Sodion secondary battery negative electrode material and preparing method and application thereof

A technology of secondary battery and negative electrode material, applied in the field of materials, can solve the problems of restricting the large-scale application of hard carbon materials, complicated preparation process of hard carbon materials, and high price of hard carbon, achieving high production efficiency, simple preparation method and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

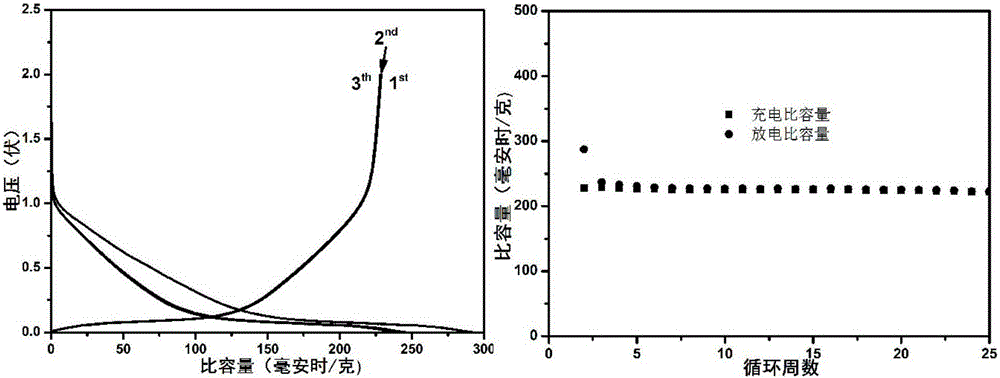

[0058] Embodiment 1 of the present invention provides a negative electrode material for a sodium ion secondary battery. The material is an amorphous carbon material, and coal and hard carbon precursors are used as raw materials. After adding a solvent, they are mechanically mixed, dried, and then passed through an exchange process under an inert atmosphere. It is prepared by linking, solidifying and cracking.

[0059] Coal and hard carbon precursors are mixed mechanically after adding a solvent at a mass ratio of 1:(0-0.99) to obtain a slurry; then dry the obtained slurry; perform crosslinking, curing, and cracking reactions under an inert atmosphere, Finally, the required materials are obtained. It should be noted that the 1:0 situation does not exist at this time, that is, the hard carbon precursor must exist at this time.

[0060] Among them, the solvent can be selected from one or any mixture of water, ethanol, isopropanol, acetone and dimethylformamide; the coal can be s...

Embodiment 2

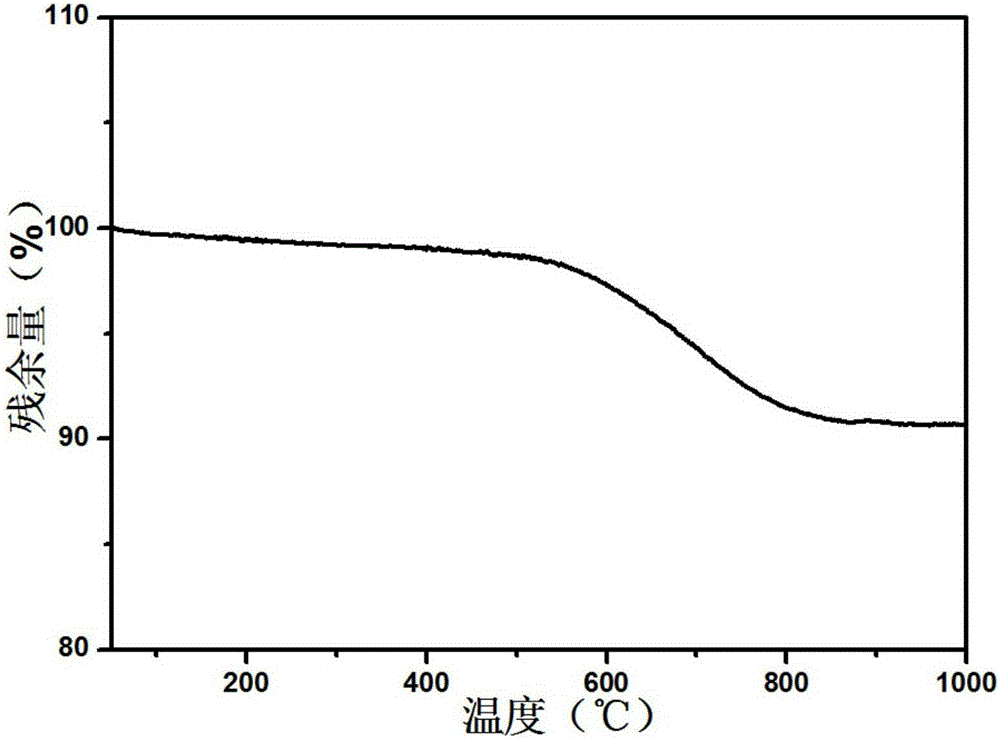

[0065] Embodiment 2 of the present invention provides a negative electrode material for a sodium ion secondary battery, which is an amorphous carbon material prepared by cracking coal as a raw material under an inert atmosphere.

