Narrow band-gap carbon nitride visible light photocatalyst and preparation method thereof

A technology of gap carbon nitride and catalyst, which is applied in the field of narrow band gap carbon nitride catalyst and its preparation, which can solve the problems of long reaction time and achieve the effects of low reaction temperature, convenient separation and treatment, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

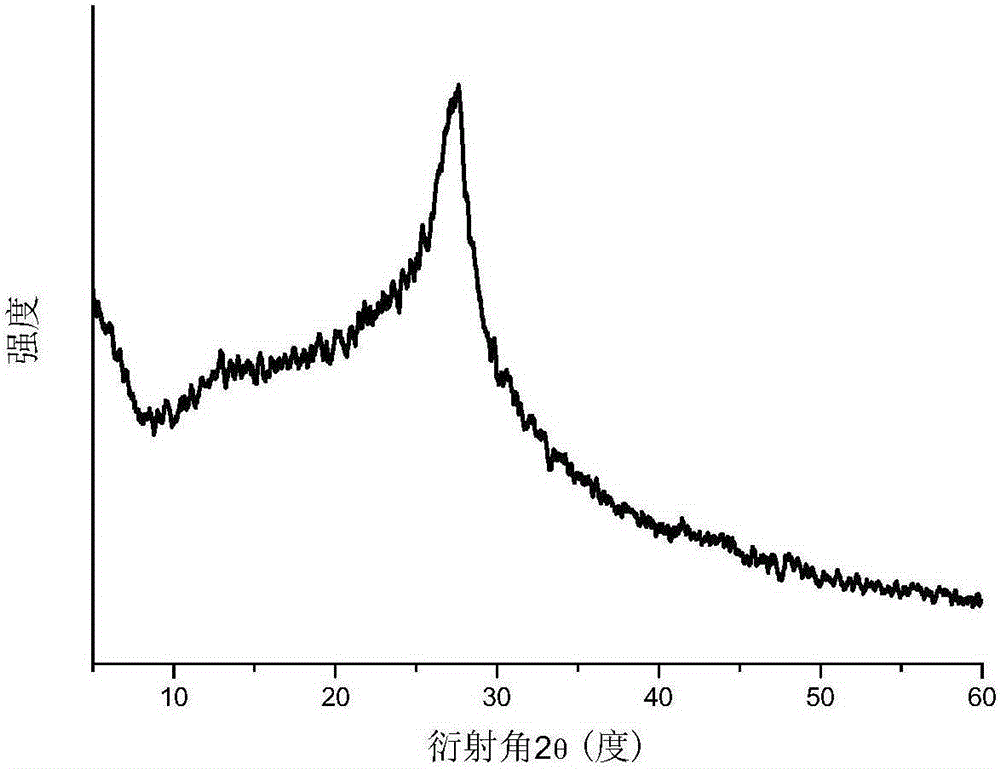

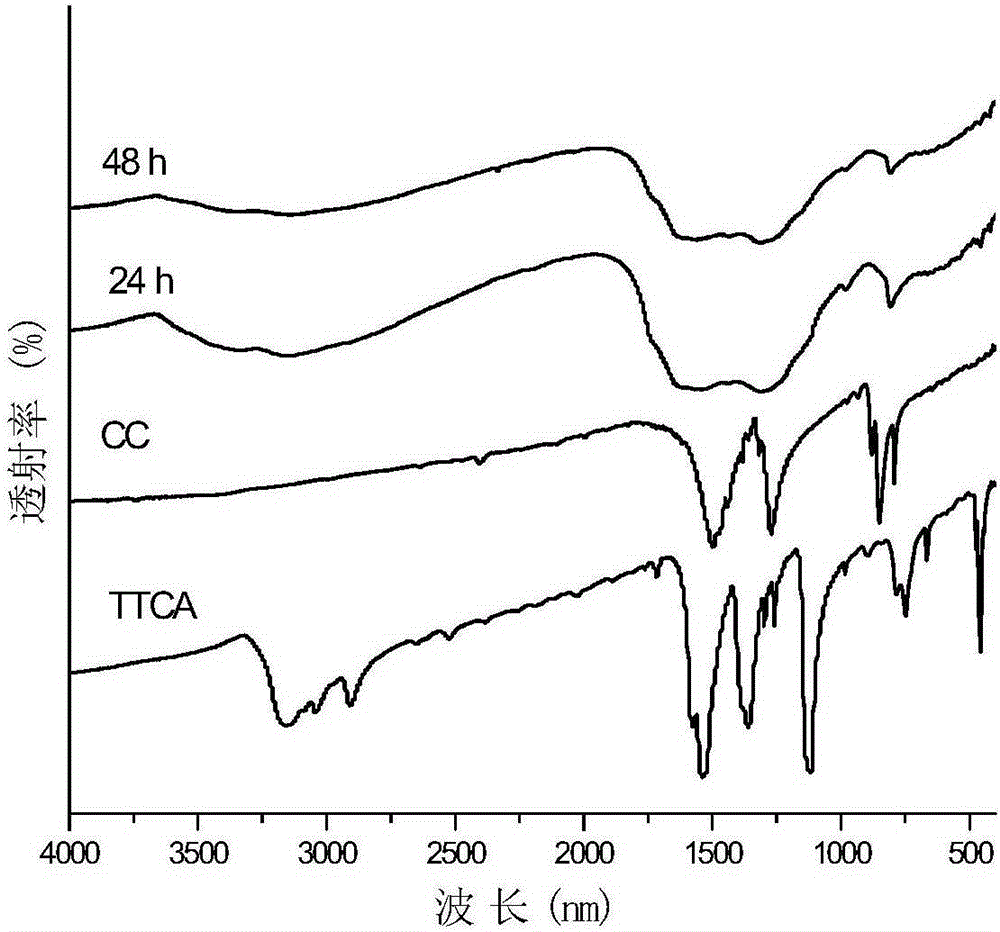

[0033] Disperse cyanuric chloride and thiocyanic acid at a molar ratio of 1:1 in acetonitrile and stir at room temperature for 12 hours. The mixed solution was transferred to a hydrothermal reaction kettle and heat-treated at a constant temperature of 180 degrees for 24 hours. Cool naturally to room temperature, separate and wash the solid product, and prepare graphite phase carbon nitride with a narrow band gap.

Embodiment 2

[0035] Disperse cyanuric chloride and thiocyanic acid at a molar ratio of 1:1 in acetonitrile and stir at room temperature for 12 hours. The mixed solution was transferred to a hydrothermal reactor and heat-treated at a constant temperature of 180 degrees for 48 hours. Cool naturally to room temperature, separate and wash the solid product, and prepare graphite phase carbon nitride with a narrow band gap.

Embodiment 3

[0037] Disperse cyanuric chloride and thiocyanic acid at a molar ratio of 5:1 in acetonitrile and stir at room temperature for 12 hours. The mixed solution was transferred to a hydrothermal reaction kettle, and heat treated at a constant temperature of 200 degrees for 72 hours. Cool naturally to room temperature, separate and wash the solid product, and prepare graphite phase carbon nitride with a narrow band gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com