Method and device for producing high-purity magnesium oxide and co-producing industrial concentrated hydrochloric acid through partially hydrated magnesium chloride fluidization pyrolysis

A technology of hydrated magnesium chloride and magnesium oxide, applied in the fields of magnesium oxide, chemical industry, chlorine/hydrogen chloride, etc., can solve the problems of high energy consumption, no fluidized pyrolysis device for fluidized pyrolysis process, low product purity, etc. problem, to achieve the effect of less water vapor content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

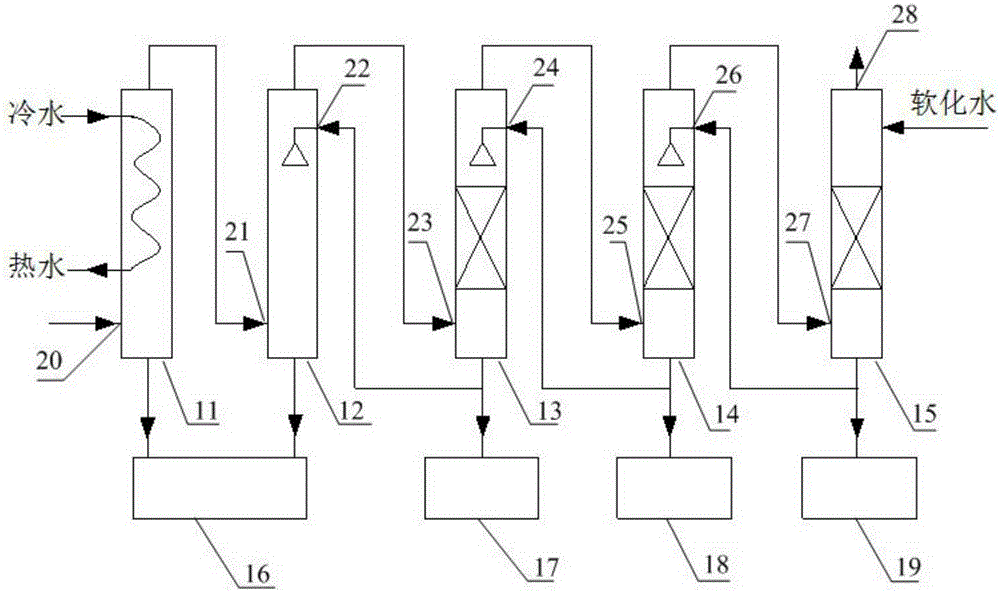

Image

Examples

example 1

[0079] Example 1: Preparation of magnesium oxide by fluidized pyrolysis at 700°C

[0080] Preparation of low hydrated magnesium chloride from halogen grains. Halogen grains are solid materials obtained by evaporating, concentrating and granulating the old brine solution. In addition to the evaporation of water, other chemical components in the brine grains are no different from the old brine. The specific steps of preparing low hydrated magnesium chloride with halogen grains as raw materials are as follows: firstly, dissolve halogen grains in pure water to prepare a saturated liquid, remove color through activated carbon adsorption, use isooctyl alcohol as an extraction agent, and use sulfonated kerosene as a diluent for extraction. After the boron and barium chloride solution precipitated sulfate radical impurities, the magnesium chloride hexahydrate crystals with a purity greater than 99.5% were obtained by evaporation and crystallization, and the magnesium chloride hexahyd...

example 2

[0082] Example 2: Preparation of magnesium oxide by fluidized pyrolysis at 650°C

[0083] The preparation technology of low hydrate magnesium chloride solid particle material is identical with example 1.

[0084] Turn on the power of the air preheater and the electric heating furnace, control the air outlet temperature of the air preheater to 350°C, and control the electric heating furnace so that the temperature in the fluidized bed pyrolysis furnace is 650±10°C. The fluidized bed pyrolysis furnace is made of quartz glass, the inner diameter of the reactor is 40mm, and the height is 1.2m. Open the compressed air source, and control the volume flow rate of the incoming air to 3m through the flowmeter 3 / h. Weigh 300g of low hydrated magnesium chloride solid particles containing 2 crystal waters. When the set temperature is reached, start feeding in batches, adding 100g of solid material every 5 minutes. The solid material undergoes fluidized pyrolysis reaction under the set...

example 3

[0085] Example 3: Preparation of magnesium oxide by fluidized pyrolysis at 600°C

[0086] The preparation technology of low hydrate magnesium chloride solid particle material is identical with example 1.

[0087] Turn on the power of the air preheater and the electric heating furnace, control the air outlet temperature of the air preheater to 350°C, and control the electric heating furnace so that the temperature in the fluidized bed pyrolysis furnace is 600±10°C. The fluidized bed pyrolysis furnace is made of quartz glass, the inner diameter of the reactor is 40mm, and the height is 1.2m. Open the compressed air source, and control the volume flow rate of the incoming air to 3m through the flowmeter 3 / h. Weigh 300g of low hydrated magnesium chloride solid particles containing 2 crystal waters. When the set temperature is reached, start feeding in batches, adding 100g of solid material every 5 minutes. The solid material undergoes fluidized pyrolysis reaction under the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com