Composite pavement structure for urban down-traversing pavement and construction method

A composite pavement and surface structure technology, applied to roads, roads, road reinforcements, etc., can solve the problems of lack of reinforced structures, noise pollution, low sound absorption coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

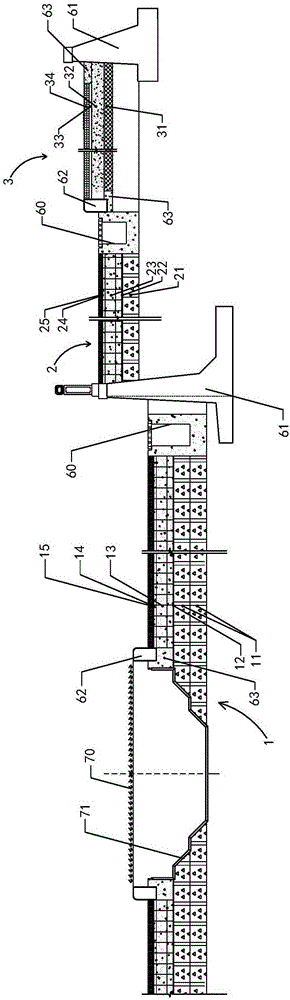

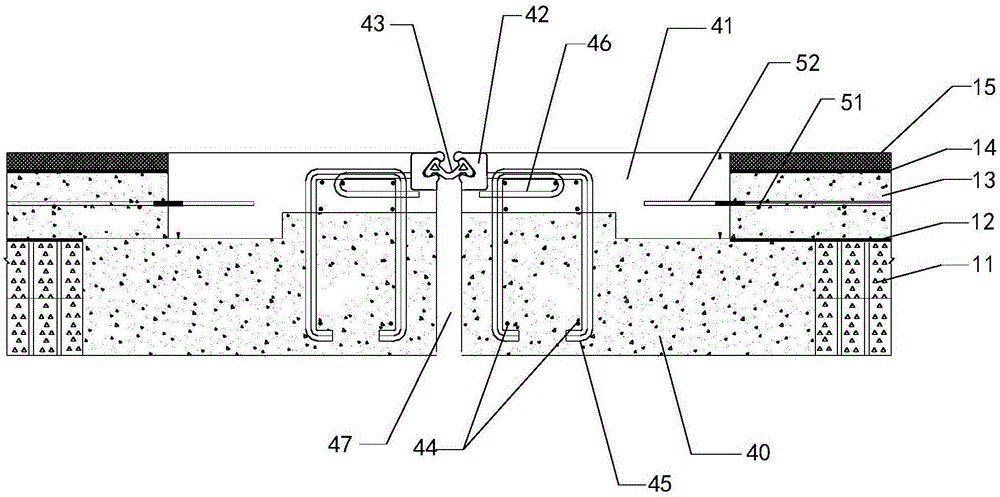

[0035] see Figure 1 to Figure 4 , a preferred embodiment of the present invention is a composite pavement structure for urban underpass roads, comprising a motor vehicle pavement structure 1, a non-motor vehicle pavement structure 2 and a sidewalk pavement structure 3 arranged side by side, wherein,

[0036] The motor vehicle pavement structure 1 consists of two layers of cement stabilized macadam layer 11, one layer of SBS modified emulsified asphalt lower seal layer 12, one layer of continuous reinforced concrete layer 13, and one layer of rubber stress absorption layer laid in sequence from the bottom layer to the top layer. 14 (AR-SAMI), and a layer of fine-grained SBS modified asphalt concrete 15 (AC-13C);

[0037] The non-motor vehicle pavement structure 2 consists of a layer of cement stabilized gravel layer 21, a layer of SBS modified emulsified asphalt lower seal layer 22, a layer of continuous reinforced concrete layer 23, and a layer of rubber stress absorbing laye...

Embodiment 2

[0051] A construction method for a composite pavement structure for urban underpass roads according to a preferred embodiment of the present invention comprises the following steps in sequence:

[0052] S1. Use open cut method or shallow burial and concealed excavation method to obtain the underpass, compact the roadbed, and make the rebound modulus of the roadbed on the motor vehicle road and non-motor vehicle road not less than 40Mpa and 35Mpa respectively, so that the roadbed in The location of sidewalks is compacted;

[0053] S2. Where the subgrade is located on the motorway, two layers of cement-stabilized macadam, one layer of SBS modified emulsified asphalt lower seal layer, one layer of continuous reinforced concrete layer, and one layer of rubber stress-absorbing layer (AR- SAMI), and a layer of fine-grained SBS modified asphalt concrete (AC-13C);

[0054] S3. Where the subgrade is located in the non-motor vehicle lane, a layer of cement-stabilized gravel, a layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Modulus of resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com