High-dissolvability acid yellow dye and preparation method thereof

A high-solubility, acid yellow technology, applied in the direction of organic dyes, azo dyes, monoazo dyes, etc., can solve the problem of solubility difference in water, etc., and achieve the effect of bright color and excellent solubility performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

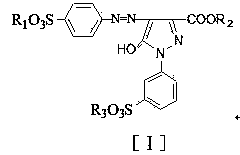

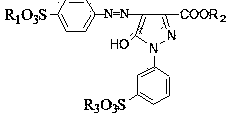

Method used

Image

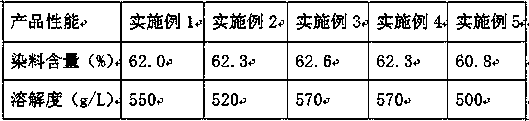

Examples

Embodiment 1

[0030] Add 380kg of water to the diazo kettle, start stirring, add 451kg of zebane sulfanilic acid, then add 550kg of 25% sulfuric acid solution, then add 500kg of ice, and add 182kg of zebra sodium nitrite dropwise under slow liquid 30% aqueous solution, control the temperature T<20 °C, after the addition, the Congo red test paper and the starch-potassium iodide test paper are blue; continue to stir for 30 minutes, and remove excess sodium nitrite with a small amount of sulfamic acid.

[0031] The prepared diazonium m-aminobenzenesulfonic acid salt was put into the condensation kettle, and 490kg of dimethyl 2-acetylsuccinate melted liquid was metered and pumped, and about 350kg of ammonium bicarbonate was slowly added, and the temperature was controlled at 15-25 ℃ and PH<5.2 until the diazonium salt disappears.

[0032] Add 380kg of water to the diazo kettle, start stirring, add 451kg of zebra-sulfanilic acid, then add 570kg of 98% sulfuric acid, then add 500kg of ice, add 18...

Embodiment 2

[0036] Replace "the ammonium bicarbonate of about 350kg slowly" in "slowly adding about 370kg of sodium bicarbonate" in embodiment 1, and all the other are the same as embodiment 1 to get 2045kg of finished product.

Embodiment 3

[0038] Replace the "slowly sprinkle about 340kg of soda ash into the condensation liquid to adjust the pH to 7.8" in Example 1 with "slowly sprinkle about 330kg of ammonium carbonate into the condensation liquid, adjust the pH to 7.5", and implement the rest in the same way Example 1, get finished product 2052kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com