Metalorganic chemical vapor deposition (MOCVD) equipment and method for removing parasitic particles thereof

A particle removal and equipment technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems affecting product quality, reducing production efficiency, affecting device surface film growth morphology, etc., to ensure film growth Quality, pollution reduction, and the effect of increasing film growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

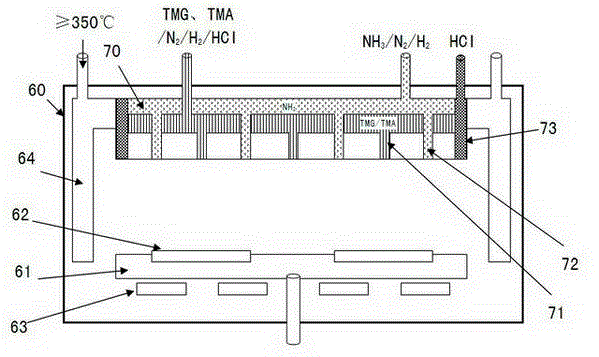

[0048] A first example is provided below, using the gases TMG and NH 3 As a reactive source, H 2 As carrier gas, HCl as cleaning gas; cleaning gas HCl and two reaction sources TMG and NH 3 The reactions between are:

[0049] Ga(CH 3 ) 3 +HCl→GaCl+CH 4 +C 2 h 6 +H 2 ;

[0050] GaCl+NH 3 →GaN+HCl+H 2 (reusable);

[0051] NH 3 +HCl←→NH 4 Cl (gas).

[0052] The reaction between the cleaning gas HCl and the parasitic particles of GaN is as follows:

[0053] GaN+HCl+H 2 →GaCl(gas)+NH 4 Cl; Ga+HCl→GaCl+1 / 2H 2 ;

[0054] It can be seen that the use of cleaning gas to decompose parasitic particles in the present invention will not affect the original process in the reaction chamber, and the gaseous GaCl obtained after the reaction can be discharged from the reaction chamber through the exhaust device of the MOCVD equipment together with other tail gases for processing or reuse. .

[0055] A second example is provided below, using the gases TMA and NH 3 As a reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com