A multi-layer impact-resistant laminated glass based on cocoon fiber distribution and gradient layered structure and its preparation method

A technology of laminated glass and multi-layer glass, which is applied in the direction of layered products, chemical instruments and methods, glass/slag layered products, etc., and can solve problems such as large safety hazards, poor impact resistance performance, and reduced strength of laminated glass. Achieve the effect of maintaining integrity, improving impact protection performance, and improving impact protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

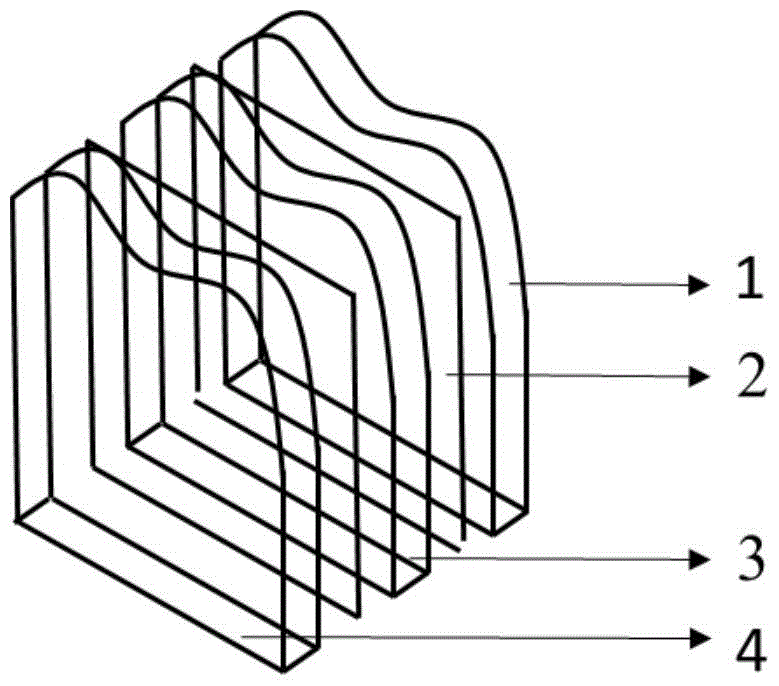

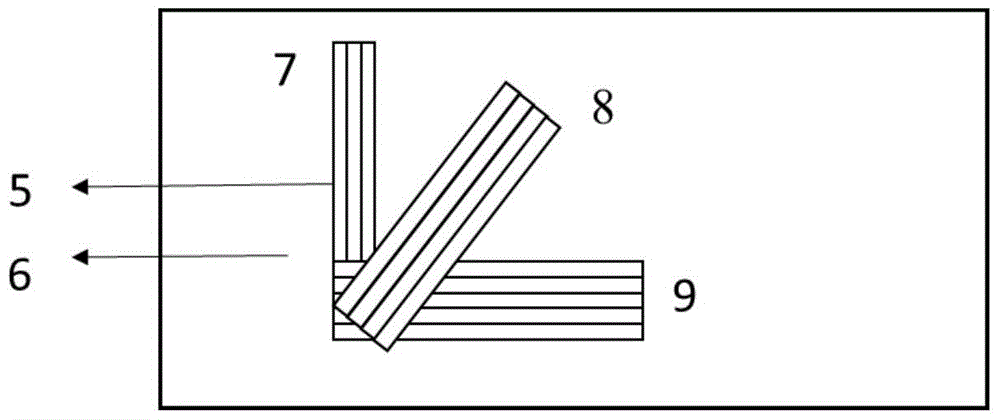

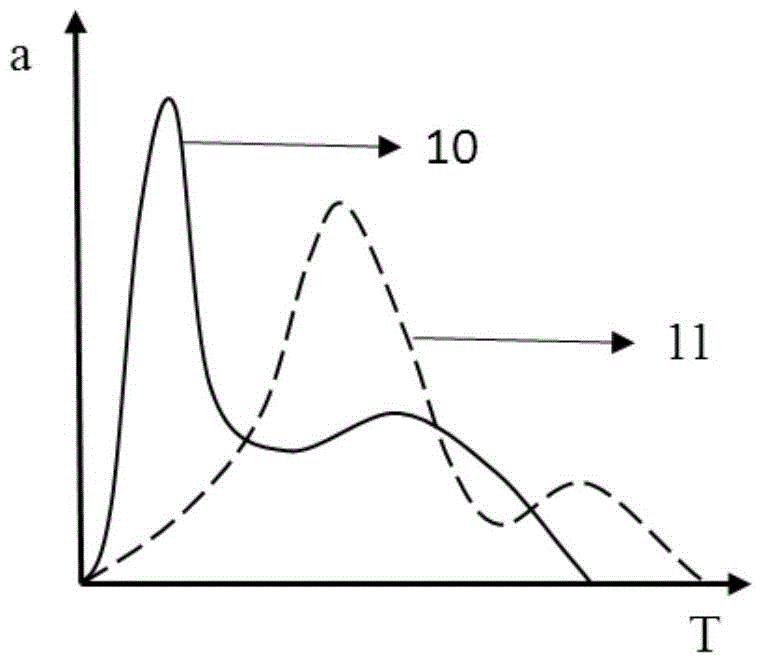

[0032] According to the enlightenment of silkworm cocoon materials and structures in the biological world, the present invention selects 10 layers of glass with different strengths (decreasing from inside to outside), and the distribution direction of each layer of glass fiber is anisotropic, and a suitable PVB material is selected between each layer of glass As the intermediate film, it is preheated and pre-pressed at 120°C-140°C, and at the same time, each side is vacuumed with a vacuum tube to bond the layers of glass together to prevent damage caused by glass fragments after impact.

[0033] Such as figure 1 As shown, the main structure of the multi-layer impact-resistant laminated glass based on the cocoon gradient layered structure, its main components are 10 layers of plexiglass with decreasing strength from inside to outside and PVB interlayer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com