Automatic logistics production line for lengthening and prefabricating of two-in-one pipeline

A production line and prefabricated technology, applied in the direction of rollers, conveyor objects, conveyors, etc., can solve the problems of pairing, low welding efficiency, high labor intensity of operation, etc., achieve similar production rhythms, reduce labor intensity, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

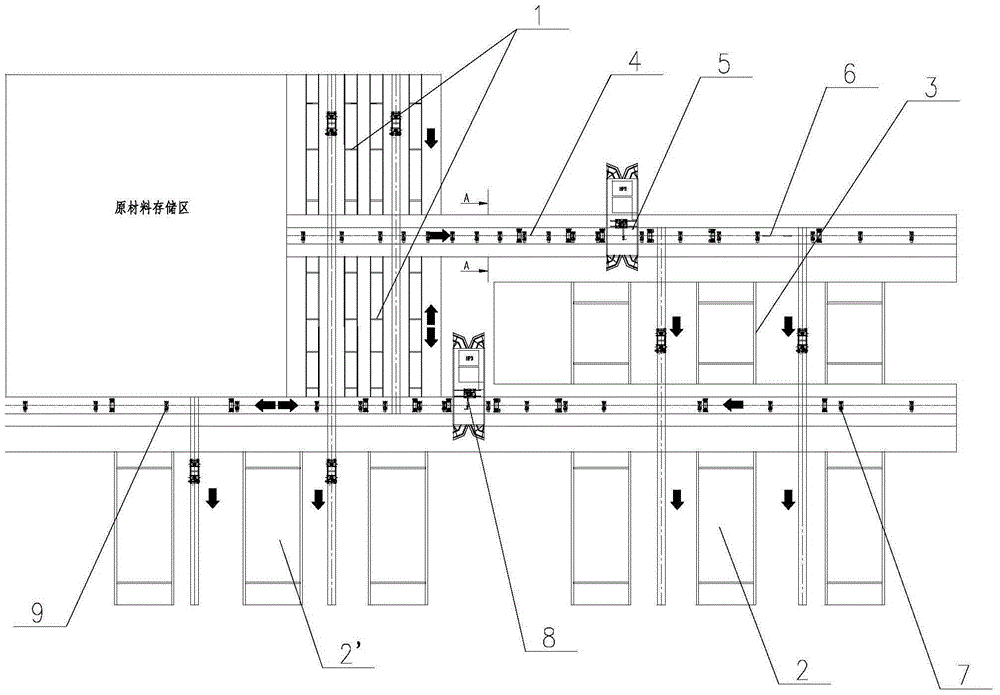

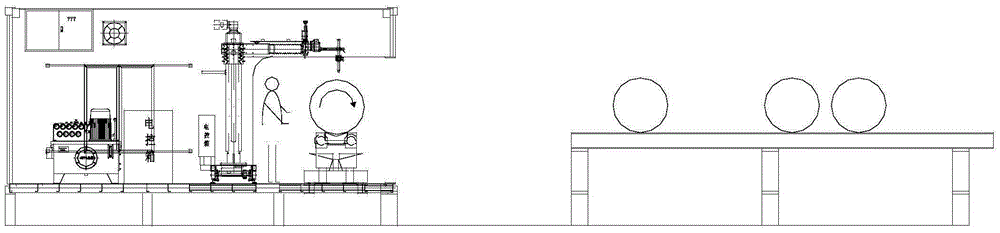

[0015] The two-connected-one-pipeline-connected prefabricated automated logistics production line provided in this embodiment has a structure such as figure 1 As shown, it includes two raw material rack storage areas 1, two finished product rack storage areas 2, 2', two butt welding station areas and a buffer rack storage area 3 connected by transmission rollers; two The first transmission roller table 4 is arranged between the raw material rack storage area 1, and is connected with the first butt welding station area 5 through the first transmission roller table 4, and the discharge port of the first butt welding station area 5 passes through the second The transmission roller table 6 is connected with the buffer rack storage area 3, and the discharge port on the other side of the buffer rack storage area 3 is connected with the first finished product rack storage area 2, and the first finished product rack storage area 2 is stored with the buffer rack storage area. There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com