Preparation method of sericulture fiber material

A fiber material and sericulture technology, which is applied in the field of preparation of silk fiber materials, can solve the problems of inability to release active groups, no formation of composite fibers, and no research on the reaction between cellulose fibers and silk fibers, so as to avoid partial breakage and no allergies Original, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

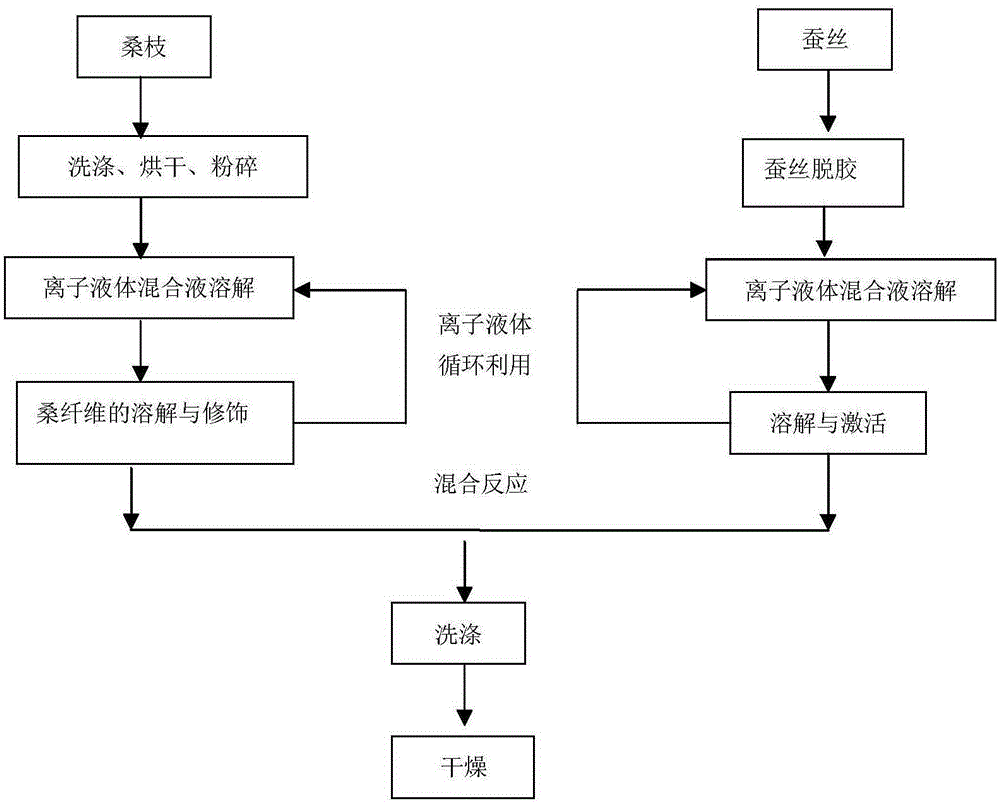

[0025] The invention provides a kind of preparation method of silkworm and mulberry fiber material, and preparation process is as follows figure 1 shown, including the following steps:

[0026] (1) Take mulberry branches, wash, dry, and crush to obtain mulberry branch powder, mix and dissolve the obtained mulberry branch powder with the ionic liquid mixture, keep it warm at 40°C to 95°C, then add additives, stir and heat treatment, and obtain product A ;

[0027] (2) Mix the degummed silk fiber and the ionic liquid mixture evenly, heat treatment to obtain the product B,

[0028] (3) Mix the product A and product B obtained in steps (1) and (2), heat and stir at 40°C to 95°C to react evenly, and obtain a sample;

[0029] (4) adding the sample obtained in step (3) to a fiber regeneration reagent to wash and remove the liquid reagent in the sample, recovering the ionic liquid in the liquid reagent, and obtaining the silkworm fiber after the solid is freeze-dried.

Embodiment 1

[0032] Example 1 Preparation of ionic liquid mixture ([EMIM][DEP] mixture).

[0033] Mix 5g of ionic liquid [EMIM][DEP] and 5g of NMMO uniformly, and heat with magnetic stirring at 90°C to obtain an ionic liquid mixture.

Embodiment 2

[0034] Example 2 Preparation of ionic liquid mixture ([EMIM][DEP] mixture).

[0035] Mix 5g of ionic liquid [EMIM][DEP] and 4g of NMMO evenly, add 1g of water, and heat with magnetic stirring at 90°C to obtain an ionic liquid mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com