Technique for simple substance salt separation with co-production of sodium sulfide from high-salinity wastewater

A technology of high-salt wastewater and process method, which is applied in alkali metal sulfide/polysulfide, alkali metal sulfite/sulfate purification, alkali metal halide purification, etc. Profits, the realization of resource utilization, the effect of simple and stable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

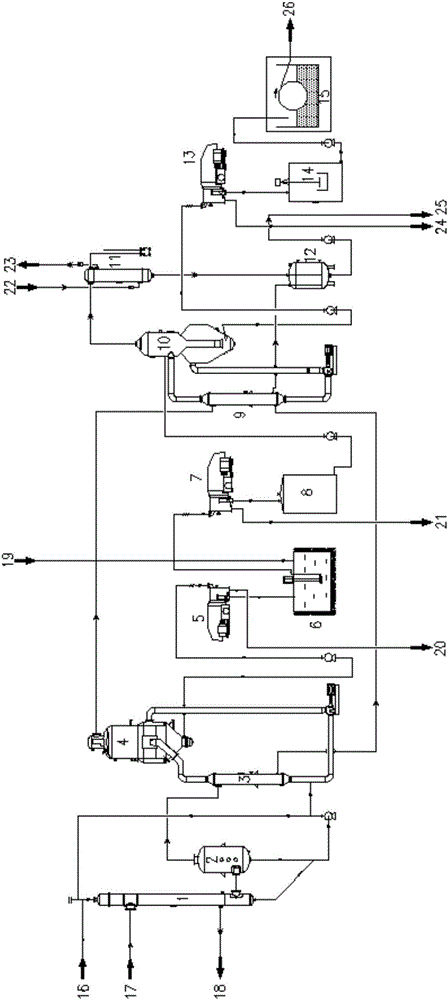

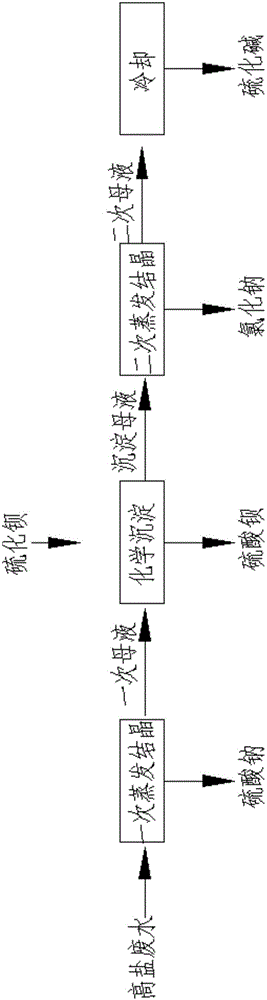

[0065] This embodiment is a process for separating the elemental salts of high-salt wastewater containing sodium sulfate and sodium chloride and co-producing soda sulfide. The process flow is as follows figure 2 shown.

[0066] In this embodiment, the primary evaporation and crystallization adopts a double-effect downstream process, and the first-effect evaporator adopts a falling film evaporator, including a first-effect evaporator and a second-effect evaporation crystallizer; the first-effect evaporator includes a first-effect separation chamber 2 and a first-effect evaporator. The heating chamber 1; the second-effect evaporation crystallizer adopts a forced circulation evaporation crystallizer, and the second-effect evaporation crystallizer includes a second-effect crystallization separator 4 and a second-effect heating chamber 3 . Sedimentation tank 6 is used for chemical precipitation. The secondary evaporation crystallizer adopts a single-effect forced circulation evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com