System and method for utilizing biogas slurry and straw hydrolysate to prepare amino acid and separate CO2

A hydrolyzate and amino acid technology, applied in the direction of microorganism-based methods, sterilization methods, biochemical equipment and methods, etc., can solve problems such as difficult to handle waste, environmental secondary pollution, high ammonia nitrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

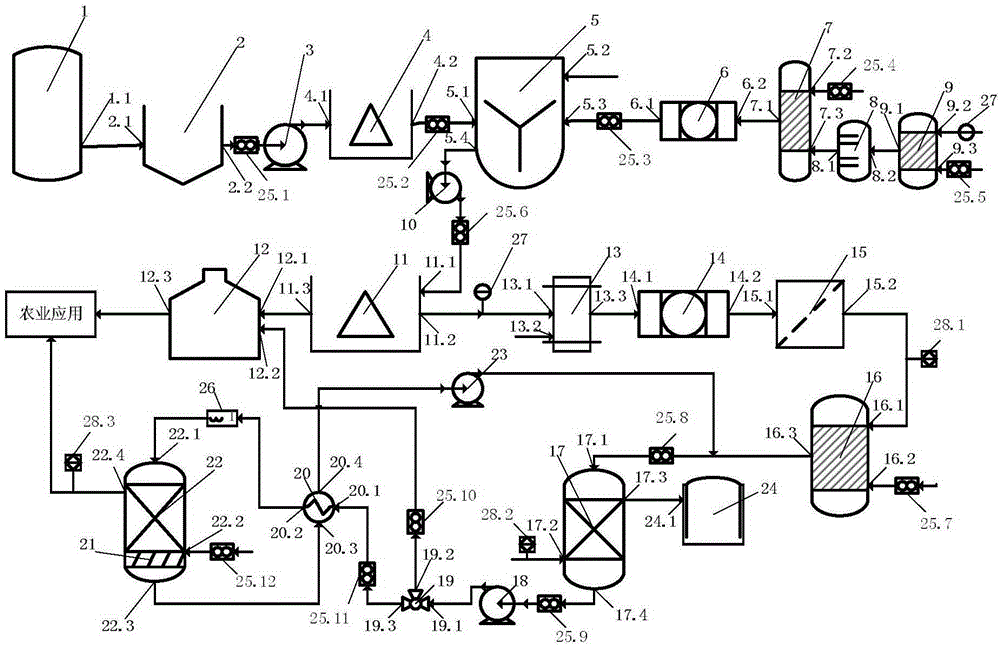

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0034] Such as figure 1 The shown biogas slurry and straw hydrolyzate for the preparation of amino acids and the separation of CO 2 The system includes biogas engineering fermentation equipment 1, biogas slurry precipitation equipment 2, biogas slurry centrifugal equipment 4, stirring fermentation equipment 5, first filter 6, straw saccharification reaction equipment 7, straw washing equipment 8, straw pretreatment reactor 9 , suspended fermentation liquid centrifugal equipment 11, biogas slurry liquid storage tank 12, yeast hydrolysis reactor 13, second filter 14, yeast hydrolyzate concentration equipment 15, amino acid salt reactor 16, CO 2 Absorption equipment 17, three-way valve 19, rich liquid desorption equipment 22, purified gas storage tank 24, it also includes the first delivery pump 3, the second delivery pump 10, the third delivery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com