A kind of toughened benzoxazine composite material and preparation method thereof

A technology of benzoxazine and toughening modification, which is applied in the field of new functional polymer materials and its preparation, can solve problems such as easy agglomeration, and achieve the effects of simple process, improved interface compatibility, and strong chemical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

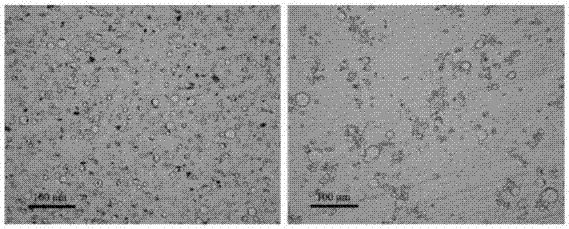

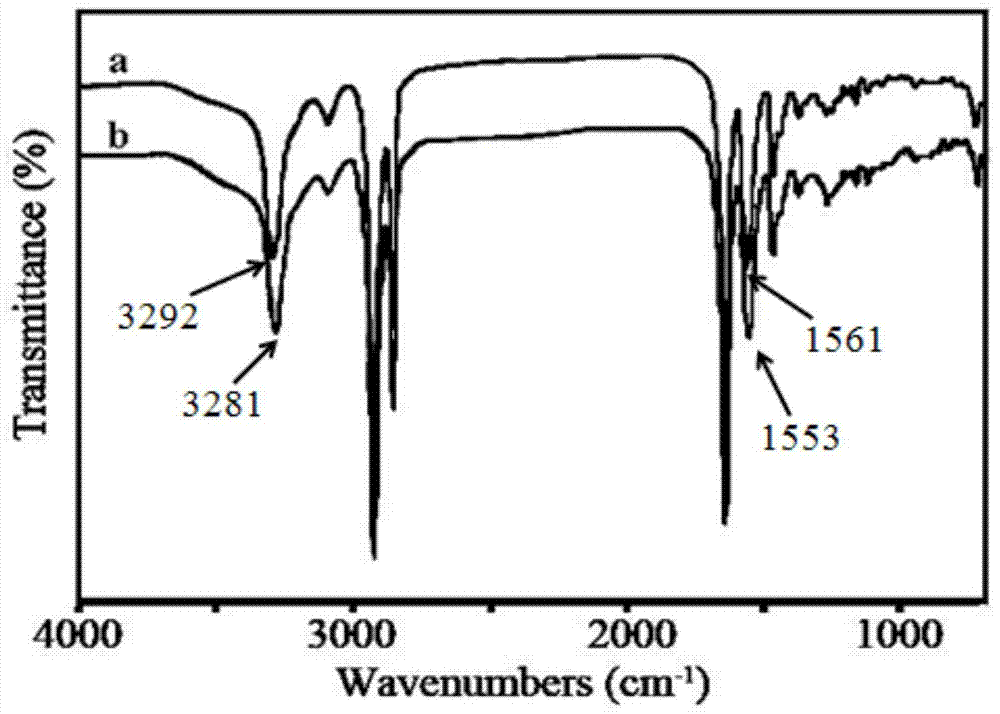

Image

Examples

Embodiment 1

[0044] Weigh 1 part of graphite powder with a particle size of 30 microns and add it to a reaction flask containing 100 ml of concentrated sulfuric acid. Keep the temperature of the graphite powder-concentrated sulfuric acid reaction system at 5°C. Add 1 part of sodium nitrate (NaNO 3 ) and 6 parts potassium permanganate (KMnO 4 ). After the potassium permanganate and sodium nitrate were completely dissolved, the temperature in the reaction flask was raised to 35°C. After continuing the reaction at a constant temperature for 2 hours, 90 ml of deionized water was slowly added to the reaction flask. After stirring and reacting for 20 minutes, sonicate at room temperature at 40 Hz for 20 minutes, and switch to magnetic stirring. Add 20 ml of 35% hydrogen peroxide dropwise into the reaction bottle to obtain a graphene oxide suspension. The graphene oxide suspension was centrifuged at 10,000 rpm, and the lower sediment was the crude product of graphene oxide. The crude graphe...

Embodiment 2

[0050] Weigh 5 parts of graphite powder with a particle size of 30 microns and add to a reaction flask containing 120 milliliters of concentrated sulfuric acid. Keep the temperature of the graphite powder-concentrated sulfuric acid reaction system at 3°C. Add 0.5 parts of sodium nitrate (NaNO 3 ) and 15 parts potassium permanganate (KMnO 4 ). After the potassium permanganate and sodium nitrate were completely dissolved, the temperature in the reaction flask was raised to 40°C. After continuing the reaction at a constant temperature for 5 hours, slowly add 100 ml of deionized water into the reaction flask. After stirring and reacting for 60 minutes, ultrasonication was performed at room temperature at 40 Hz for 20 minutes, and the stirring was switched to magnetic force. Add 50 ml of 35% hydrogen peroxide dropwise into the reaction bottle to obtain a graphene oxide suspension. The graphene oxide suspension was centrifuged at 10,000 rpm, and the lower sediment was the crude...

Embodiment 3

[0054] Weigh 2 parts of graphite powder with a particle size of 40 microns and add to a reaction flask containing 80 milliliters of concentrated sulfuric acid. Keep the temperature of the graphite powder-concentrated sulfuric acid reaction system at 0°C. Add 1 part of sodium nitrate (NaNO 3 ) and 6 parts potassium permanganate (KMnO 4 ). After the potassium permanganate and sodium nitrate were completely dissolved, the temperature in the reaction flask was raised to 30°C. After continuing the reaction at a constant temperature for 5 hours, 40 ml of deionized water was slowly added to the reaction flask. After stirring and reacting for 30 minutes, sonicate at room temperature at 40 Hz for 20 minutes, and switch to magnetic stirring. Add 40 ml of 35% hydrogen peroxide dropwise into the reaction flask to obtain a graphene oxide suspension. The graphene oxide suspension was centrifuged at 10,000 rpm, and the lower sediment was the crude product of graphene oxide. The crude g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com