A combustible gas recycling heat treatment furnace

A technology for heat treatment furnace and gas import, which is used in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve problems such as affecting the normal operation of the carbonized gas outlet pipe, low energy recovery rate, and potential safety hazards, and achieve energy recovery. The effect of utilization, high heat utilization rate and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

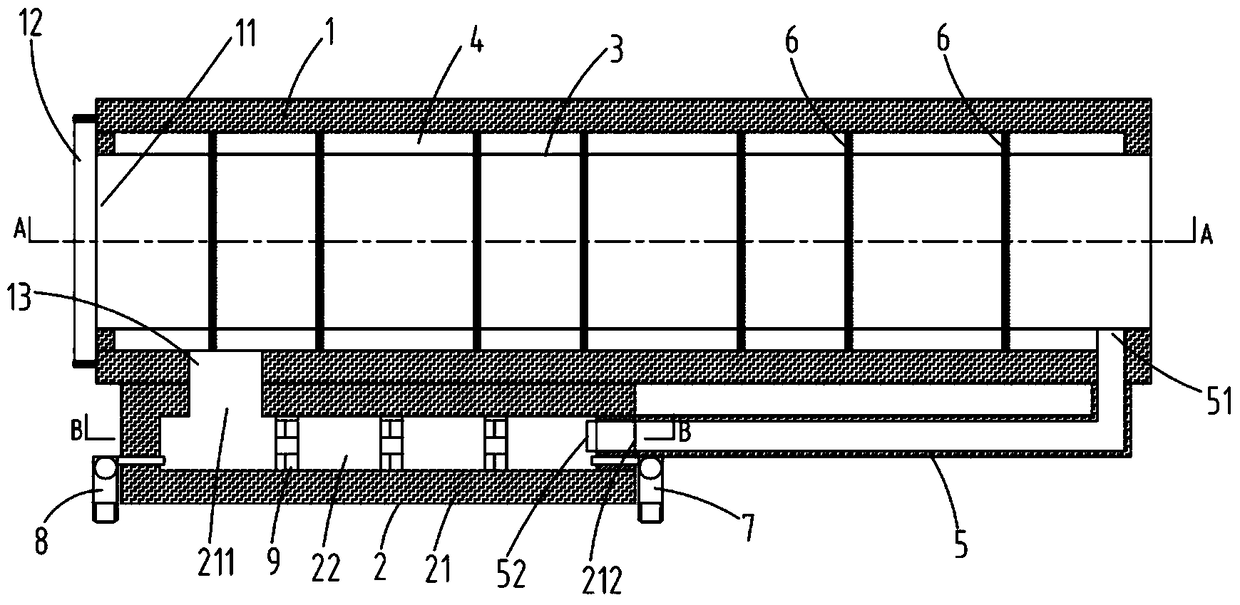

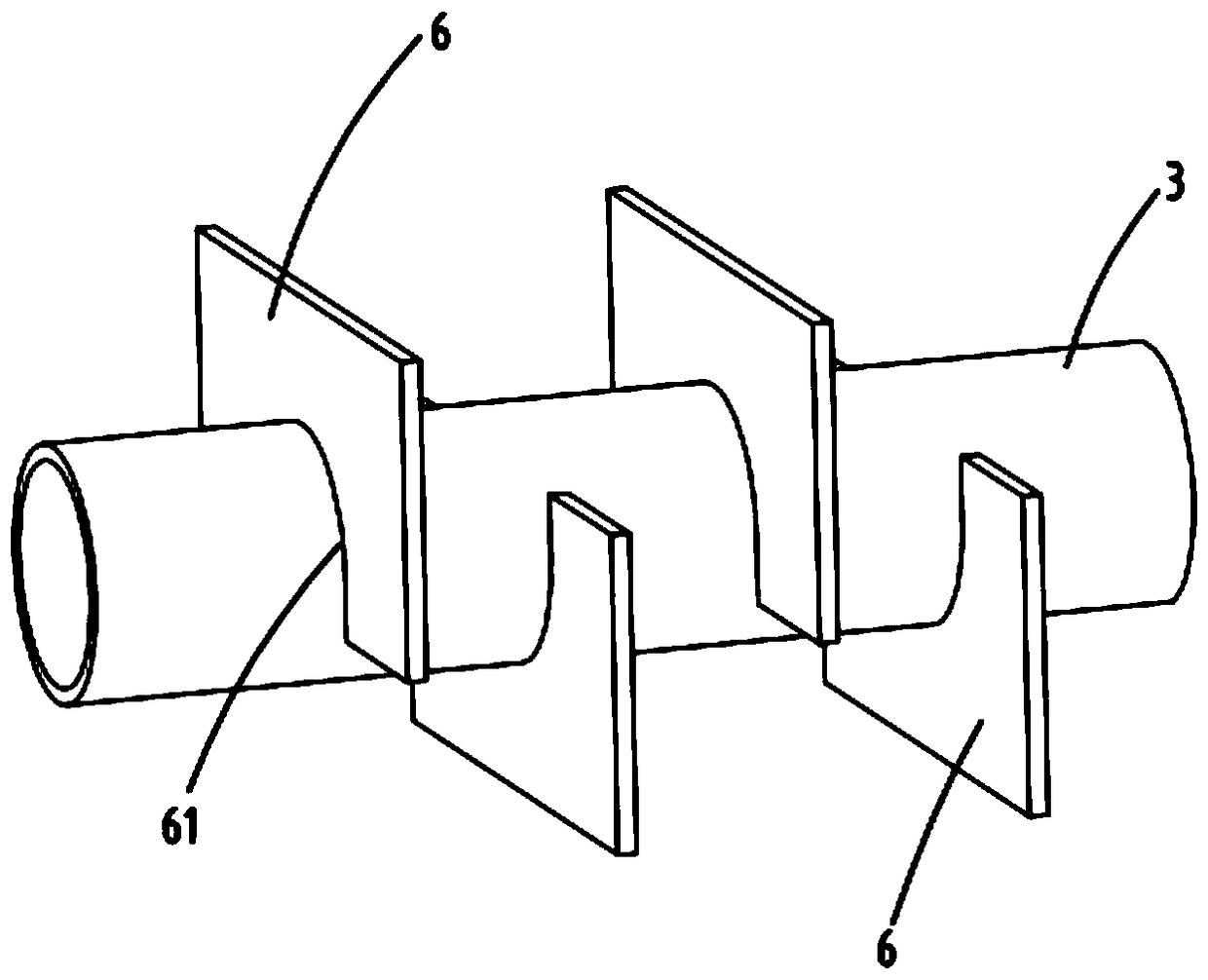

[0031] Such as figure 1 As shown, the present invention provides a combustible gas recycling heat treatment furnace, including a furnace body 1, a combustion chamber 2 equipped with a burner, and a waste gas discharge pipe 5, and a furnace chamber 3 for heat treatment of materials is provided in the furnace body 1, as shown in FIG. figure 2 As shown, the feed end 11 of the furnace body 1 is provided with a furnace door 12 that can be opened or closed, wherein the furnace body 1 is square, and the furnace furnace 3 is cylindrical. In the closed annular hot gas duct 4 , a high-temperature flue gas inlet 13 and a flue gas outlet 14 communicating with the hot gas duct 4 are provided on the furnace body 1 . The combustion chamber 2 includes a housing 21 with a combustion chamber 22 inside. The housing 21 can be designed as a cuboid, cube or other shapes as a whole. The housing 21 is provided with a gas injection port 211 and a gas inlet communicating with the combustion chamber 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com