A petrochemical comprehensive wastewater treatment device and petrochemical comprehensive wastewater treatment method

A technology that integrates waste water and treatment devices. It is applied in the fields of natural water treatment, chemical instruments and methods, and multi-stage water/sewage treatment. , the effect of reducing the dosage of ozone and improving the biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

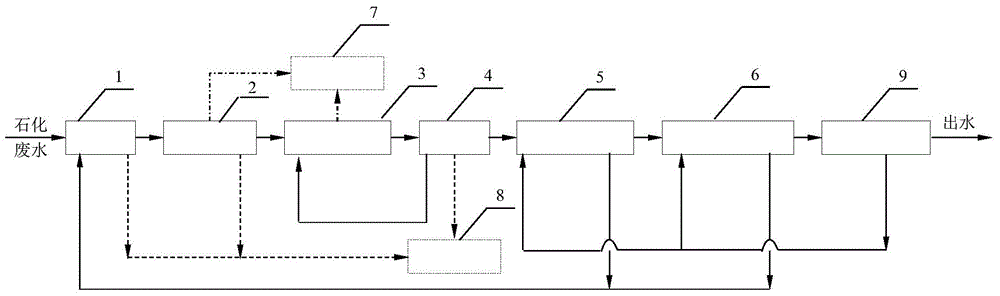

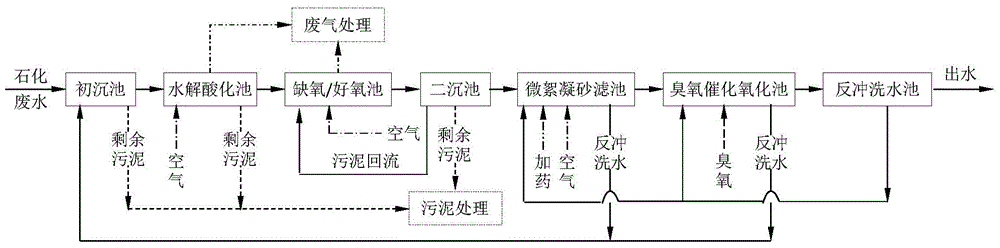

[0032] Such as figure 1 with figure 2 As shown, a petrochemical integrated wastewater treatment device includes a primary sedimentation tank 1, a hydrolysis acidification tank 2, an anoxic / aerobic tank 3, a secondary sedimentation tank 4, a micro-flocculated sand filter tank 5, and an ozone catalytic oxidation tank 6 connected in sequence And backwash basin 9. The primary sedimentation tank 1 is connected to the petrochemical wastewater input pipeline, and the catalytic oxidation tank 6 is provided with a treatment water outlet; the hydrolysis acidification tank 2 and the anoxic / aerobic tank 3 are respectively connected to the waste gas treatment device 7, the primary sedimentation tank 1, hydrolysis The acidification tank 2 and the secondary sedimentation tank 4 are respectively connected to the sludge treatment device 8, the micro-flocculated sand filter tank 5 and the catalytic oxidation tank 6 are respectively connected to the primary sedimentation tank 1 through a backwash...

Embodiment 2

[0034] The method for treating comprehensive petrochemical wastewater by adopting the comprehensive petrochemical wastewater treatment device of the present invention includes the following steps:

[0035] The comprehensive petrochemical wastewater is deposited in the primary sedimentation tank 1 to remove part of the suspended matter. The effluent from the primary sedimentation tank 1 enters the hydrolysis acidification tank 2 to remove some organic matter. The effluent from the hydrolysis acidification tank 2 enters the anoxic / aerobic tank 3 for further treatment to remove most of the Organic matter and nitrogen. After the effluent from the anoxic / aerobic tank 3 is separated from the mud and water in the secondary settling tank 4, the effluent enters the micro-flocculated sand filter tank 5 to further remove suspended solids in the wastewater, while removing part of the organic matter, nitrogen and phosphorus; The ozone catalytic oxidation pool 6 performs further catalytic oxida...

Embodiment 3

[0039] The difference from Example 2 is that the hydrolysis and acidification tank 2 is a microaerobic-anaerobic cross hydrolysis and acidification tank with a hydraulic retention time of 24h and a gas-water ratio of 0.25:1. Anoxic / aerobic tank 3 has a hydraulic retention time of 24h, aerobic tank air-water ratio of 10:1, and a sludge return ratio of 200%. Add medicament to microflocculation sand filter 5, medicament is PAFC, dosage is 15mg / L. The micro-flocculated sand filter 5 adopts an internal circulation continuous sand filter, and the filter material is quartz sand with a particle size of 0.5-1.0mm; the micro-flocculated sand filter 5 has a filtration rate of 7m / h and an air-water ratio of 0.5 :1. The ozone catalytic oxidation tank 6 has water inlet at the upper part, water outlet at the bottom, and ozone at the bottom. The ozone dosage is 40 mg / L. Ozone catalytic oxidation tank 6 is filled with transition metal oxides, such as Al 2 O 3 Or CuO commercial solid catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com