Method for coating paper substrate with silicon dioxide directly

A technology of silica and coated paper, which is applied in the direction of coated paper base paper, etc., can solve the problems of limiting the characteristics of silica gel particles and the scarcity of silica content, etc., and achieve uniform paper surface properties, easy operation, and easy access to raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

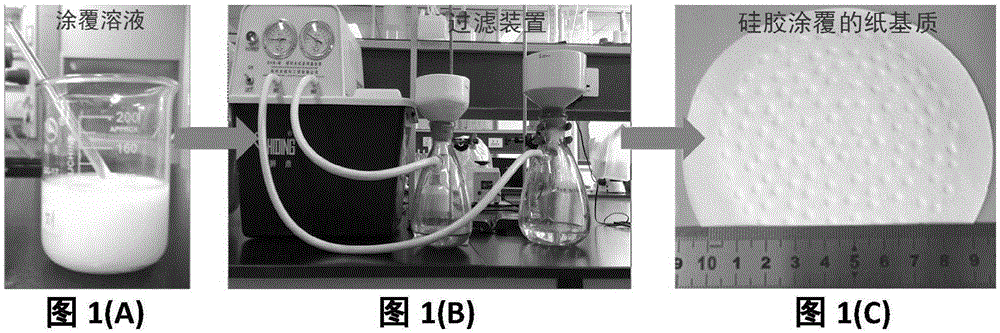

[0029] The present embodiment is that the silica-coated paper matrix is prepared by the suction filtration coating method, comprising the following steps:

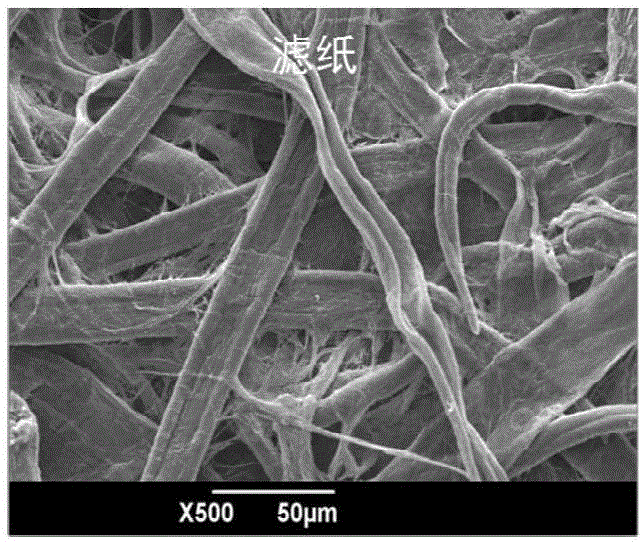

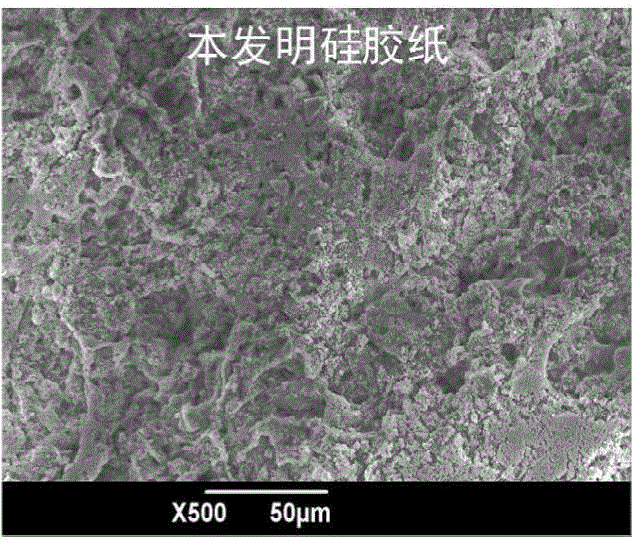

[0030]Referring to Figure 1, at room temperature, add 0.15g of soluble starch and 100mL of deionized water into a 250mL beaker, and stir it evenly with a glass rod; then place it in a heating mantle for heat treatment, and continue stirring during the heating process to The starch is fully dissolved; after the starch is completely dissolved, take the beaker out of the heating device and cool it to room temperature, add 0.6g of silicon dioxide (purity: 99.99%) with a particle size of about 1.0 μm and stir evenly, then put it into a ultrasonic emulsification device Ultrasonic treatment was carried out for 15min in the medium to prepare the coating solution as shown in Figure 1(A); then the above solution was added to the device as shown in Figure 1(B) containing blank filter paper for suction filtration coating, and the sol...

Embodiment 2

[0034] The present embodiment is that the silica-coated paper matrix is prepared by the suction filtration coating method, comprising the following steps:

[0035] At room temperature, add 0.10g of soluble starch and 100mL of deionized water into a 250mL beaker, and use the same steps as in Example 1 for the rest. After heating, dissolving, and cooling, add 0.6g of carbon dioxide with a particle size of about 1.0μm. Silica, after suction filtration, washing, drying, pressing and other steps can prepare the silica coated paper substrate.

Embodiment 3

[0037] The present embodiment is that the silica-coated paper matrix is prepared by the suction filtration coating method, comprising the following steps:

[0038] At room temperature, in a 250mL beaker, add 0.15g of soluble starch and 100mL of deionized water, and use the same steps as in Example 1 for the rest. After heating, dissolving, and cooling, add 0.4g of carbon dioxide with a particle size of about 1.0μm. Silica, after suction filtration, washing, drying, pressing and other steps can prepare the silica coated paper substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com