Manufacturing method of cable having waterproof outer sheath structure

A production method and cable technology, applied in the direction of insulating conductors/cables, etc., can solve the problems of difficult waterproof sealing of connecting lines, equipment damage, electric shock safety, etc., and achieve the effect of good practical value, easy production, and preventing glue from falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

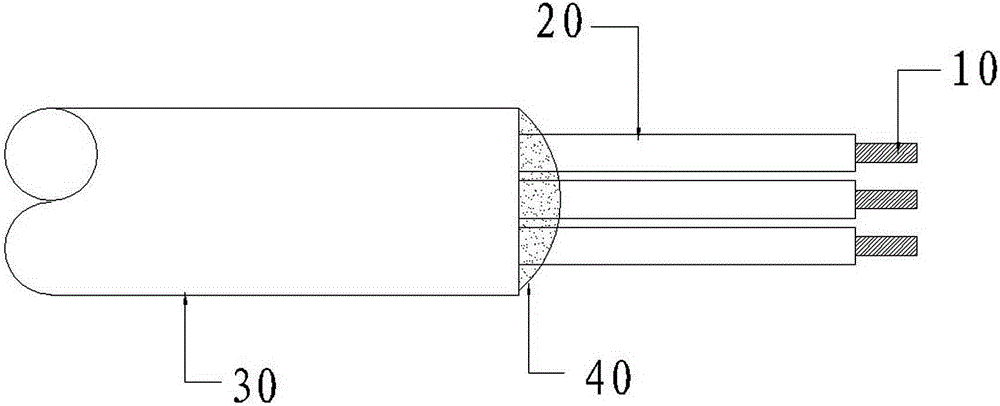

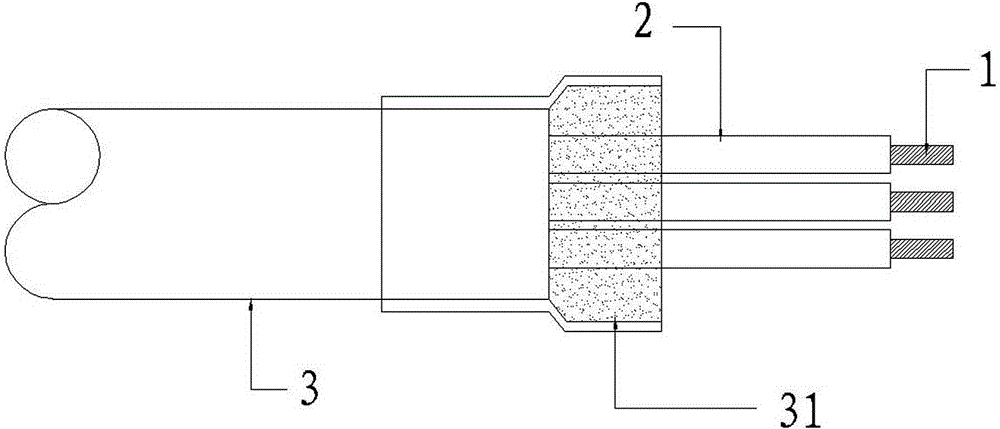

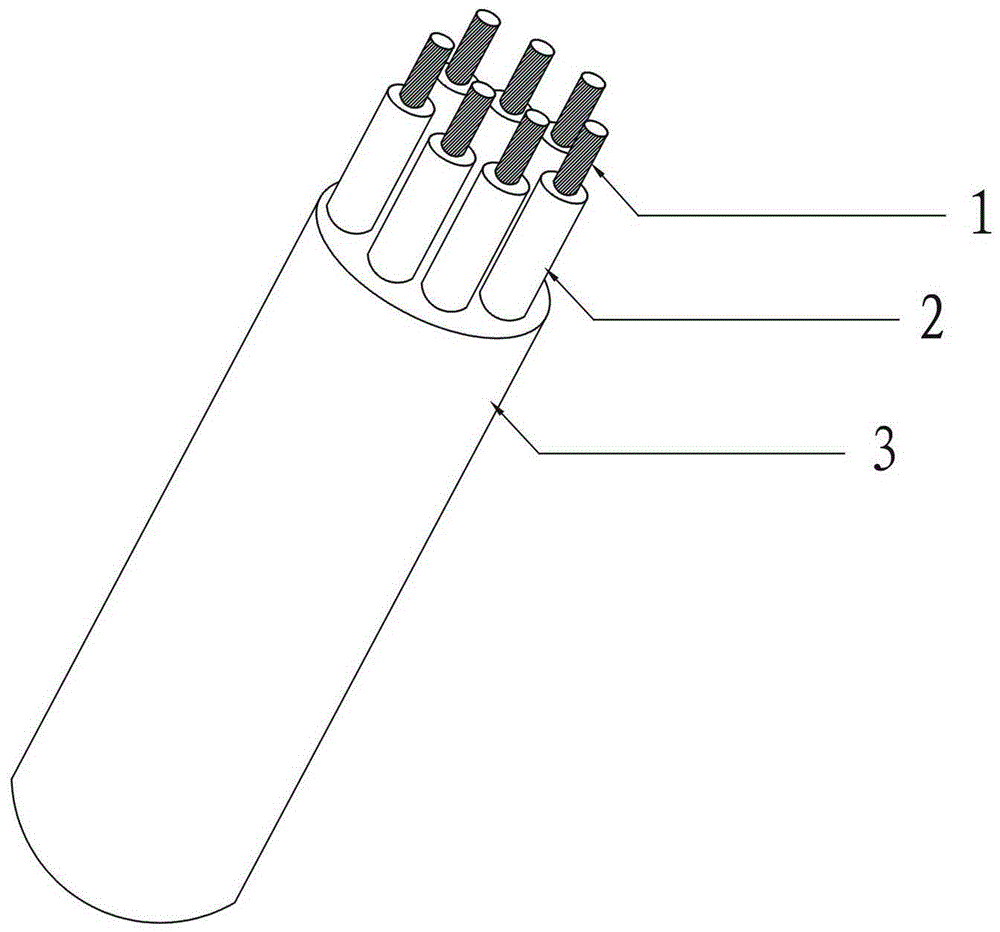

[0021] A kind of manufacture method of the cable with waterproof coating structure, see figure 2 and image 3 , the cable includes a conductor 1, a core wire 2 wrapping the conductor 1, and a waterproof outer layer 3 after the wrapping core wire is twisted into a cable, which includes the following steps:

[0022] Step 1: If figure 2 As shown, the cable is peeled at the waterproof cut, and the waterproof outer layer 3 is peeled off to expose the insulated core wire 2 inside, and the insulated core wire cannot be damaged when peeling;

[0023] Step 2: Put a heat-shrinkable tube on the waterproof cutout of the cable, place the heat-shrinkable tube on the waterproof cutout of the cable and bake it, so that the heat-shrinkable tube is heat-shrunk into a trumpet shape, forming a Horn opening 31;

[0024] Step 3: Carry out glue filling and sealing through the opening 31 of the horn, and the glue must fill the mouth of the horn. The amount of glue filling should not overflow or...

Embodiment 2

