Activated brown coal and coking wastewater treatment process applying activated brown coal

A treatment process and a technology for activating lignite, which is applied in the direction of adsorption water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption and low removal rate, and achieve lightening treatment Load, good adsorption effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

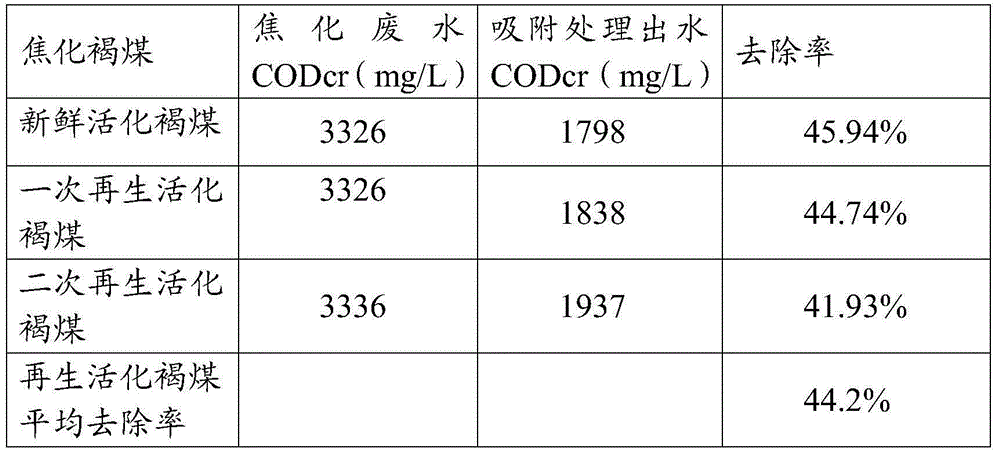

Embodiment 1

[0037] A treatment process for activated lignite and coking wastewater using the activated lignite, wherein the activated lignite is activated with an alkaline solution for the mineral lignite, and the specific activation steps are as follows:

[0038] Firstly, the mineral lignite is first crushed into particles with a particle size of 5mm to 8mm, and then the lignite particles are placed in a corrosion-resistant container, and then 10wt% NaOH solution is added to soak the lignite. The volume ratio of the two is NaOH solution: lignite Particles=3:1, soaking time 24h; the lignite activated by the above-mentioned lye is taken out from the lye and washed with tap water to neutrality, then placed in a blast drying oven at 105°C and dried to constant weight;

