Halogen-free soldering flux in solder stick for automatic soldering robot and preparation method

An automatic welding and robot technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of high insulation resistance and low residue, achieve high surface insulation resistance, improve wetting force, and enhance reliability The effect of solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

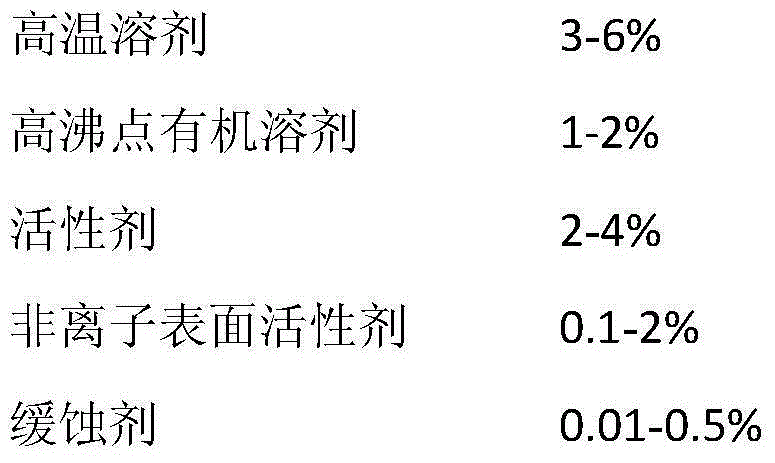

[0025] Raw materials and mass percentages are as follows:

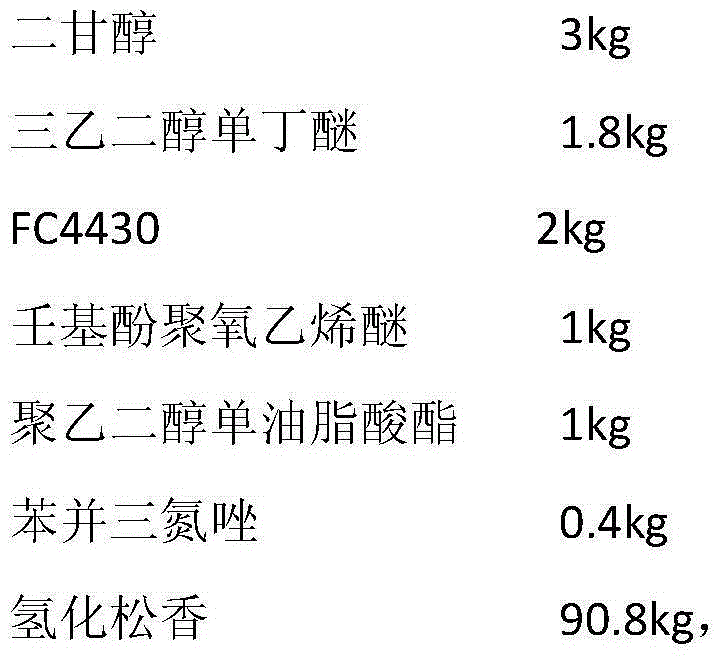

[0026]

[0027] Add 90.8kg of hydrogenated rosin into the container, heat and stir until completely melted, then add 2kg of FC4430, 1kg of nonylphenol polyoxyethylene ether, 1kg of polyethylene glycol monooleate, 0.4 kg of benzotriazole, 3kg of diethylene glycol and 1.8kg of triethylene glycol monobutyl ether, continue to stir for 30 minutes, let stand for 3 minutes, and make a kind of solder for automatic welding robot after filtering with a 200-mesh filter screen Halogen-free flux in wire Halogen-free flux. Pour the flux prepared above into the rosin barrel of the extrusion machine, extrude it into the solder wire at a temperature of 130°C and an air pressure of 0.15MPa, the flux accounts for 2.4% by weight of the solder alloy, and draw it through a wire drawing machine Solder wire with a wire diameter of Φ0.6mm was produced, and the performance test results are shown in Table 1.

Embodiment 2

[0029] Raw materials and mass percentages are as follows:

[0030]

[0031]

[0032] Add 90.49kg of water-white rosin into the container, heat and stir until completely melted, then add 2.5kg of FSN100, 0.5kg of nonylphenol polyoxyethylene ether, and 0.5kg of polyethylene glycol monoester at 135°C Ester, 0.01kg of methyl benzotriazole, 4kg of propylene glycol butyl ether and 2kg of diethylene glycol monohexyl ether, continue to stir for 40 minutes, let stand for 5 minutes, filter with a 200-mesh filter screen to make a The invention discloses a halogen-free flux in a solder wire for an automatic welding robot. Pour the flux prepared above into the rosin barrel of the extruder, extrude it into the solder wire at a temperature of 135°C and an air pressure of 0.18MPa, the flux accounts for 2.3% by weight of the solder alloy, and draw it through a wire drawing machine Solder wire with a wire diameter of Φ0.8mm was produced, and the performance test results are shown in Tabl...

Embodiment 3

[0034] Raw materials and mass percentages are as follows:

[0035]

[0036] Add 80kg of hydrogenated rosin and 10.25kg of disproportionated rosin into the container, heat and stir until completely melted, then add 2.5kg of FC4430, 0.5kg of NP-9, and 0.5kg of nonylphenol polyoxyethylene at a temperature of 140°C Ether, the hydroxybenzotriazole of 0.25kg, the diethyl succinate of 4.5g, the triethylene glycol monobutyl ether of 1kg and the triethyl carbitol ether of 0.5kg, continue stirring for 45 minutes, stand still for 5 minutes After filtering with a 200-mesh filter screen, a halogen-free flux in solder wire for automatic welding robots is made. Pour the flux prepared above into the rosin barrel of the extruder, extrude it into the solder wire at a temperature of 140°C and an air pressure of 0.18MPa, the flux accounts for 2.5% by weight of the solder alloy, and draw it through a wire drawing machine Solder wire with a wire diameter of Φ1.0mm was produced, and the performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com