A kind of preparation method of rice platinum

A technology of rice platinum and crude products, which is applied in the field of platinum anti-tumor drugs, can solve the problems of low recrystallization yield and low solubility, and achieve the effects of high purity, low production cost and high quality preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

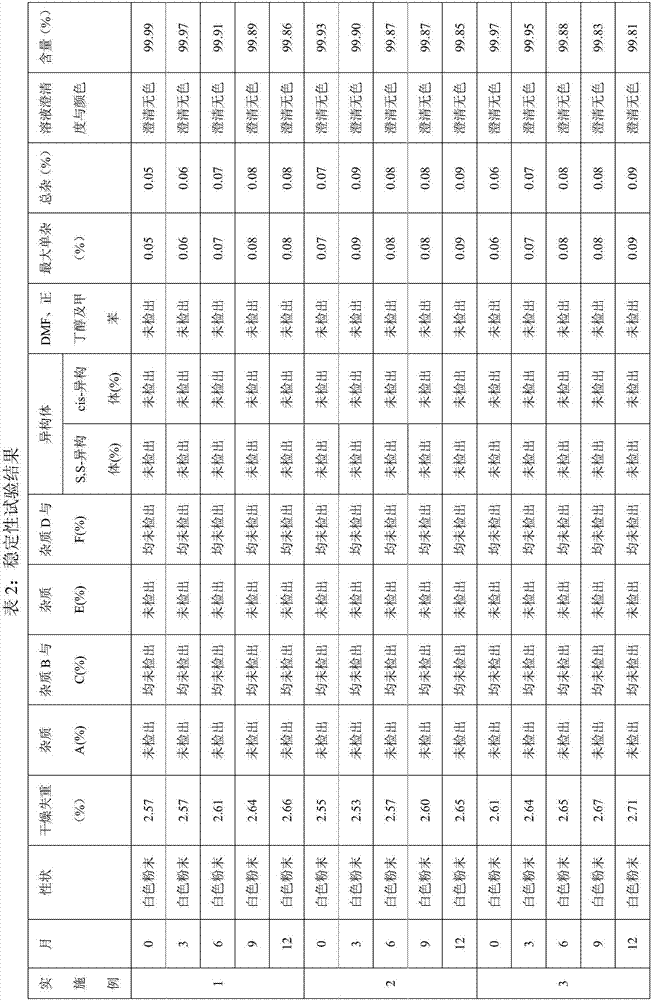

[0042] Example 1: Refinement of Miplatin

[0043] The crude Miplatin used in this example was prepared by the preparation method of Japanese Patent JP11-315088, with a purity of 97.18% (detected by HPLC), a maximum of 1.86% of single impurities, and a total of 3.71% of impurities.

[0044] Refining process:

[0045] 1) Prepare 60 ml of a mixed solution of dimethylformamide and n-butanol (DMF: n-butanol = 2:1), heat up to 145°C, add 5.00 g of Miplatin crude product, keep stirring until completely dissolved, and obtain a Miplatin crude product solution ;

[0046] 2) After the solution is clarified, add activated carbon 0.10g, continue to keep stirring for 30 minutes at a speed of 25 rev / min, filter, and collect the filtrate;

[0047] 3) The filtrate was cooled to 80°C in 1.5 hours, 20ml of toluene was added dropwise in 30 minutes, and then the temperature was kept stirring for 1 hour at a speed of 15 rev / min;

[0048] 4) After the reaction finishes, cool down to 25 ℃ again, s...

Embodiment 2

[0050] Example 2: Refinement of Miplatin

[0051] The crude product of Miplatin used in this example was prepared by the preparation method disclosed in the international patent WO 94 / 14470, with a purity of 95.89% (detected by HPLC), a maximum single impurity of 1.71%, and a total impurity of 3.35%.

[0052] Refining process:

[0053] 1) Prepare 60 ml of a mixed solution of dimethylformamide and n-butanol (DMF: n-butanol = 3:1), heat up to 140 ° C, add 5.00 g of Miplatin crude product, keep stirring until completely dissolved, and obtain a crude Miplatin solution ;

[0054] 2) After the solution is clarified, add activated carbon 0.05g, continue to keep stirring for 40 minutes at a speed of 20 rev / min, filter, and collect the filtrate;

[0055] 3) The filtrate was cooled to 90° C. in 1 hour, and 15ml of toluene was added dropwise in 20 minutes, and then stirred at 10 rev / min for 2 hours;

[0056] 4) After the reaction, the temperature was lowered to 30° C. again, crystals ...

Embodiment 3

[0058] Example 3: Refinement of Miplatin

[0059] The crude Miplatin used in this example was prepared by the preparation method disclosed in European Patent 0193936A1, with a purity of 96.76% (detected by HPLC), a maximum single impurity of 1.58%, and a total impurity of 2.96%.

[0060] Refining process:

[0061] 1) Prepare 50 ml of a mixed solution of dimethylformamide and n-butanol (DMF: n-butanol = 1:1), heat up to 150 ° C, add 5.00 g of Miplatin crude product, keep stirring until completely dissolved, and obtain a crude Miplatin solution ;

[0062] 2) After the solution is clarified, add activated carbon 0.15g, continue to keep stirring for 20 minutes at a speed of 30 rev / min, filter, and collect the filtrate;

[0063] 3) The filtrate was cooled to 70°C within 2 hours, and 25ml of toluene was added dropwise within 40 minutes, and then stirred at 20 rev / min for 0.5 hours;

[0064] 4) After the reaction finishes, cool down to 20 ℃ again, separate out crystals, and grow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com