Manufacturing method of durable antistatic water-repellent fabric

A manufacturing method and antistatic technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of inability to take into account the antistatic effect and waterproof effect of fabrics, poor washing effect, etc., to improve durability and durability. The effect of washing resistance, improving adsorption capacity, and improving lasting antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

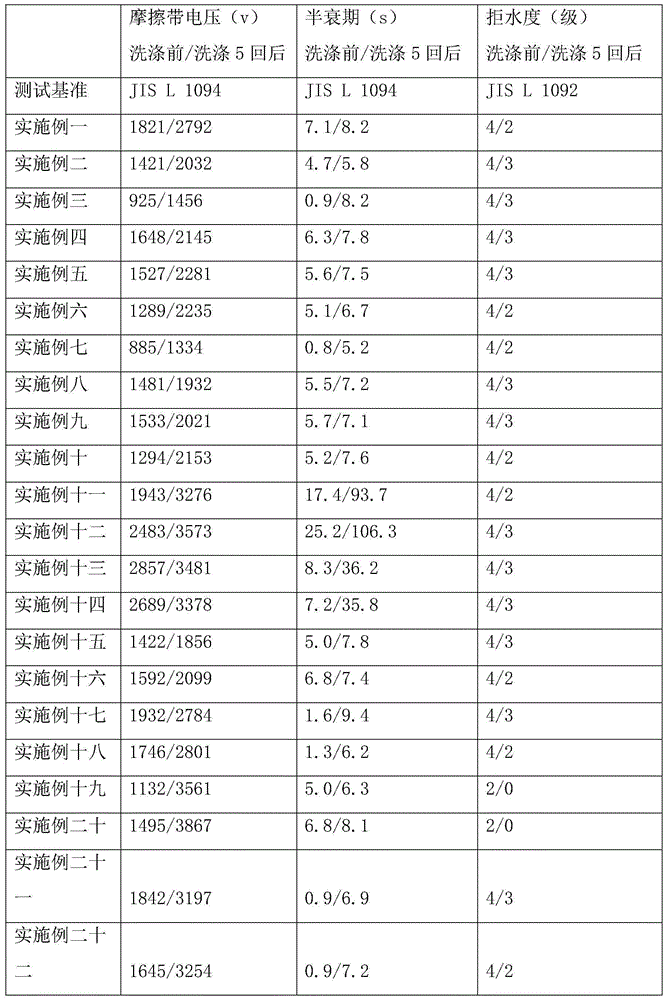

Examples

Embodiment 1

[0036] A method for manufacturing a durable antistatic water-repellent fabric, comprising the steps of:

[0037] Step 1: select the fabric woven from polyester fibers with a yarn fineness of 7D as the base fabric, and the grammage of the fabric is 17g / sqm;

[0038] Step 2: Corona treatment is performed on the fabric base cloth in Step 1, the corona current is controlled at 2A, the power is controlled at 300W, and the time is 200s.

[0039] Step 3: Antistatic treatment is carried out on the finishing liquid after antistatic treatment, the pH is adjusted to between 5 and 5 with citric acid, 2 dips and 1 rolling are used, the liquid volume is controlled at 40%, and the roll pressure is 0.3mpa; then non-contact Infrared pre-drying treatment, the drying time is 15s, the drying temperature is 80°C, and then it is dried by direct contact drum, the drying temperature is 80°C, the drying time is 45s, and a continuous anti-corrosion layer is formed on the fiber surface after cooling tre...

Embodiment 2

[0042] A method for manufacturing a durable antistatic water-repellent fabric, comprising the steps of:

[0043] Step 1: select the fabric woven with nylon fiber with a yarn fineness of 10D as the base fabric, and the grammage of the fabric is 22g / sqm;

[0044] Step 2: Corona treatment is performed on the fabric base cloth in Step 1, the corona current is controlled at 2A, the power is controlled at 300W, and the time is 200s.

[0045] Step 3: Antistatic treatment is carried out on the finishing liquid after antistatic treatment, the pH is adjusted to between 5 and 5 with citric acid, 2 dips and 1 rolling are used, the liquid volume is controlled at 40%, and the roll pressure is 0.3mpa; then non-contact Infrared pre-drying treatment, the drying time is 15s, the drying temperature is 80°C, and then it is dried by direct contact drum, the drying temperature is 80°C, the drying time is 45s, and a continuous anti-corrosion layer is formed on the fiber surface after cooling treatme...

Embodiment 3

[0048] A method for manufacturing a durable antistatic water-repellent fabric, comprising the steps of:

[0049] Step 1: select the fabric woven from polyester fibers with a yarn fineness of 20D as the base fabric, and the grammage of the fabric is 42g / sqm;

[0050] Step 2: Corona treatment is performed on the fabric base cloth in Step 1, the corona current is controlled at 2A, the power is controlled at 300W, and the time is 200s.

[0051] Step 3: Antistatic treatment is carried out on the finishing liquid after antistatic treatment, the pH is adjusted to between 5 and 5 with citric acid, 2 dips and 1 rolling are used, the liquid volume is controlled at 40%, and the roll pressure is 0.3mpa; then non-contact Infrared pre-drying treatment, the drying time is 15s, the drying temperature is 80°C, and then it is dried by direct contact drum, the drying temperature is 80°C, the drying time is 45s, and a continuous anti-corrosion layer is formed on the fiber surface after cooling tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com