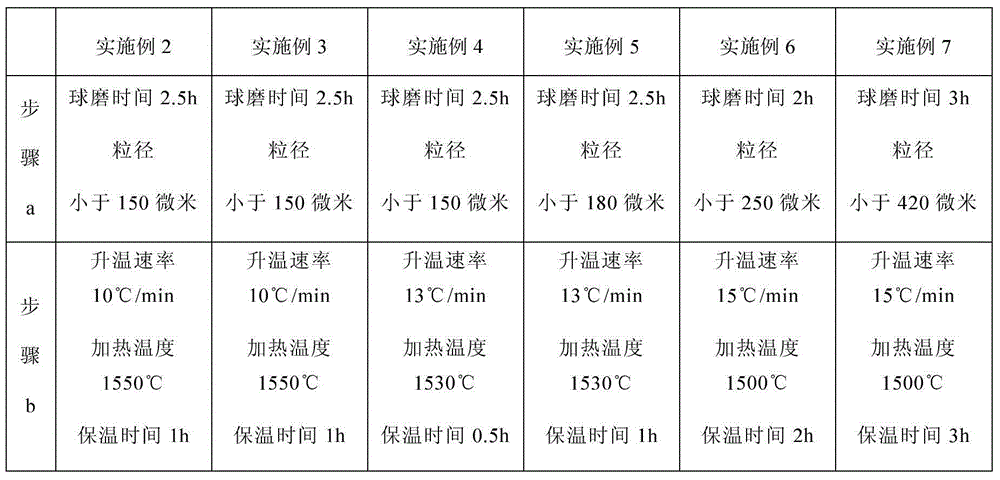

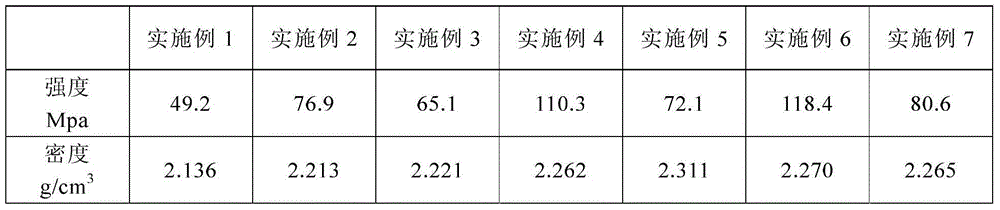

[0056] Preparation of lithium-based glass ceramics for dental restorations, the preparation method is as follows:

[0057] A, take by weighing each matrix raw material by the quality of each component of embodiment 1 in table 1, then each matrix raw material is ball-milled with ball mill for 2.5 hours respectively, obtains the batch material that particle diameter is less than 150 microns;

[0058] b. Put the prepared batch material into a platinum crucible, heat it to 1550° C. in a sintering furnace at a heating rate of 10° C. / min, and keep it warm for 1 hour to clarify and homogenize to obtain molten glass;

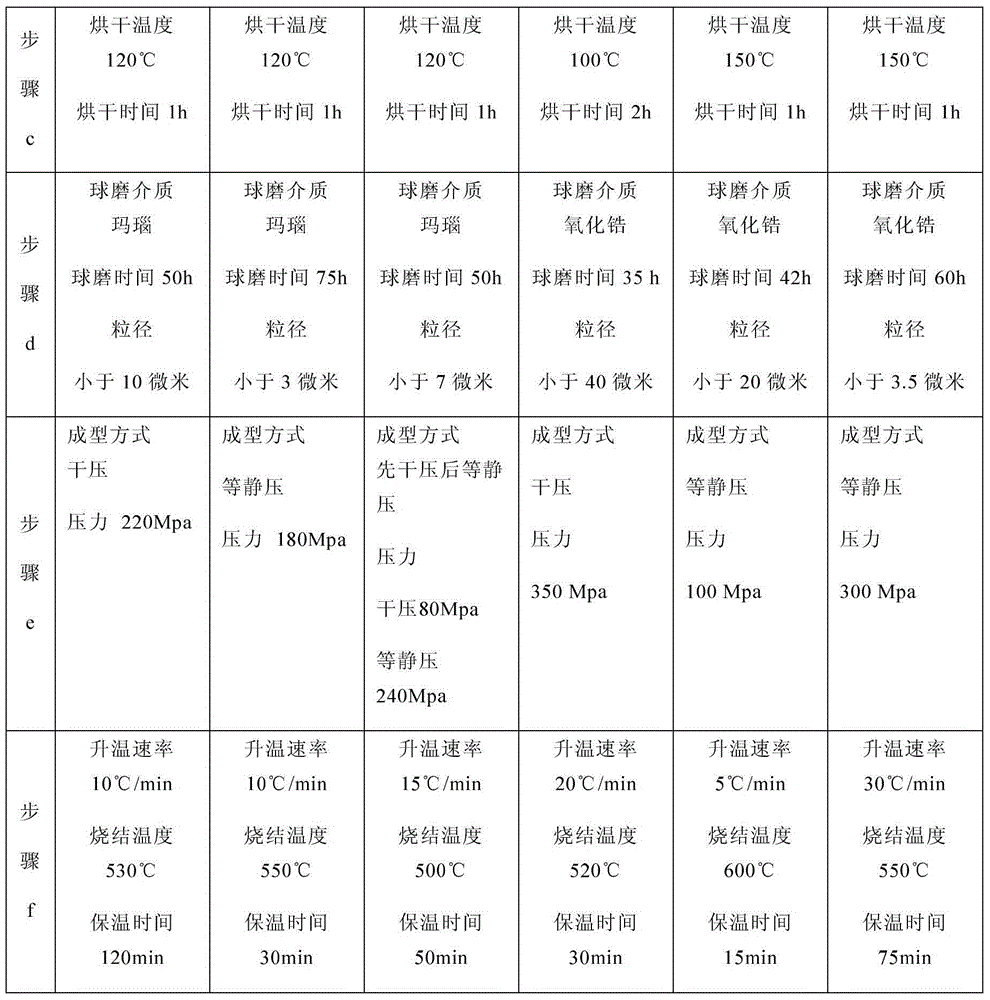

[0059] c. Water quenching the prepared molten glass to obtain glass cullets, and then drying the glass cullets at 120° C. for 1 hour;

[0060] d, the dried glass pieces are put into a ball mill jar with agate as a ball mill medium for ball milling, the amount of added agate balls is 200g, ball milled for 50 hours, to obtain a glass powder with a particle size less than 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com