A protective cover for wing fuel tank and its forming process

A technology for wing fuel tanks and flaps, which is applied in the directions of wings, aircraft parts, aircraft accessories, etc., can solve the complex structure of the inner flap and the outer flap, high manufacturing process and assembly process requirements, and incomplete elimination of risks, etc. problem, to achieve the effect of simple structure, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

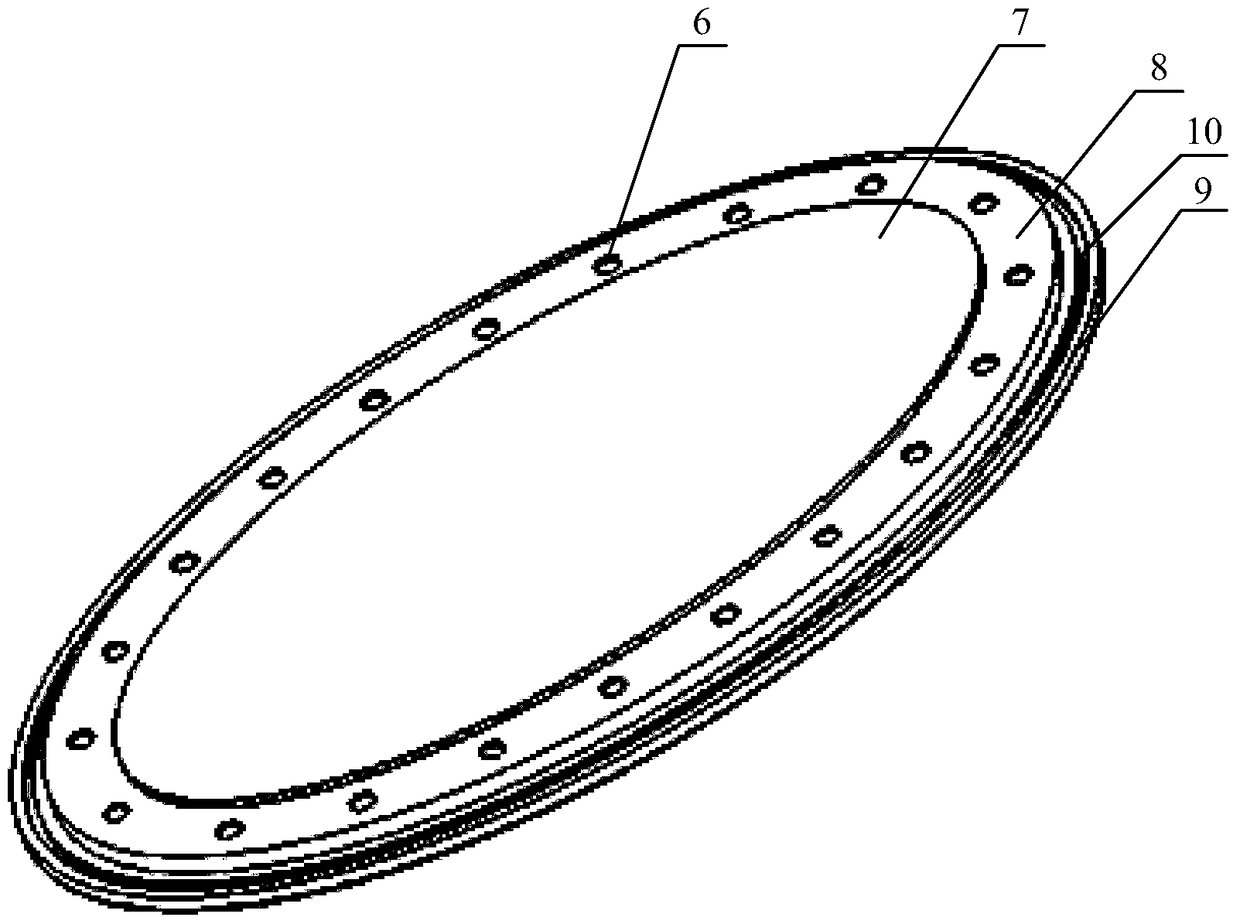

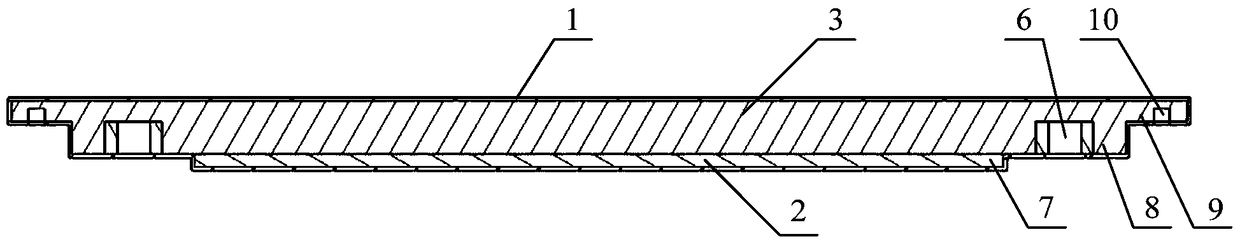

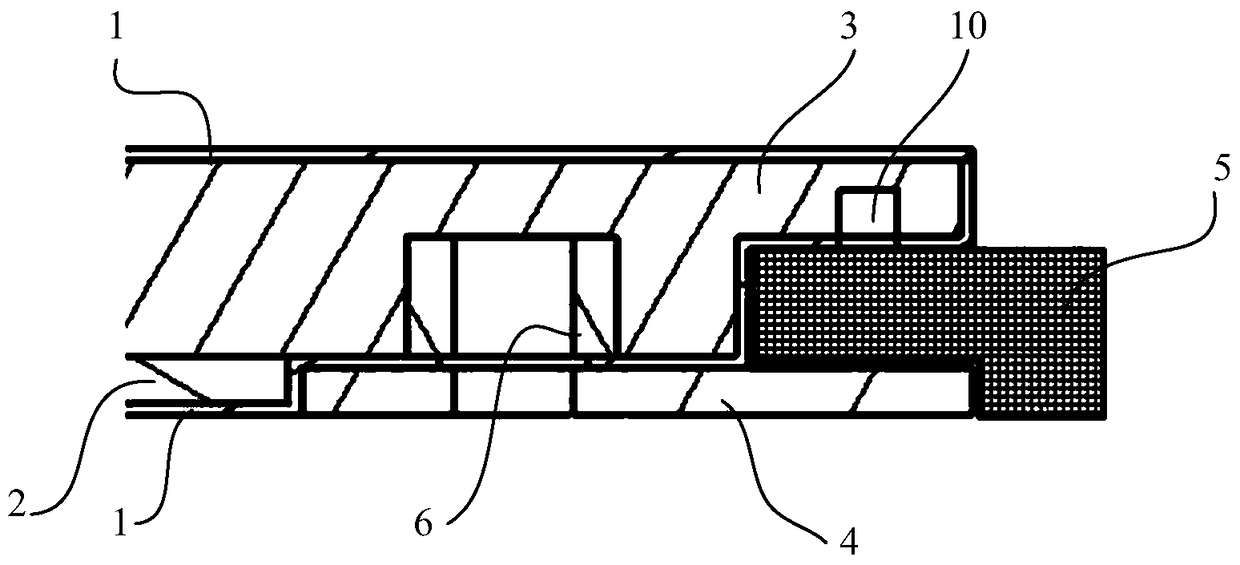

[0028] like Figure 1-3 As shown, a wing fuel tank cover includes a cover body, the cover body and the clamping pressure ring 4 clamp the skin 5, the cover body includes a protective layer 1 and a reinforcement layer 2 inside the protective layer 1, and the protective layer 1. It is used to prevent lightning and fire. Specifically, the protective layer 1 includes a carbon fiber layer and a metal mesh layer, and the metal mesh layer is coated on the carbon fiber layer, wherein the metal mesh layer is a copper mesh, and the resistivity of the copper mesh is small, and the price is moderate; The reinforcement layer 2 is made of polyethylene fiber, which is used to resist the impact of external objects, and still maintains its own mechanical properties in a humid environment. In addition, polyethylene fiber has a low thermal conductivity, which plays a role of heat insulation and fire prevention. It also has good anti-corrosion performance, which can effectively prevent the enviro...

Embodiment 2

[0037] The structure of this embodiment is basically the same as that of the protective flap of the wing fuel tank in Embodiment 1, including the flap body, the flap body and the clamping pressure ring 4 clamping the skin 5, and the flap body includes the protective layer 1 and the protective layer 1 The inner reinforcement layer 2, the protective layer 1 is used for lightning protection and fire prevention, and the reinforcement layer 2 is made of polyethylene fiber, which is used to resist the impact of external objects.

[0038] The difference is that the specific shape of the cover body is not limited, and the specific structure and material of the protective layer 1 are not limited, as long as the cover body can play an excellent role in impact resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com