Gold micro-nano structure array and preparation method as well as application thereof

A micro-nano structure, gold micro-nano technology, applied in the direction of micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problem of affecting the stability of SERS substrates, the easy oxidation and vulcanization of silver nanostructures, and the inability to obtain SERS substrates, etc. problems, and achieve the effects of low cost, simple preparation method, and simple and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The concrete steps of preparation are:

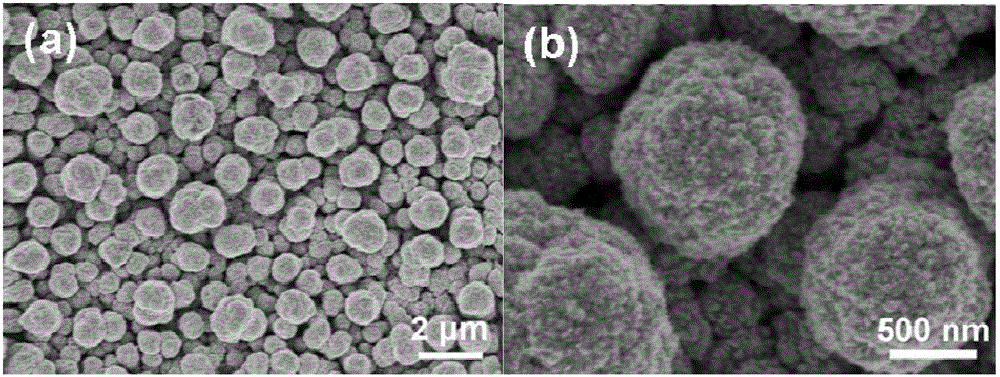

[0037] A gold film is sputtered on the substrate first; wherein, the substrate is a single crystal silicon wafer in a semiconductor, and the thickness of the gold film is 10nm. Then put the graphite as the anode and the substrate covered with the gold film as the cathode in the gold electrolyte, at 30μA / cm 2 Electrodeposition under direct current for 20h; Among them, the gold electrolyte is a mixture of 0.2g / L chloroauric acid solution and 50g / L polyvinylpyrrolidone solution, which is similar to figure 1 The shown array of gold micro-nanostructures. Afterwards, the gold micro-nanostructure array was washed once with deionized water.

Embodiment 2

[0039] The concrete steps of preparation are:

[0040] A gold film is sputtered on the substrate first; wherein, the substrate is a single crystal silicon wafer in a semiconductor, and the thickness of the gold film is 20nm. Then put the graphite as the anode and the substrate covered with the gold film as the cathode in the gold electrolyte, at 130μA / cm 2 Electrodeposition under direct current for 17h; Among them, the gold electrolyte is a mixture of 1.2g / L chloroauric acid solution and 38g / L polyvinylpyrrolidone solution, which is similar to figure 1 The shown array of gold micro-nanostructures. Afterwards, the gold micro-nanostructure array was washed twice with deionized water.

Embodiment 3

[0042] The concrete steps of preparation are:

[0043] A gold film is sputtered on the substrate first; wherein, the substrate is a single crystal silicon wafer in a semiconductor, and the thickness of the gold film is 30nm. Then put the graphite as the anode and the substrate covered with the gold film as the cathode in the gold electrolyte, at 250μA / cm 2 Electrodeposition under the DC current of 14h; Wherein, gold electrolytic solution is the mixed solution of the chloroauric acid solution of 2.5g / L and the polyvinylpyrrolidone solution of 25g / L, makes such as figure 1 The shown array of gold micro-nanostructures. Afterwards, the gold micro-nanostructure array was washed twice with deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com