Polymer-based insulating and heat conducting composite material with efficient heat conductivity and excellent mechanical properties

An insulating and thermally conductive, polymer-based technology, used in household appliances, other household appliances, applications, etc., can solve the problems of unreachable, high thermal conductivity of conductive and thermally conductive fillers, loss of filling efficiency, etc., to increase the filling amount. , The effect of improving the conductivity threshold and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Choose high-density polyethylene (5000s, produced by Yanshan Petrochemical Co., Ltd.), with a melt index of 1g / 10min (190°C, 2.16kg); graphite (325 mesh, Qingdao Xingyuan Graphite Milk Co., Ltd.), with a particle size of about 44 μm. High-density polyethylene and graphite are mixed in a high-speed stirrer at a weight ratio of 67:33, and then dried in a vacuum oven at 80°C for 12 hours after dispersion.

[0030] (2) Use the twin-screw extruder to mix and granulate the dried mixture to form a granular premix with a diameter of about 1mm and a length of about 3mm. The twin-screw feeding port, conveying section, melting section, uniform The temperatures of the chemical section and the die are 155°C, 195°C, 195°C, 195°C, and 190°C, respectively. The prepared granular premix was placed in a vacuum oven at 80°C and dried for 12 hours.

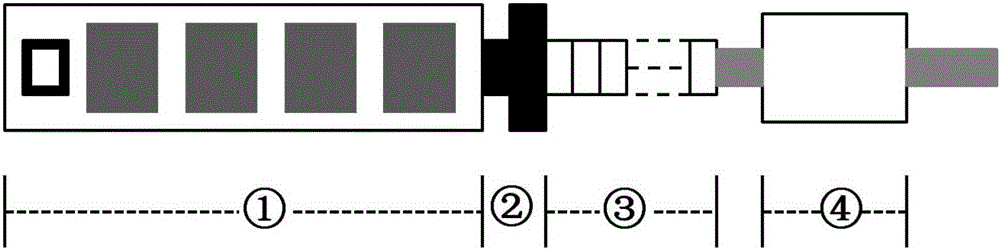

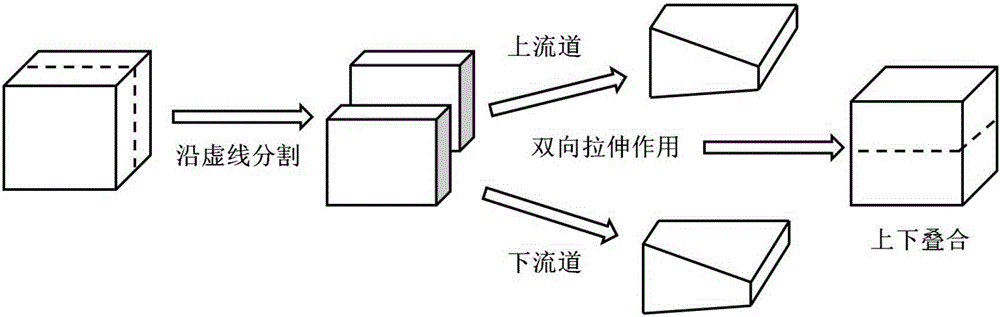

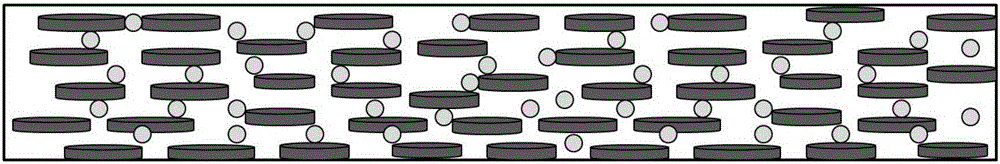

[0031] (3) Put the dried granular premix obtained above into the self-developed multi-stage stretching extrusion equipment (such as fi...

Embodiment 2

[0034] (1) Choose high-density polyethylene (5000s, produced by Yanshan Petrochemical Co., Ltd.), with a melt index of 1g / 10min (190°C, 2.16kg); graphite (325 mesh, Qingdao Xingyuan Graphite Milk Co., Ltd.), with a particle size of about 44 μm; silicon carbide (Qinhuangdao Yinuo High-tech Material Development Co., Ltd.), the particle size is about 2.9 μm. Among them, high-density polyethylene and graphite are mixed in a high-speed blender at a weight ratio of 67:33, and then silicon carbide accounting for 10% of the overall mass fraction is added, mixed again, dispersed, and dried in a vacuum oven at 80°C for 12 hours.

[0035] (2) Use the twin-screw extruder to mix and granulate the dried mixture to form a granular premix with a diameter of about 1mm and a length of about 3mm. The twin-screw feeding port, conveying section, melting section, uniform The temperatures of the chemical section and the die are 155°C, 195°C, 195°C, 195°C, and 190°C, respectively. The prepared granu...

Embodiment 3

[0039] (1) Choose high-density polyethylene (5000s, produced by Yanshan Petrochemical Co., Ltd.), with a melt index of 1g / 10min (190°C, 2.16kg); graphite (325 mesh, Qingdao Xingyuan Graphite Milk Co., Ltd.), with a particle size of about 44 μm; silicon carbide (Qinhuangdao Yinuo High-tech Material Development Co., Ltd.), the particle size is about 2.9 μm. Among them, high-density polyethylene and graphite are mixed in a high-speed blender at a weight ratio of 67:33, and silicon carbide accounting for 20% of the overall mass fraction is added, mixed again, dispersed, and dried in a vacuum oven at 80°C for 12 hours.

[0040] (2) Use the twin-screw extruder to mix and granulate the dried mixture to form a granular premix with a diameter of about 1mm and a length of about 3mm. The twin-screw feeding port, conveying section, melting section, uniform The temperatures of the chemical section and the die are 155°C, 195°C, 195°C, 195°C, and 190°C, respectively. The prepared granular p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com