Rapid Grinding Method for Rolls in Small Rolling Mills

A technology for grinding and small rolling mills, applied in the field of rolling mill roll grinding, can solve the problems of difficult separation operations, consumption of manpower and time, and impact on assembly accuracy, so as to reduce the processing cycle of grinding rolls, reduce operation time, and save money. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

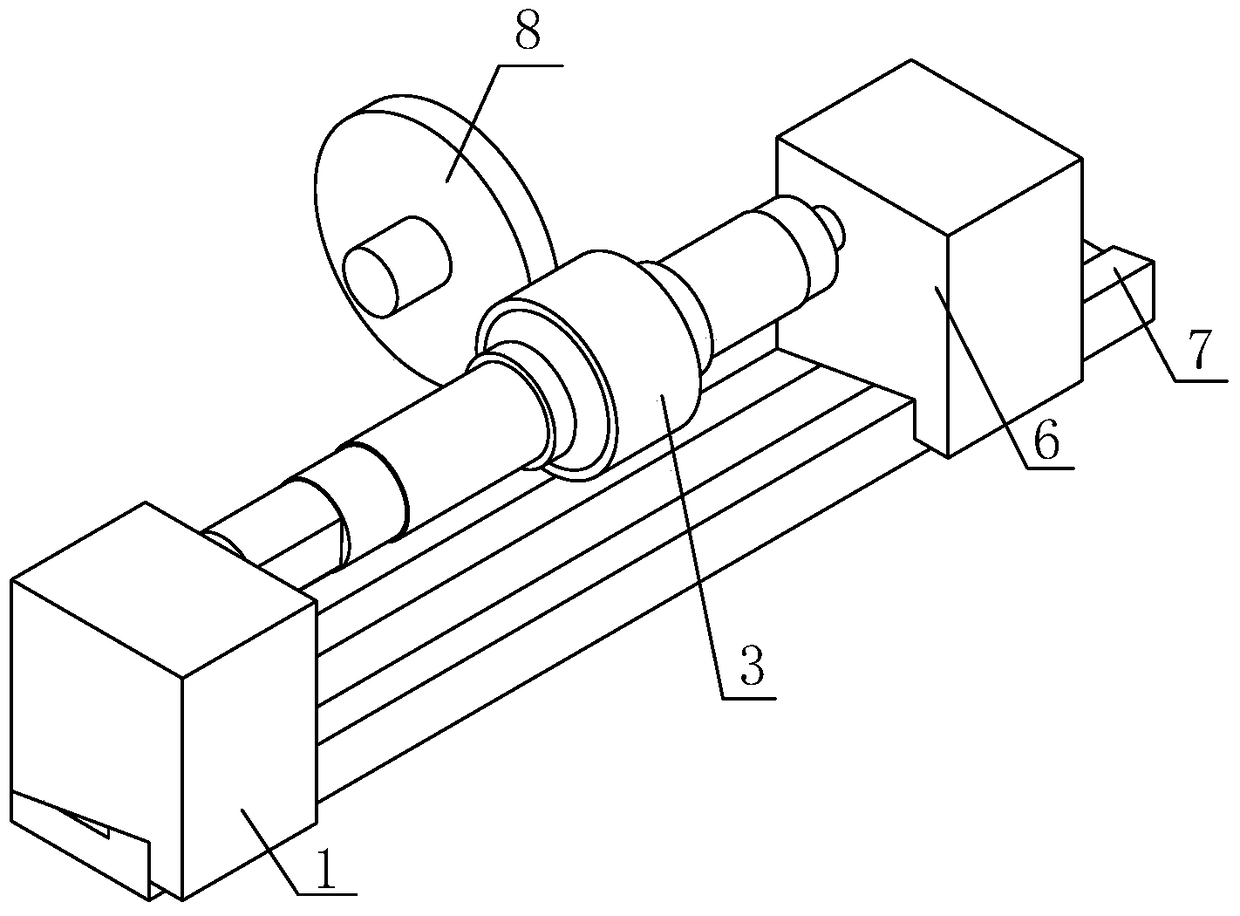

[0030] like figure 1 The shown schematic diagram of the prior art roll grinding process has been described in detail in the background art, and will not be repeated here.

