Remote three-dimensional scanning system and method based on machine vision

A three-dimensional scanning and machine vision technology, applied in the field of remote three-dimensional scanning methods and systems, can solve the problems of complex equipment structure, harsh scanning conditions, and difficulty in ensuring binocular parallelism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention provides a kind of three-dimensional scanning system and method, wherein the present invention uses software environment: Win7+Vs2010 etc.; Hardware environment: Intel (R) Core (TM) 2QuadCPUQ84002.66HzCPU, more than 2G internal memory; Development language: C++, C; Library Function: OpenCV computer vision library 2.3 or above.

[0100] First introduce the hardware part of the present invention:

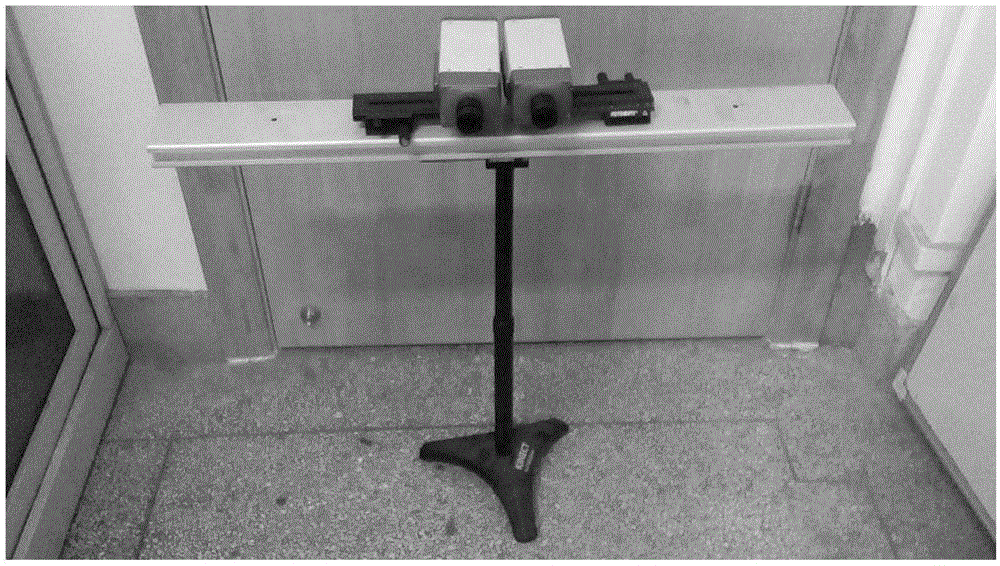

[0101] A remote three-dimensional scanning system based on machine vision, including a camera, a pair of cameras installed on a horizontal bracket, and the optical axes of the two cameras are parallel to each other and parallel to the horizontal plane; the two cameras are connected to the computer system through a switch ; The scanned object is placed in the common field of view in front of the two cameras, and the scanned object is scanned at a uniform speed by a laser; the scanning system also includes a calibration plate and a calibration light source a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com