[0066] Among them, the coal can be selected from one or any mixture of anthracite, bituminous coal and lignite.

[0067] Optionally, gas containing hydrocarbons can also be added during the reaction process for surface coating, so that the surface has a coating layer, preferably natural gas, methane, ethane, toluene, ethylene, acetylene, propyne and the like.

[0068] Wherein, the above-mentioned materials are granular, and the average particle size of the particles is 1-50 μm; d 002 Value between 0.35-0.42nm, L c Value between 1-4nm, L a The value is between 3-5nm.

[0069] The sodium ion secondary battery negative electrode material provided in this example is prepared from coal, which can not only increase the yield of amorphous carbon, but als...

Embodiment 3

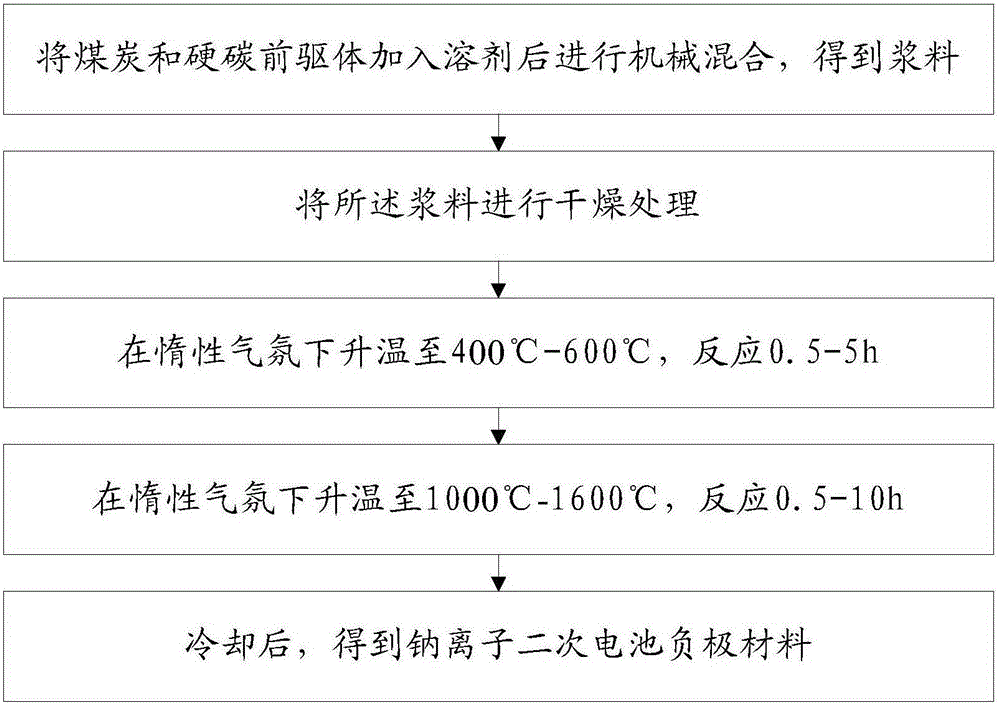

[0071] This embodiment provides a kind of preparation method of sodium ion secondary battery negative electrode material, and its steps are as follows figure 2 shown, including:

[0072] (1) Add coal and hard carbon precursors to a solvent and then mechanically mix to obtain a slurry;

[0073] Specifically, the coal and the hard carbon precursor are added into a solvent at a mass ratio of 1: (0-0.99) and then mechanically mixed to obtain a uniform slurry. What needs to be explained is that the 1:0 situation does not exist at this time, that is, the hard carbon precursor must exist at this time. Among them, the solvent can be selected from one or any mixture of water, ethanol, isopropanol, acetone and dimethylformamide; the coal can be selected from one or any mixture of anthracite, bituminous coal and lignite; The carbon precursor can be selected from one or any mixture of glucose, sucrose, lignin, cellulose, starch, phenolic resin, polyacrylonitrile and epoxy resin;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com