Precision casting wax, preparation method therefor and applications

A precision casting and precision manufacturing technology, applied in the field of precision casting wax and its preparation, can solve the problems of different shrinkage rates of wax blocks, uneven heat conduction, remelting, etc., and achieve improved remelting and wire drawing phenomena, uniform internal components, and shrinkage rate uniform effect

Active Publication Date: 2015-12-23

上海沪亮生物医药科技有限公司

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, in CAD precision machining, unmodified PE wax blocks are prone to remelting and wire drawing in small size ranges (≤100 microns) due to molecular internal stress and heat accumulation effect during machining, which seriously affects Therefore, how to improve the CAD processing performance of casting wax based on PE wax has become a major problem in the industry

[0005] In addition, due to the large volume of the casting wax block, uneven heat conduction often occurs during the molding cooling process, resulting in the cooling rate of the outer layer being faster than that of the inner layer. The wax melt located in the inner layer also has a certain The fluidity of the prepared wax block will produce uneven density, which will lead to different shrinkage rates of various parts of the wax block in severe cases, which will eventually affect product quality.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~4

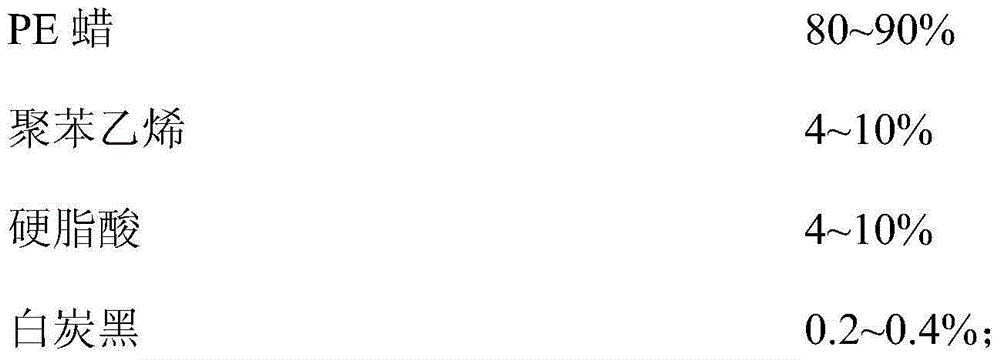

[0040] Prepare investment casting wax according to the process described in the examples, and the specific formula ratio is shown in Table 1:

[0041] The investment casting wax formula composition that table 1 embodiment 1~4 provides

[0042] Raw materials (wt%)

[0043] figure 1 The disc-shaped casting wax block prepared for Example 1 of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to precision casting wax. The precision casting wax comprises the following ingredients, by weight, 80-90% of PE wax, 4-10% of polystyrene, 4-10% of eleaostearic acid and 0.2-0.4% of white carbon black, and the mass percent sum of the precision casting wax is 100wt%. During the CAD precise processing of the precision casting wax, re-fusion and wire drawing phenomena in a small-sized scope are reduced obviously, and the effects of the precision casting wax with PE wax as base wax and used for CAD precise processing are improved obviously. The internal components of the precision casting wax are uniform, the shrinkage of each part is uniform, and the wax block quality is raised.

Description

technical field [0001] The invention belongs to the technical field of precision casting, and relates to a precision casting wax and its preparation method and application. Background technique [0002] With the rapid development of material science, the application of CAD technology in polymer composites has attracted more and more attention. As a typical polymer composite matrix, PE wax can replace metal, wood, and thermosetting plastics as three-dimensional molds used in the production of handicrafts, human tissue models, dental models, and daily necessities. [0003] The application of investment casting technology can quickly mold PE wax into the required basic shape, and then obtain the product model or mold through CAD drawing and mechanical engraving. Investment casting works by heating the polymer above its melting point to form a flow state similar to that of liquid metal, and then cooling it in the desired mold to obtain a casting wax block. The casting wax bloc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/06C08L25/06C08K5/09C08K3/36B22C7/02

Inventor 李晓强

Owner 上海沪亮生物医药科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com