High-infrared-emitting-ability cordierite-spinel ceramic material and preparation method thereof

A technology of infrared emissivity and ceramic materials, which is applied in the field of ceramic material preparation, can solve the problems of complex raw materials, unstable finished product quality, and high cost, and achieve high emissivity, good economic and social benefits, and good thermal shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

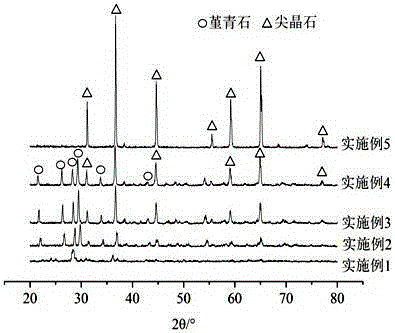

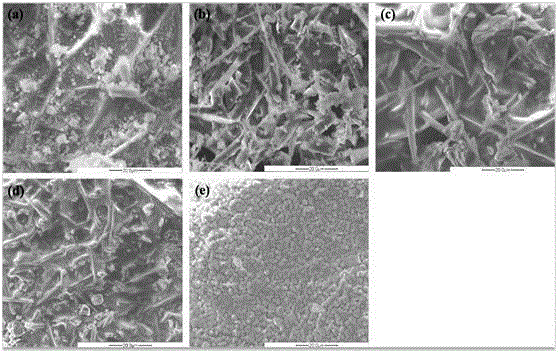

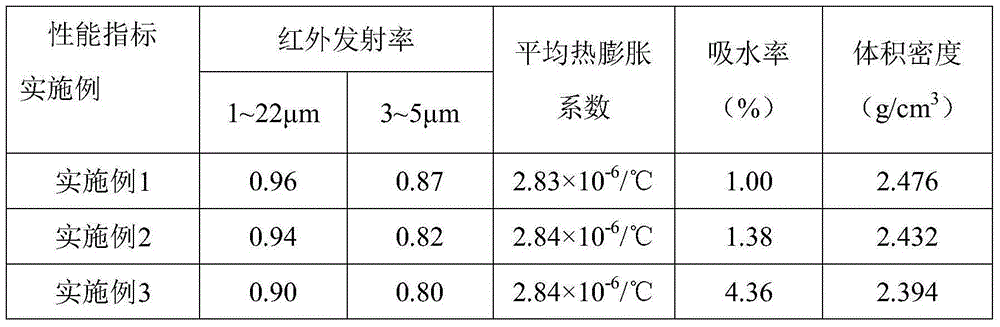

Embodiment 1

[0036] A cordierite-spinel infrared ceramic material with high infrared emissivity is composed of raw materials: 77wt% of fly ash, 13wt% of magnesium oxide and 10wt% of aluminum oxide.

[0037] The manufacture method of the cordierite-spinel infrared ceramic material with above-mentioned high infrared emissivity is as follows:

[0038] 1) Fly ash is dried and ball milled to obtain a powder with a fineness not greater than 30 μm. Fly ash, industrial magnesium oxide, and aluminum oxide are mixed in parts by mass of 77wt%, 13wt%, and 10wt%, respectively, and stirred evenly form a mixture;

[0039] 2) Put the mixture into a ball mill jar, add agate balls, the mass ratio of agate balls to the mixture is 20:1, and add an appropriate amount of ethanol (just make the mixture into a slurry), and then put it on the planetary ball mill Ball mill at a speed of 300r / min for 8 hours, and stop for 20 minutes to cool after grinding for 1 hour; after grinding, pour the raw materials into a be...

Embodiment 2

[0046] A cordierite-spinel infrared ceramic material with high infrared emissivity, the raw materials of which are composed of 70wt% of fly ash, 15wt% of magnesium oxide and 15wt% of aluminum oxide.

[0047] The manufacture method of the cordierite-spinel infrared ceramic material with above-mentioned high infrared emissivity is as follows:

[0048] 1) Fly ash is dried and ball milled to obtain a powder with a fineness not greater than 30 μm. Fly ash, industrial magnesium oxide, and alumina are mixed in parts by mass of 70wt%, 15wt%, and 15wt%, respectively, and stirred evenly form a mixture;

[0049] 2) Put the mixture into a ball mill jar, add agate balls, the mass ratio of agate balls to the mixture is 20:1, and add an appropriate amount of ethanol (just make the mixture into a slurry), and then put it on the planetary ball mill Ball mill at a speed of 350r / min for 7.5 hours, and stop for 20 minutes to cool for every 1 hour; after grinding, pour the raw materials into a be...

Embodiment 3

[0056] A cordierite-spinel infrared ceramic material with high infrared emissivity, the raw materials of which are composed of 65wt% of fly ash, 15wt% of magnesium oxide and 20wt% of aluminum oxide.

[0057] The manufacture method of the cordierite-spinel infrared ceramic material with above-mentioned high infrared emissivity is as follows:

[0058] 1) Fly ash is dried and ball milled to obtain a powder with a fineness not greater than 30 μm. Fly ash, industrial magnesium oxide, and alumina are mixed in parts by mass of 65wt%, 15wt%, and 20wt%, respectively, and stirred evenly form a mixture;

[0059] 2) Put the mixture into a ball mill jar, add agate balls, the mass ratio of agate balls to the mixture is 18:1, and add an appropriate amount of ethanol (just make the mixture into a slurry), and then put it on the planetary ball mill Ball mill at a speed of 400r / min for 7 hours, and stop for 20 minutes to cool after grinding for 1 hour; after grinding, pour the raw materials in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com