Antifreeze agent for fresh frozen shrimp

A technology of antifreeze and shrimp, which is applied in the field of quality safety and control of aquatic products, can solve problems such as hidden safety hazards, high sweetness and heat, excessive phosphorus content, etc., to reduce mechanical damage, increase non-freezing water content, and improve Effect of Glass Transition Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

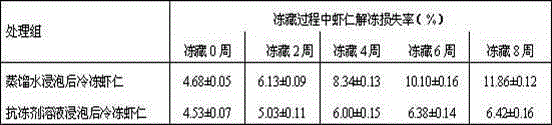

Embodiment 1

[0012] (1) Indian gum and whey protein isolate are mixed at a weight ratio of 1:0.5, then dissolved in distilled water, stirred magnetically for 2 hours, and the pH of the system is adjusted to 6.5, and the resulting solution is frozen at -40°C for 24 hours, then freeze-dried for 24 hours, and ground into pink. The obtained powder was reacted at a temperature of 60°C and a relative humidity of 70% for 4 days; a saccharification product of gum ghatti and whey protein isolate was obtained;

[0013] (2) Weigh 50 g of the saccharification reaction product of gum ghatti and whey protein isolate, slowly add a certain amount of distilled water to dissolve, then adjust the pH value to 7.5, temperature at 80°C, and magnetically stir for 20 minutes. After the solution was cooled to room temperature, 10 g of erythritol was added, magnetically stirred for 20 min, and degassed in vacuum at 0.08 MPa for 60 min.

[0014] (3) Fresh shrimps are suddenly killed in ice temperature, remove the h...

Embodiment 2

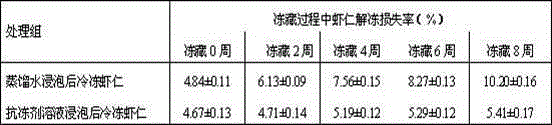

[0018] (1) Mix psyllium gum and sunflower meal protein isolate at a weight ratio of 1:1, then dissolve in distilled water, stir magnetically for 2.5 hours, adjust the pH of the system to 7.0, and freeze the resulting solution at -50°C for 36 hours, then freeze-dry for 27 hours , ground into powder. The obtained powder was reacted at a temperature of 65°C and a relative humidity of 75% for 6 days; a saccharification product of psyllium seed gum and sunflower meal protein isolate was obtained;

[0019] (2) Weigh 80 g of the saccharification reaction product of psyllium seed gum and sunflower meal protein isolate, slowly add a certain amount of distilled water to dissolve, then adjust the pH value to 8.0, temperature at 85°C, and magnetically stir for 25 minutes. After the solution was cooled to room temperature, 30 g of erythritol was added, magnetically stirred for 25 min, and degassed at 0.095 MPa for 40 min.

[0020] (3) Fresh shrimps are suddenly killed in ice temperature, ...

Embodiment 3

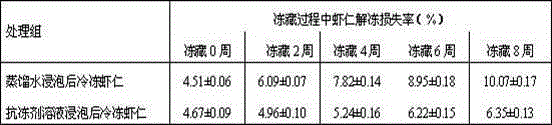

[0024] (1) Inulin and myofibrillar protein were mixed at a weight ratio of 1:1.5, then dissolved in distilled water, stirred magnetically for 3 hours, and the pH value of the system was adjusted to 7.5, and the resulting solution was frozen at -60°C for 30 hours, then freeze-dried for 48 hours, and ground into pink. The obtained powder was reacted at a temperature of 70°C and a relative humidity of 80% for 8 days; the saccharification product of inulin and myofibrillar protein was obtained;

[0025] (2) Weigh 100 g of the saccharification reaction product of inulin and myofibrillar protein, slowly add a certain amount of distilled water to dissolve, then adjust the pH value to 8.5, temperature at 90° C., and magnetically stir for 30 minutes. After the solution was cooled to room temperature, 50 g of erythritol was added, magnetically stirred for 30 min, and degassed in vacuum at 0.01 MPa for 30 min.

[0026] (3) Fresh shrimps are suddenly killed in ice temperature, remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com