A method and device for dismantling lead-plastic separation of waste lead-acid batteries

A lead-acid battery and a separation method technology, applied in the field of mechanical transmission, can solve the problems of low practicability and specificity, great harm to the human body and the environment, difficult to control the separation speed, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

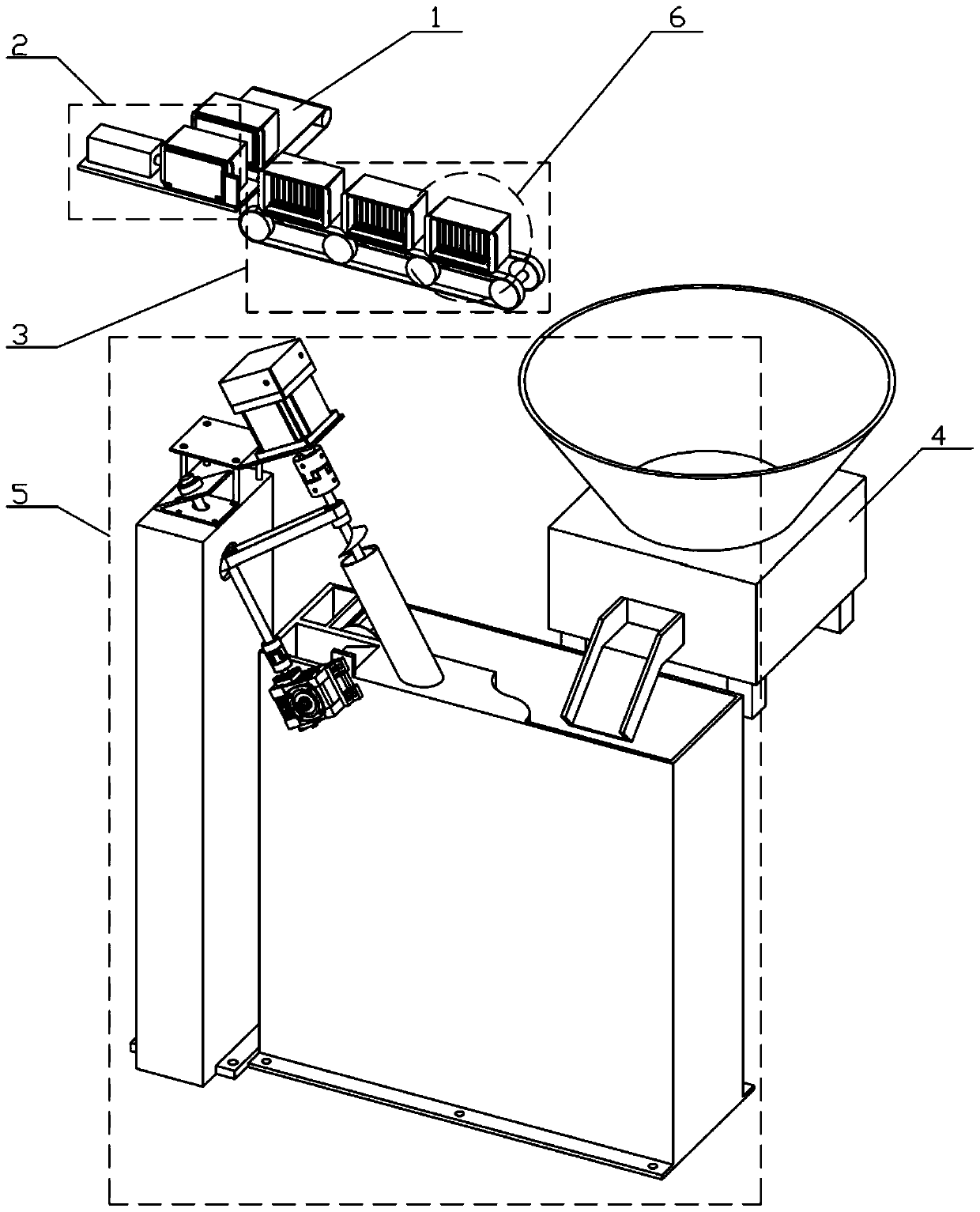

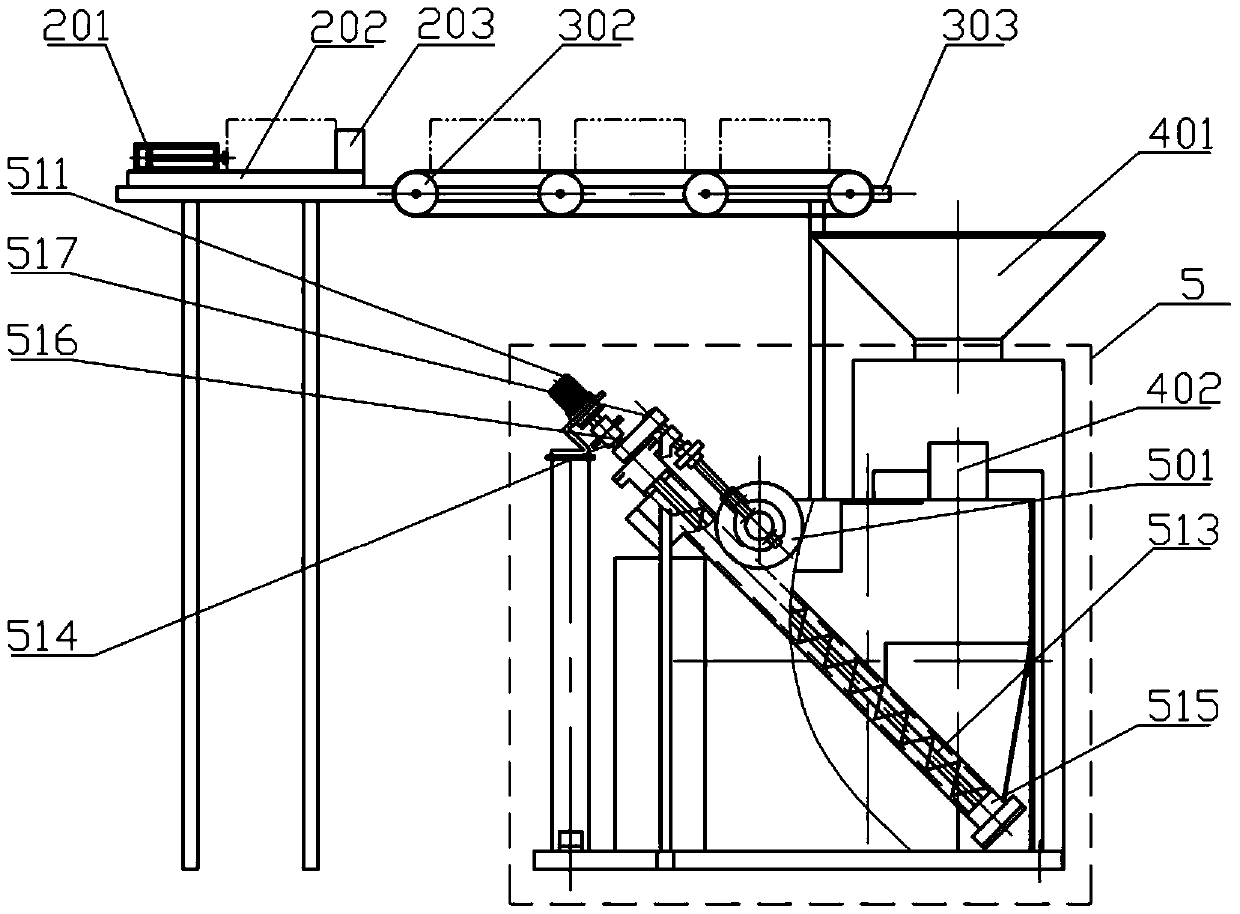

