Ce:YAG glass ceramic as well as preparation method and application thereof

A technology of glass-ceramic and glass frit, which is applied in the field of LED fluorescent materials, can solve the problems of unreasonable material composition design, complex glass-ceramic preparation process, and low transparency of glass-ceramic, and achieve low glass transition temperature and low cost , the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] will analyze pure SiO 2 、H 3 BO 3 , PbO, ZnO, Ce:YAG phosphor, according to 8mol% SiO 2 , 35mol% B 2 o 3 , 46mol%PbO, 11mol%ZnO, 5wt%Ce:YAG phosphors are accurately weighed and placed in an agate mortar, mixed and ground evenly in the agate mortar, placed in a corundum crucible, and then placed in a resistance furnace After heating to 650°C, keep it warm for 1 hour, then take out the glass melt and quickly pour it into a cast iron mold with a temperature of 400°C, then place it in a muffle furnace for annealing, keep it at 350°C for 2 hours, and finally cool it down to 20 ℃ to form transparent Ce:YAG glass-ceramics.

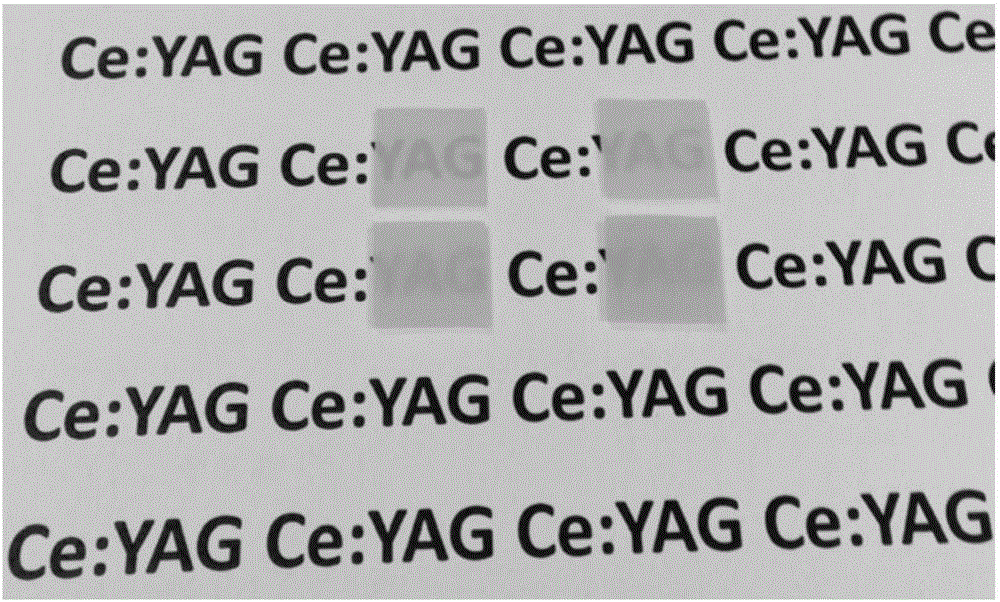

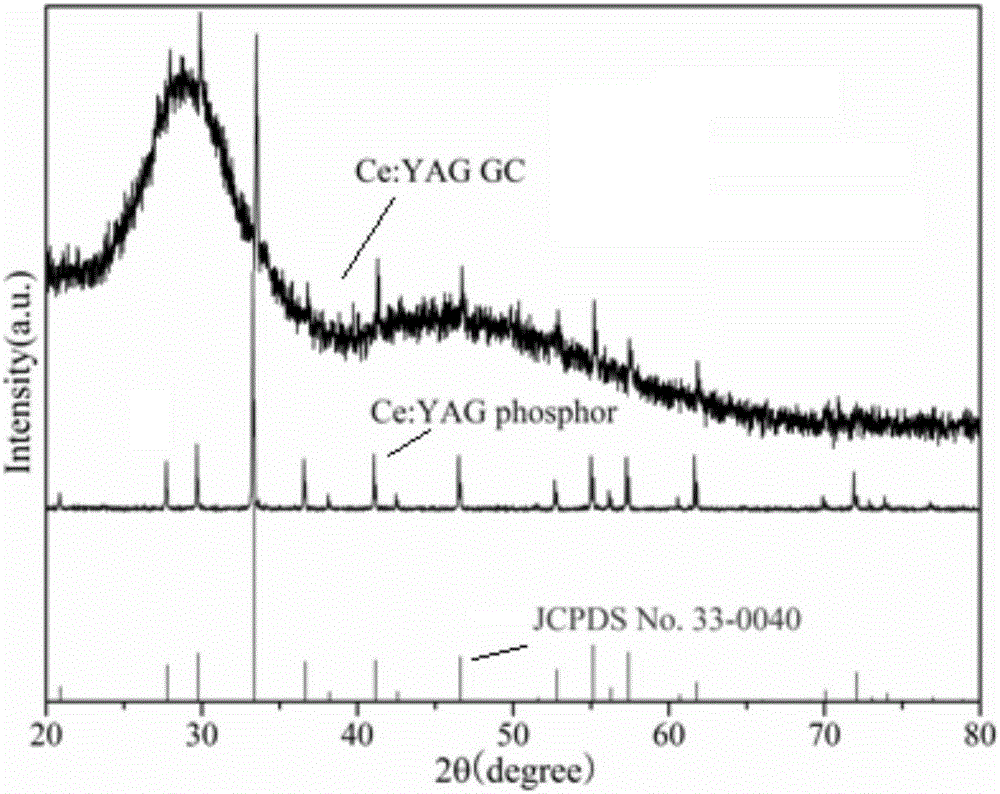

[0043] The prepared transparent Ce:YAG glass-ceramic was tested for its phase and spectral properties, and its XRD pattern is as follows figure 2 As shown, the XRD diffraction peaks of the fluorescent glass sample are consistent with the main diffraction peaks of the standard card of the YAG crystal phase, indicating that the Ce:YAG powder has been ...

Embodiment 2