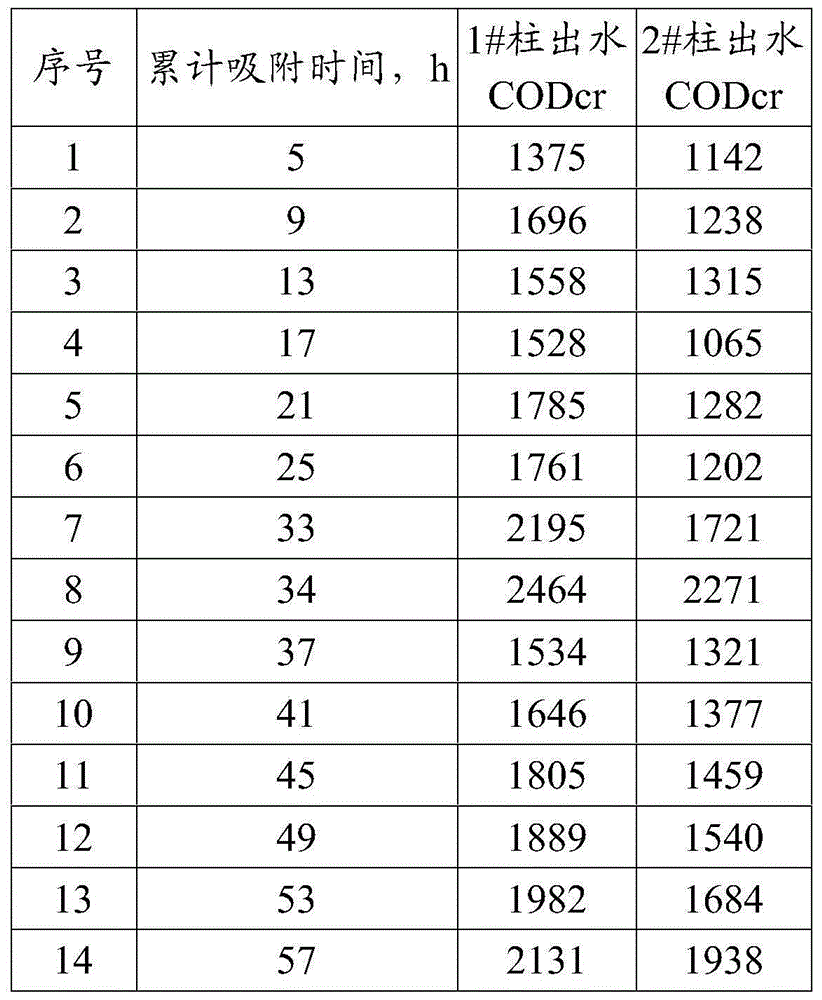

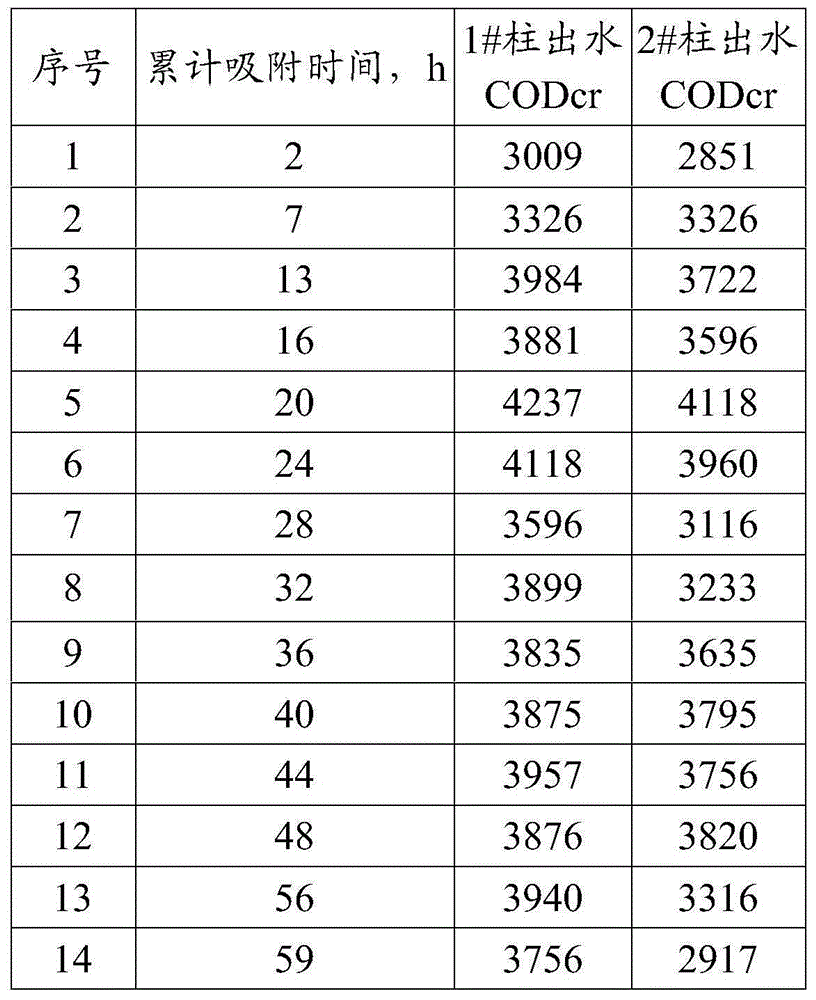

[0039] Apply the above-mentioned coking wastewater treatment process of activated lignite, the specific steps are as follows: After the coking wastewater is pretreated by cooling, adjustment, oil separation and coagulation air...

Embodiment 2

[0043] A treatment process for activated lignite and coking wastewater using the activated lignite, wherein the activated lignite is activated with an alkaline solution for the mineral lignite, and the specific activation steps are as follows:

[0044] Firstly, the mineral lignite is crushed into particles with a particle size of 8 mm to 10 mm, and then the lignite particles are placed in a corrosion-resistant container, and then 20 wt % of NaOH solution is added to soak the lignite. The volume ratio of the two is NaOH solution: lignite Particles = 2:1, soaking time 24h; the lignite activated by the above alkaline solution is taken out from the alkaline solution, washed with tap water until neutral, and then dried in a blast drying oven at 105°C until it reaches a constant weight. ;

[0045] Apply the above-mentioned coking wastewater treatment process of activated lignite, the specific steps are as follows: After the coking wastewater is pretreated by cooling, adjustment, oil...

Embodiment 3

[0051] A treatment process for activated lignite and coking wastewater using the activated lignite, wherein the activated lignite is activated with an alkaline solution for the mineral lignite, and the specific activation steps are as follows:

[0052] First, the mineral lignite is crushed into particles with a particle size of 9mm to 10mm, and then the lignite particles are placed in a corrosion-resistant container, and then 30wt% NaOH solution is added to soak the lignite. The volume ratio of the two is NaOH solution: lignite Particles = 1:1, soaking time 24h; the lignite activated by the above lye is taken out of the lye, washed with tap water until neutral, and then dried in a blast drying oven at 105°C to constant weight.

[0053] Apply the above-mentioned coking wastewater treatment process of activated lignite, the specific steps are as follows: After the coking wastewater is pretreated by cooling, adjustment, oil separation and coagulation air flotation, first use activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com