[0023] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

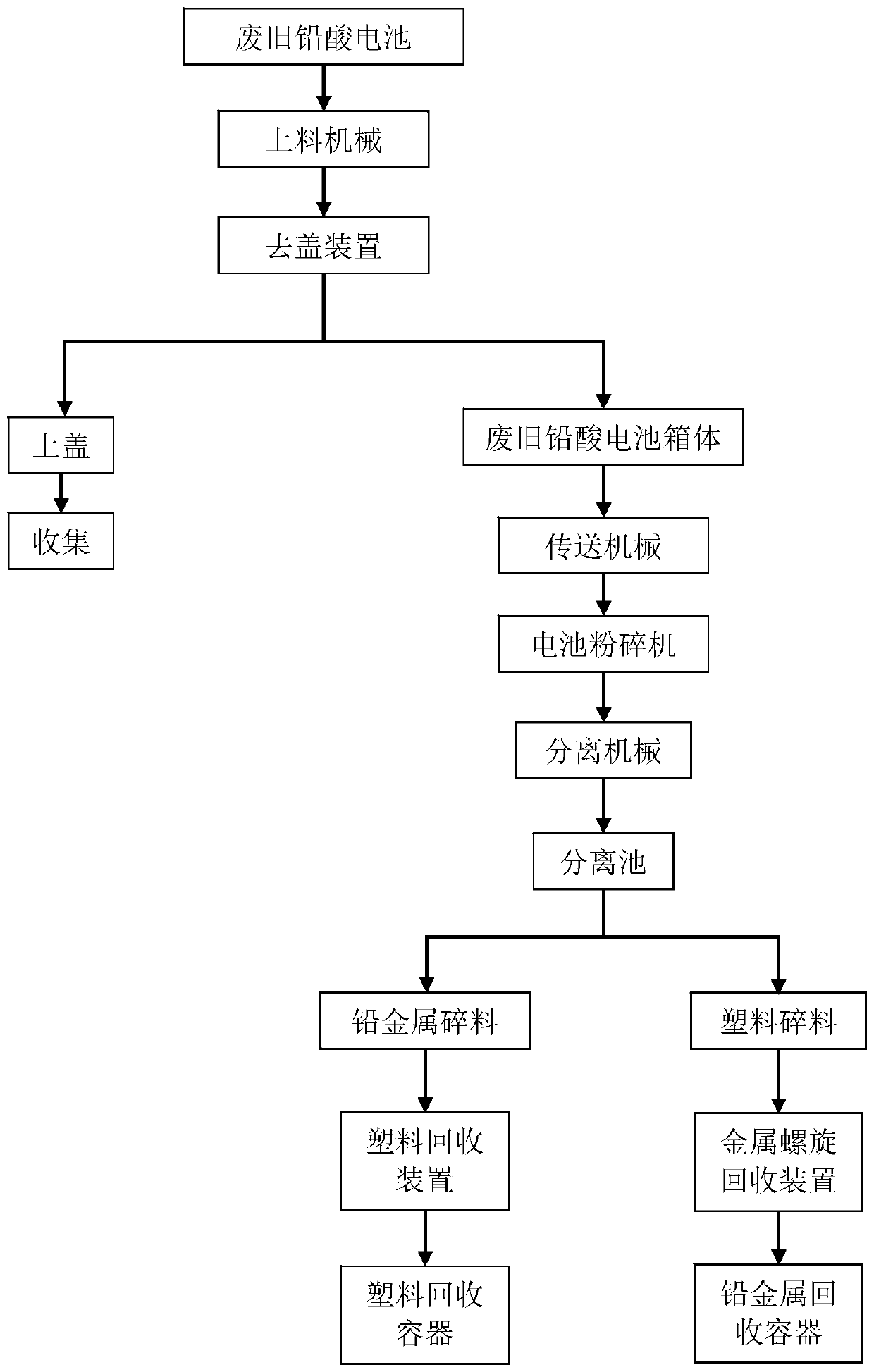

[0024] The waste lead-acid battery of the present invention's design disassembles the lead-plastic separation method (separation method for short, see figure 1 ), the separation method comprises the following processing steps:

[0025] (1). Loading preparation; the waste lead-acid battery is conveyed by the feeding machine and enters the working position of the cover removal machine;

[0026] (2). Remove the upper cover; the cover removal machine uses the reciprocating mechanism to cooperate with the stopper fixed on the support frame of the cover removal machine, and uses extrusion to remove the upper shell of the waste lead-acid battery, and the upper cover of the waste lead-acid battery is removed by the cover removal machine Collection, the used lead-acid battery box is pushed into the transmission machine by the reciprocating mechanism;

[0027] (3). Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com