Flame-retardant ABS (acrylonitrile butadiene styrene) composite and preparation method thereof

A technology of composite materials and mixtures, which is applied in the field of flame-retardant materials, can solve the problems of limiting the application of flame-retardant ABS materials, poor physical properties, complex components, etc., and achieve the effect of excellent mechanical properties, high surface energy, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

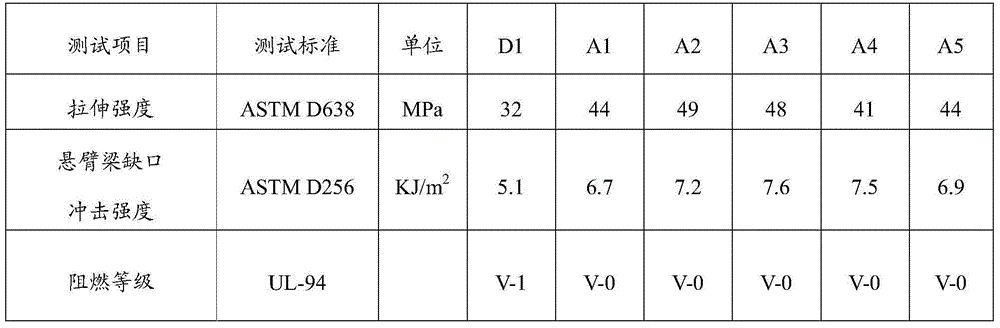

Embodiment 1

[0028] (1) Weigh 70 parts of ABS, 16 parts of LDH-SEP, 8 parts of APP, 10 parts of PER, 0.05 parts of Irganox168 and 0.05 parts of Irganox1010, mix and stir evenly to obtain a mixture;

[0029] (2) Put the mixture obtained in step (1) into the hopper of the twin-screw extruder to extrude and granulate to obtain the flame-retardant ABS composite material A1, wherein the first temperature zone of the twin-screw extruder The temperature is 190°C, the temperature in the second temperature zone is 230°C, the temperature in the third temperature zone is 230°C, the temperature in the fourth temperature zone is 230°C, the temperature in the fifth temperature zone is 230°C, and the temperature in the sixth temperature zone The temperature is 230° C., the head temperature of the twin-screw extruder is 230° C., and the screw speed is 200 r / min.

Embodiment 2

[0031] (1) Weigh 90 parts of ABS, 24 parts of LDH-SEP, 12 parts of APP, 16 parts of PER, 0.3 parts of Irganox1010 and 0.2 parts of Irganox1330, mix and stir evenly to obtain a mixture;

[0032] (2) Put the mixture obtained in the step (1) into the hopper of the twin-screw extruder and extrude and granulate to obtain the flame-retardant ABS composite material A2, wherein the first temperature zone of the twin-screw extruder The temperature is 210°C, the temperature in the second temperature zone is 270°C, the temperature in the third temperature zone is 270°C, the temperature in the fourth temperature zone is 270°C, the temperature in the fifth temperature zone is 270°C, and the temperature in the sixth temperature zone The temperature is 270° C., the head temperature of the twin-screw extruder is 270° C., and the screw speed is 260 r / min.

Embodiment 3

[0034] (1) Weigh 80 parts of ABS, 20 parts of LDH-SEP, 10 parts of APP, 13 parts of PER, 0.1 part of Irganox168 and 0.1 part of Irganox1010, mix and stir evenly to obtain a mixture;

[0035] (2) Put the mixture obtained in the step (1) into the hopper of the twin-screw extruder and extrude and granulate to obtain the flame-retardant ABS composite material A3, wherein the first temperature zone of the twin-screw extruder The temperature is 200°C, the temperature in the second temperature zone is 250°C, the temperature in the third temperature zone is 250°C, the temperature in the fourth temperature zone is 250°C, the temperature in the fifth temperature zone is 250°C, and the temperature in the sixth temperature zone is 250°C. The temperature is 250° C., the head temperature of the twin-screw extruder is 250° C., and the screw speed is 230 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com