[0045] will analyze pure SiO 2 、H 3 BO 3 , PbO, ZnO, Ce:YAG phosphor, according to 7mol% SiO 2 , 35mol% B 2 o 3 , 47mol%PbO, 11mol%ZnO, 5wt%Ce:YAG phosphors are accurately weighed and placed in an agate mortar, mixed and ground evenly in the agate mortar, placed in a corundum crucible, and then placed in a resistance furnace After heating to 700°C, keep it warm for 1 hour, then take out the glass melt and quickly pour it into a cast iron mold with a temperature of 400°C, then place it in a muffle furnace for annealing, keep it at 350°C for 2 hours, and finally cool it down to 20 ℃ to form transparent Ce:YAG glass-ceramics.

[0046] Coupling transparent Ce:YAG glass-ceramics with a 460nm blue light chip can emit bright white light under blue light excitation. Excited by a wavelength of 460nm, the emission peak wavelength is located at 538nm, and the luminous efficiency can reach 133lm / W under the excitation of a current of 20mA.

Embodiment 3

[0048] will analyze pure SiO 2 、H 3 BO 3 , PbO, ZnO, Ce:YAG phosphor, according to 6mol% SiO 2 , 35mol% B 2 o 3 , 48mol%PbO, 11mol%ZnO, 5wt%Ce:YAG phosphors are accurately weighed and placed in an agate mortar, mixed and ground evenly in the agate mortar, placed in a corundum crucible, and then placed in a resistance furnace After heating to 750°C, hold it for 1 hour, then take out the glass melt and quickly pour it into a cast iron mold with a temperature of 400°C, then place it in a muffle furnace for annealing, keep it at 350°C for 2 hours, and finally cool it down to 20 ℃ to form transparent Ce:YAG glass-ceramics.

[0049] Coupling transparent Ce:YAG glass-ceramics with a 460nm blue light chip can emit bright white light under blue light excitation. Excited by a wavelength of 460nm, the emission peak wavelength is located at 538nm, and the luminous efficiency can reach 124lm / W under the excitation of a current of 20mA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com