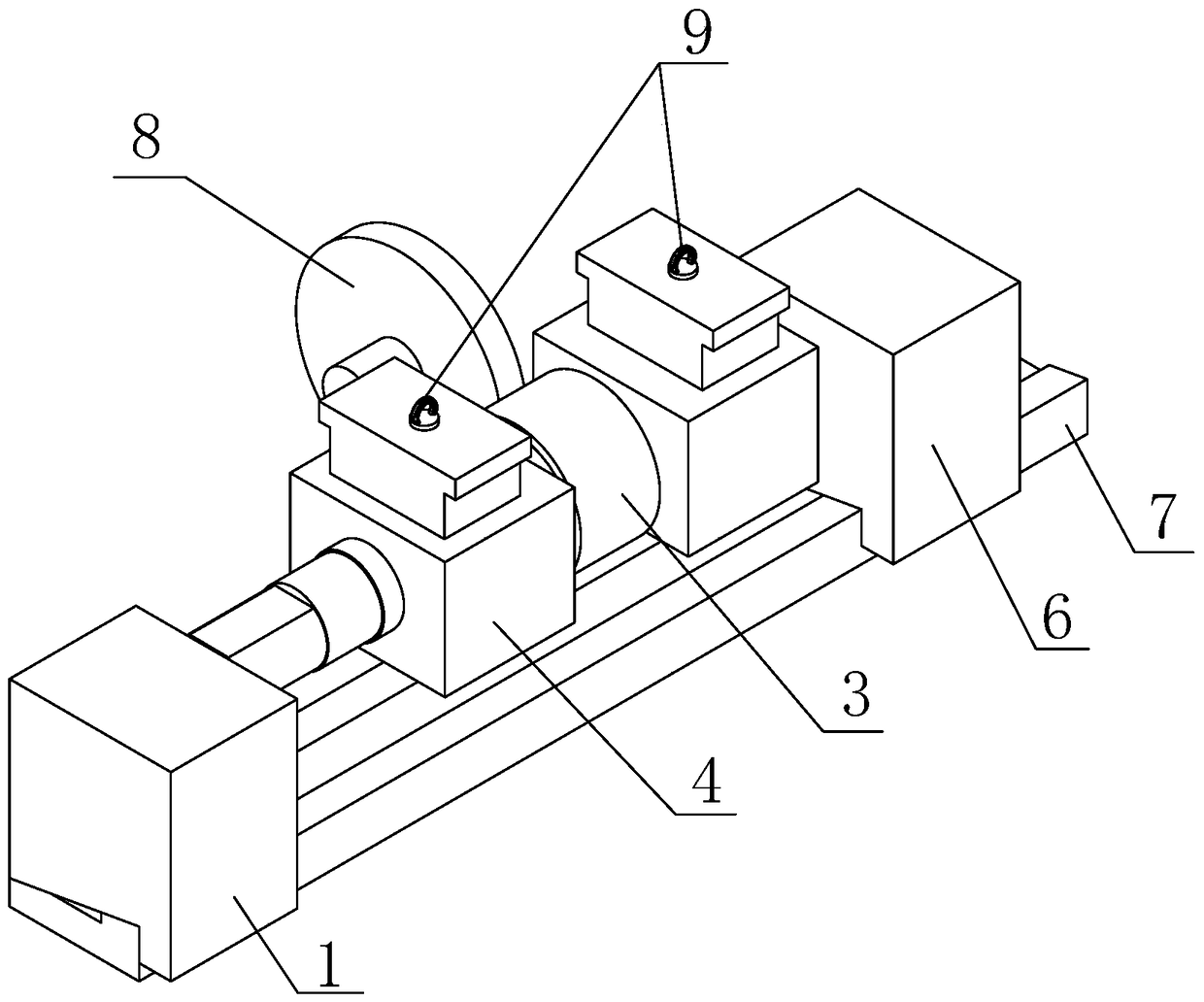

[0031] like Figure 2 to Figure 8 As described, the present embodiment provides a method for rapid grinding of small rolling mill rolls, comprising the following steps:

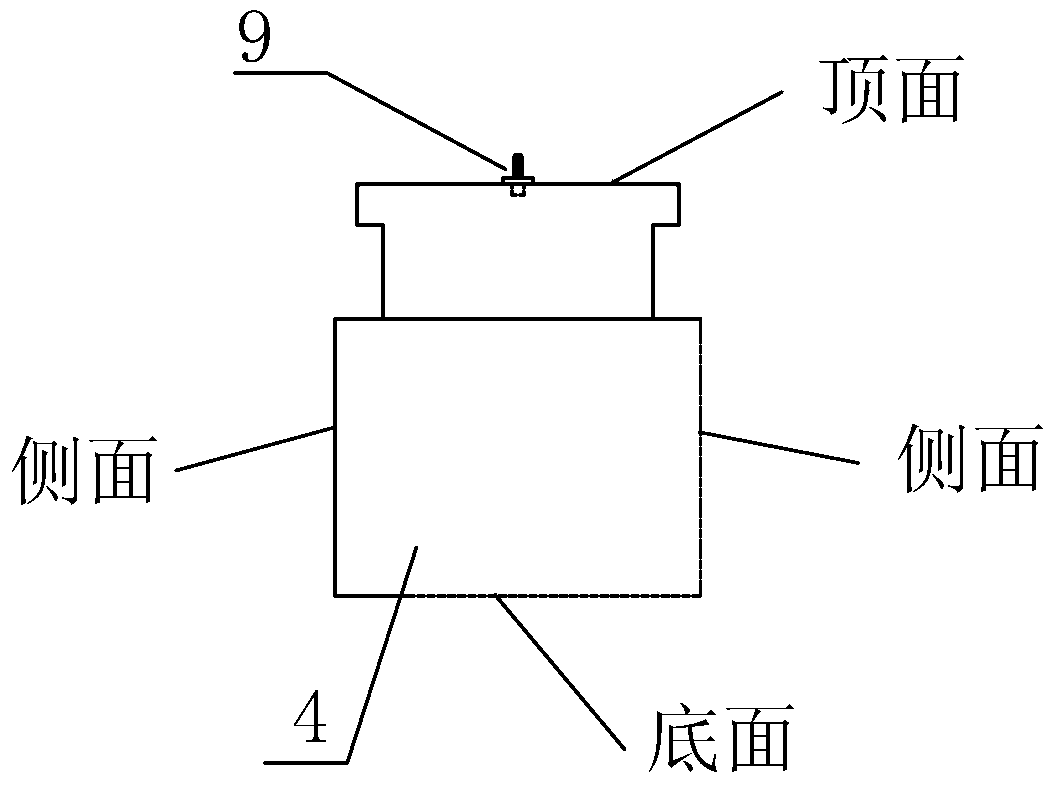

[0032] 1) After the roll 3 is pulled out from the rolling mill, the blind cover of the bearing seat 4 is removed to expose the top hole of the roll 3;

[0033] 2) First process a threaded hole on the top surface of each bearing seat 4, and then fix the lifting ring 9 on the top surface of the bearing seat 4 through the bolts matched with the threaded hole, for hoisting the roll 3 and bearing seat 4;

[0034] 3) Hang the roll 3 and the bearing housing 4 together on the roll grinder, the headstock 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com