Method for preparing polyformaldehyde nascent fibers

A nascent fiber and polyoxymethylene technology, which is applied to complete sets of equipment for producing artificial threads, chemical characteristics of fibers, melt spinning methods, etc., can solve the problems of complex production industrial processes, high industrial production costs, and large production area. Good spinnability, reduction of crystallization rate, effect of inhibiting crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

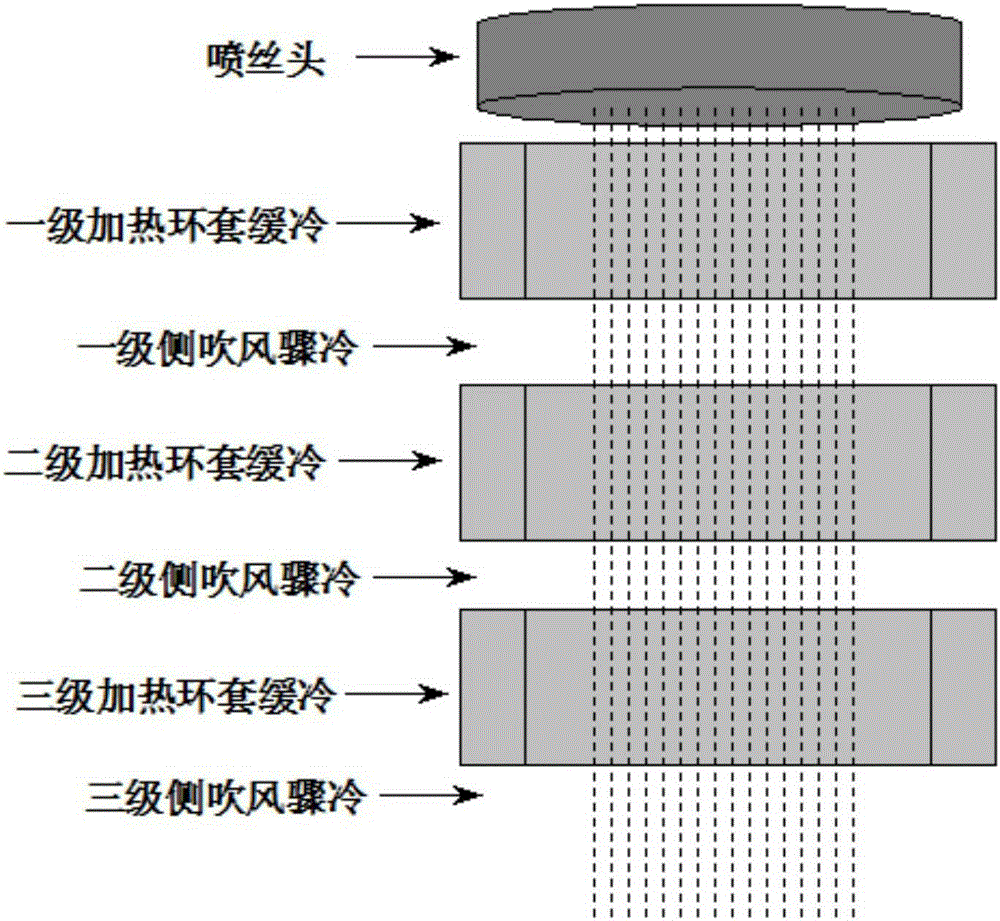

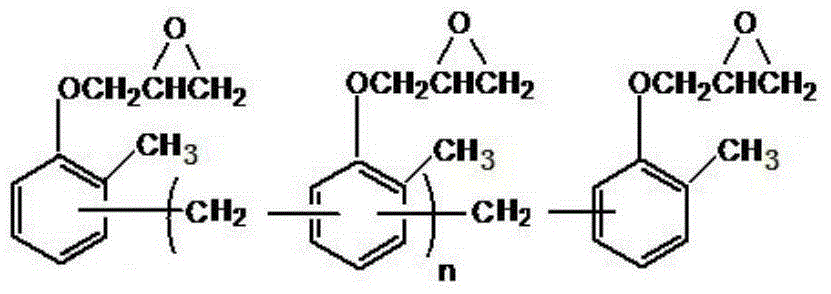

[0025]The polyoxymethylene resin has a melt index of 11 g / 10 min, and the mass percentage of o-cresol novolak epoxy resin is 1.0 wt.%, and it is dried at 90° C. for 6 hours. The resin pellets are melted and heated by the screw extruder, metered and distributed by the metering pump, and then sprayed out through the spinneret. The temperature of each section of the screw melt spinning: 60°C for the first zone, 210°C for the second zone, 200°C for the third zone, and 230°C for the head. °C, assembly 235 °C. After the melt stream is sprayed from the spinneret, it passes through the slow cooling-quick cooling device, and the total length of the slow cooling-quick cooling device is 1 / 3 of the total distance between the spinneret and the oiling device, and the first stage of slow cooling and heating The distance between the upper surface of the sleeve and the lower surface of the spinneret is 0mm, the length of the heating jacket is 200mm, and the heating temperature is 235°C; The t...

Embodiment 2

[0027] The polyoxymethylene resin has a melt index of 11 g / 10 min, and the mass percentage of o-cresol novolak epoxy resin is 1.0 wt.%, and it is dried at 90° C. for 6 hours. The resin pellets are melted and heated by the screw extruder, metered and distributed by the metering pump, and then sprayed out through the spinneret. The temperature of each section of the screw melt spinning: 60°C for the first zone, 210°C for the second zone, 200°C for the third zone, and 230°C for the head. °C, assembly 235 °C. After the melt stream is sprayed from the spinneret, it passes through the slow cooling-quick cooling device, and the total length of the slow cooling-quick cooling device is 1 / 3 of the total distance between the spinneret and the oiling device, and the first stage of slow cooling and heating The distance between the upper surface of the sleeve and the lower surface of the spinneret is 0mm, the length of the heating jacket is 200mm, and the heating temperature is 235°C; The ...

Embodiment 3

[0029] The polyoxymethylene resin has a melt index of 11 g / 10 min, and the mass percentage of o-cresol novolak epoxy resin is 1.0 wt.%, and it is dried at 90° C. for 6 hours. The resin pellets are melted and heated by the screw extruder, metered and distributed by the metering pump, and then sprayed out through the spinneret. The temperature of each section of the screw melt spinning: 60°C for the first zone, 210°C for the second zone, 200°C for the third zone, and 210°C for the head. ℃, module 220℃. After the melt stream is sprayed from the spinneret, it passes through the slow cooling-quick cooling device, and the total length of the slow cooling-quick cooling device is 1 / 3 of the total distance between the spinneret and the oiling device, and the first stage of slow cooling and heating The distance between the upper surface of the jacket and the lower surface of the spinneret is 0mm, the length of the heating jacket is 200mm, and the heating temperature is 220°C; The tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com