[0026] In order to prevent the inner core wire from being damaged when heating the cable, in this embodiment, refer to Figure 4 , before the heat-shrinkable tube is put on, a layer of detachable protective layer 4 is firstly put on the waterproof cut of the cable. Specifically, step 2 in the embodiment can be replaced by the following process: First, a layer of detachable protective layer 4 is sheathed at the waterproof incision of the cable, and the protective layer 4 is sheathed between the core wires at the waterproof incision. Then, the heat-shrinkable tube is put through the waterproof cut of the cable, and the heat-shrinkable tube is heat-baked to make it heat-shrink to form a horn opening 31; then the protective layer 4 is removed. Wherein, the protective layer must not shrink when exposed to heat, or be higher than the melting point of the heat-shrinkable tube, and the protective layer will not be affected when the heat-shrinkable tube shrinks. At the same time, the ...

Embodiment 3

[0029] For convenience, see Figure 5 , the cable also includes a detachable clamping part 5, the clamping part 5 has a tubular sleeve 51, the end of the tubular sleeve 51 has a trumpet-shaped opening 52; After the waterproof incision, the clamping part 5 is sleeved outside the heat-shrinkable tube, and then the heat-shrinkable tube is heat-baked so that it is heat-shrunk to form a horn opening, which is connected to the end of the tubular sleeve 51 The trumpet-shaped opening 52 coincides; wherein, the diameter of the tubular sleeve 51 of the clamping part 5 is slightly larger than the diameter of the heat-shrinkable tube, so that the clamping part is sleeved outside the heat-shrinkable tube and will not fall off. In this implementation example, before the heat-shrinkable tube is put on, a layer of detachable protective layer 4 is firstly put on the waterproof cut of the cable.

[0030] In this way, when the heat-shrinkable tube is heat-shrunk into a trumpet shape, it coincid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com