Self-antibacterial mask material as well as preparation method and application thereof

A facial mask and ability technology, applied in the field of daily chemicals, can solve the problems of low sterilization rate, no broad-spectrum long-term effect, limited antibacterial ability, etc., and achieve the effect of maintaining antibacterial ability, no added preservatives, and increasing storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

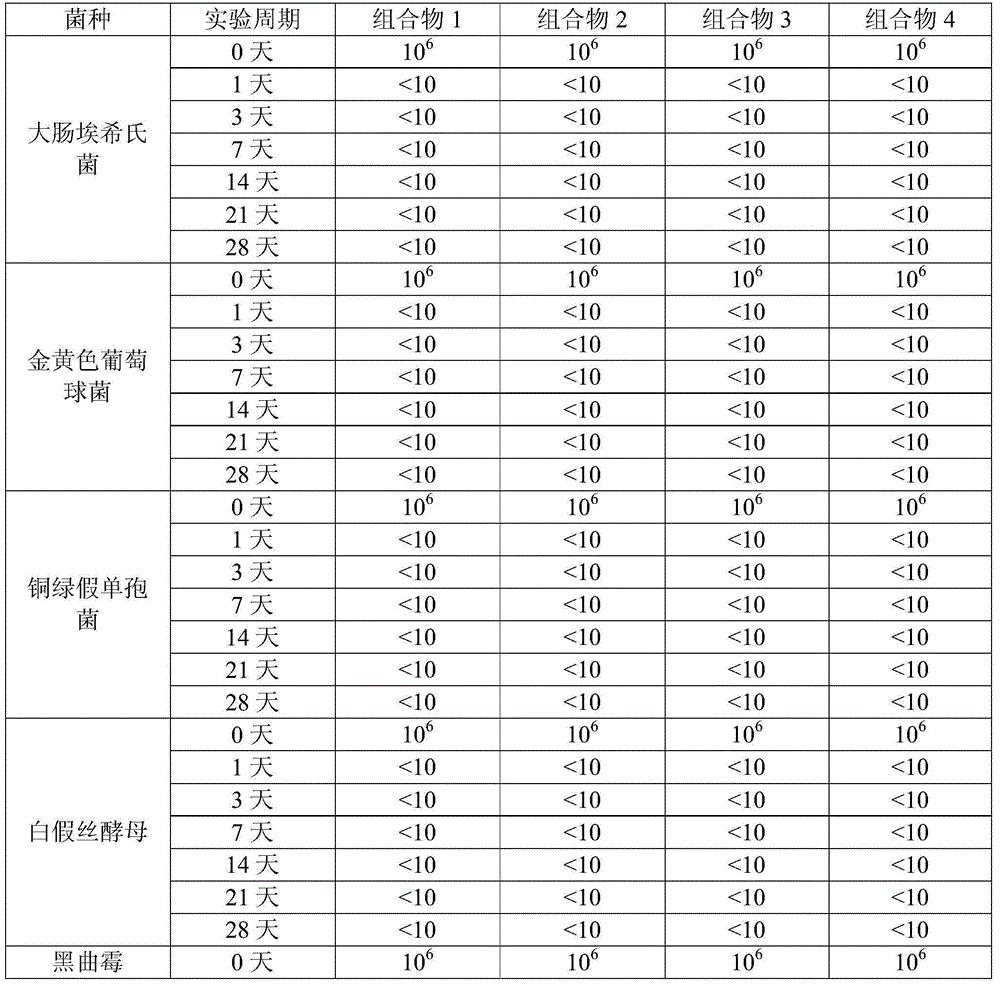

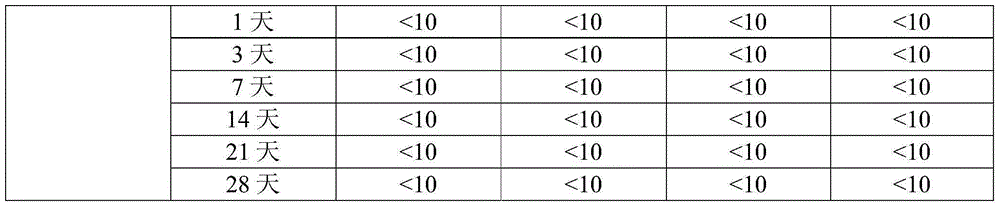

Examples

Embodiment 1

[0047] (1) with 0.1 mass part of Artemisia argyi essential oil (commercially available, food grade or cosmetic grade, the same below), 0.2 mass part of patchouli essential oil (commercially available, food grade or cosmetic grade, hereinafter the same) and 0.7 mass part of fennel essential oil (commercially available, food grade or cosmetic grade, the same below) was added to 2 parts by mass of lauryl phosphate (commercially available, cosmetic grade), homogenized at 3000 rpm for 15 minutes, and set aside.

[0048] (II) 0.5 parts by mass of tremella heteropolysaccharide (commercially available, food grade or cosmetic grade, the same below), 1 mass part of citrus pectin (commercially available, food grade or cosmetic grade, the same below) are added to 50 parts by mass in turn Temperature is 65 ℃ water, 200rpm stirs 10min, Tremella heteropolysaccharide and pectin dissolve completely, cools down to 45 ℃, adds the solution that step (1) obtains, 300rpm stirs 30min, set aside.

[...

Embodiment 2

[0055] (1) Add 0.2 parts by mass of mugwort essential oil, 0.4 parts by mass of patchouli essential oil and 0.4 parts by mass of fennel essential oil into 3 parts by mass of emulsifier (stearyl phosphate), homogenize at 5000 rpm for 30 minutes, and set aside.

[0056] (II) Add 1 mass part of white fungus heteropolysaccharide and 2 mass parts of pectin to 50 parts by mass of water at a temperature of 85° C., stir at 400 rpm for 20 minutes, the white fungus heteropolysaccharide and pectin are completely dissolved, cool to 50° C., add Step (I) solution, stirred at 600rpm for 45min, set aside.

[0057] (III) Dissolve 0.8 parts by mass of polyglutamic acid in 50 parts by mass of water at 25°C, stir at 400rpm for 20min, polyglutamic acid is completely dissolved; heat up to 75°C, stir at 600rpm, and slowly add dropwise to the obtained product in step (II) The solution was added dropwise in 60 minutes. After the dropwise addition, continue to insulate and stir for 45 min.

[0058] (...

Embodiment 3

[0063] (1) Add 0.15 parts by mass of mugwort essential oil, 0.3 parts by mass of patchouli essential oil and 0.55 parts by mass of fennel essential oil into 2.5 parts by mass of emulsifier (C20-22 alcohol phosphate), homogenize at 4500 rpm for 20 minutes, and set aside.

[0064] (II) Add 0.75 parts by mass of Tremella heteropolysaccharide and 1.5 parts by mass of pectin to 50 parts by mass of water at a temperature of 70° C., stir at 300 rpm for 15 minutes, and the Tremella heteropolysaccharide and pectin are completely dissolved. Cool down to 48° C., add Step (I) solution, stirred at 450rpm for 40min, set aside.

[0065] (III) Dissolve 0.5 parts by mass of polyaspartic acid in 50 parts by mass of water at 23°C, stir at 300rpm for 15min, polyaspartic acid is completely dissolved; heat up to 70°C, stir at 450rpm, slowly drop into step (II) The obtained solution was added dropwise within 50 minutes. After the dropwise addition, continue to insulate and stir for 40 min.

[0066...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com