Repairing structure with composite repairing piece and method for forming repairing structure

A composite material and patch technology, which is applied in the field of patch repair structure, can solve problems such as environmental sensitivity, low reliability, and high weight gain, and achieve the effects of improving bonding, reducing use risks, and small structural weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

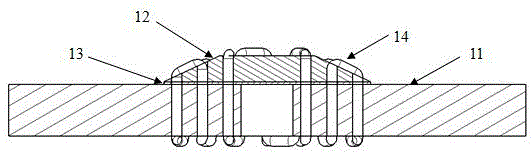

[0039] The pre-cured sheet and the proposed method are used to repair the cracking damage of the epoxy-based carbon fiber reinforced composite structure with a thickness of 4 mm. The steps are as follows:

[0040] (1) Determining the damage area and extent of the composite structure as a cracking damage with a length of 4 mm;

[0041] (2) First remove the adhesive and sealant on the residual repair area, then apply the drilling method to remove the material within the circumscribed circle of the cracking damage, and finally clean the repair area with a vacuum cleaner, then use 180 and 360 grit sandpaper respectively to polish and repair. area, clean the repair area with solvent, and use a heat gun for local heating and drying;

[0042] (3) Prepare composite material pre-cured patch (16 mm in diameter, 2 mm in thickness, tip ratio of 2:1), TESA8432 hot melt adhesive film (diameter of 16mm, 0.2mm thickness) and carbon fiber suture (500mm length, 0.7mm diameter) impregnated with...

Embodiment 2

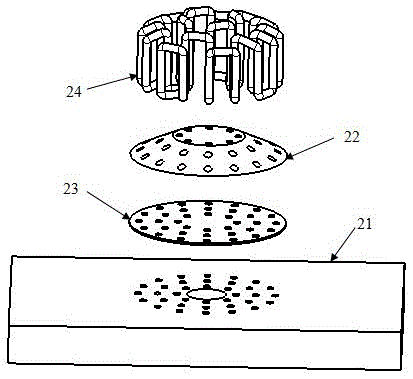

[0050] Using the prepreg and the proposed method, the internal delamination damage of the epoxy-based carbon fiber reinforced composite structure with a thickness of 6 mm was excavated and repaired, and the steps were as follows:

[0051] (1) It is determined that there is delamination damage at a depth of 3 mm inside the composite structure, and the circumcircle of delamination damage is 8 mm;

[0052] (2) Use a portable pneumatic die milling to cut off the material in the damaged area. The depth of the cut area is 3 mm, the diameter of the bottom is 8 mm, and the slope of the edge is 3:1, then sandpaper is used to obtain a smooth slope, and finally a vacuum cleaner is used. After cleaning the repair area, polish the repair area with 180-grit and 360-grit sandpaper respectively, clean the repair area with solvent, and use a hot air gun for local heating and drying;

[0053] (3) Prepare composite prepregs of different sizes (the smallest prepreg diameter is 8 mm, the largest d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com