Coastal saline area conditioner and preparation method and application method thereof

An application method and saline-alkali land technology, applied in the direction of chemical instruments and methods, applications, fertilization devices, etc., can solve the problems of low soil pH adjustment ability and high cost of conditioner, and achieve enhanced adsorption, improved physical and chemical properties, good water retention and inhibition The effect of returning salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

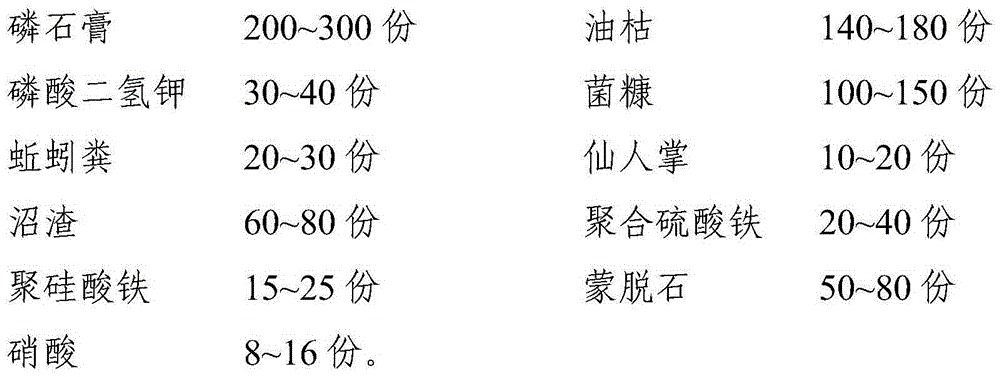

[0033] raw material:

[0034] Phosphogypsum 200kg, oil 140kg, potassium dihydrogen phosphate 30kg, fungus chaff 100kg, vermicompost 20kg, cactus 10kg, biogas residue 60kg, polyferric sulfate 20kg, polysilicate iron 15kg, montmorillonite 50kg and nitric acid 8kg.

[0035] Preparation:

[0036] (1) Raw material pretreatment: Dry the phosphogypsum to a moisture content of 5%, then crush it into a 60-mesh fine powder to obtain phosphogypsum powder; cut the 2-year-old cactus fleshy stem into length and width of 1cm and a thickness of 0.5cm The thin slices are then dried at a temperature of 500°C until the moisture content is 3% to obtain cactus slices;

[0037] (2) Montmorillonite modification: use a ball mill to grind the montmorillonite into a fine powder with a fineness of ≤0.05mm, then send it into an ultrasonic device, treat it at an ultrasonic power of 600w for 20min, and then send it into a calcination tower at 300°C Calcined at high temperature for 2 hours, cooled and sen...

Embodiment 2

[0044] raw material:

[0045] Phosphogypsum 300kg, oil 180kg, potassium dihydrogen phosphate 40kg, fungus chaff 150kg, vermicompost 30kg, cactus 20kg, biogas residue 80kg, polyferric sulfate 40kg, polysilicate iron 25kg, montmorillonite 80kg and nitric acid 16kg.

[0046] Preparation:

[0047] (1) Raw material pretreatment: Dry the phosphogypsum to a moisture content of 7%, then crush it into a fine powder of 60 to 200 meshes to obtain phosphogypsum powder; cut the 10-year-old cactus fleshy stem into 3cm in length and 3cm in width and 3cm in thickness 2cm slices, then dried at a temperature of 600°C until the moisture content is 5%, to obtain cactus slices;

[0048] (2) Montmorillonite modification: use a ball mill to grind the montmorillonite into a fine powder with a fineness of ≤0.05mm, then send it into an ultrasonic device, treat it for 40min at an ultrasonic power of 1000w, and then send it into a calcination tower with a temperature of 600°C. Calcined at a high temper...

Embodiment 3

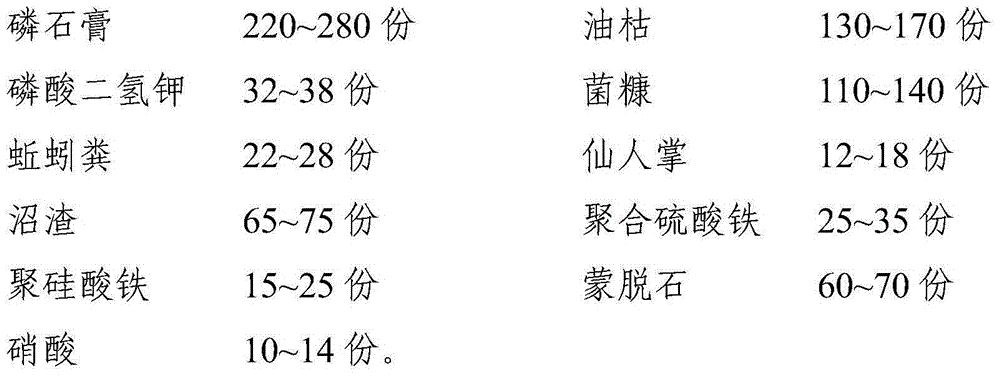

[0055] raw material:

[0056] Phosphogypsum 250kg, oil 160kg, potassium dihydrogen phosphate 35kg, fungus chaff 130kg, vermicompost 25kg, cactus 15kg, biogas residue 70kg, polyferric sulfate 30kg, polysilicate iron 20kg, montmorillonite 65kg and nitric acid 12kg.

[0057] Preparation:

[0058] (1) Raw material pretreatment: dry the phosphogypsum to a moisture content of 6%, then crush it into 80-mesh fine powder to obtain phosphogypsum powder; cut the 5-year-old cactus fleshy stem into 2cm in length and 1cm in width Thin slices, then dried at a temperature of 400°C until the moisture content is 4%, to obtain cactus slices;

[0059] (2) Montmorillonite modification: use a ball mill to grind the montmorillonite into a fine powder with a fineness of ≤0.05mm, then send it into an ultrasonic device, process it for 30min at an ultrasonic power of 800w, and then send it into a calcination tower with a temperature of 500°C. Calcined at a high temperature for 3 hours, cooled and sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com