Waste food treatment device and waste food treatment method

A waste food and processing method technology, which is applied in waste food processors, waste food processors and corresponding waste food processing fields, can solve the problems of easy combustion, potential safety hazards, poor adjustability, etc., and achieve the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

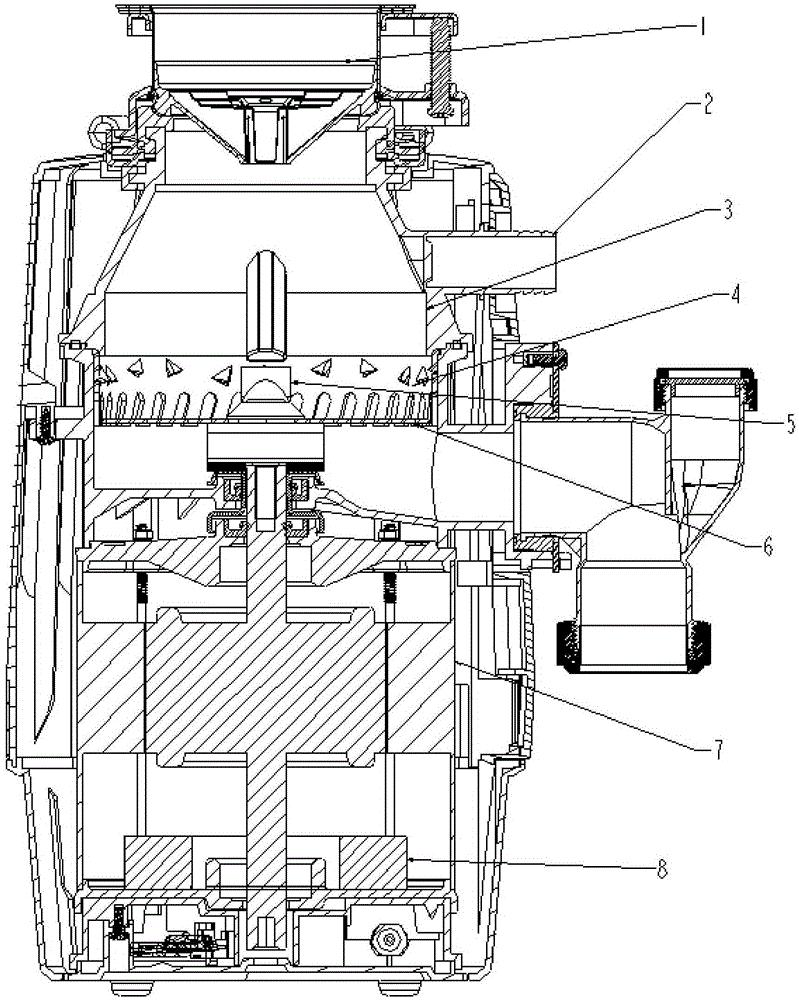

[0032] Such as figure 1 As shown, the waste food processor according to the embodiment of the present invention includes: a feed inlet 1 , a grinding chamber 3 , a grinding ring 4 , a grinding disc 6 , a motor 7 , and an electronic centrifugal switch 8 . Preferably, the grinding chamber 3 can also be provided with a side inlet, which is used to connect, for example, the drain of the dishwasher, that is, the dishwasher interface 2, so that the remaining waste food in the dishwasher can also be directly put into the waste food in the milling chamber of the processor.

[0033] In the embodiment of the present invention, the grinding ring 4 and the grinding disc 6 constitute a grinding device and are located in the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com