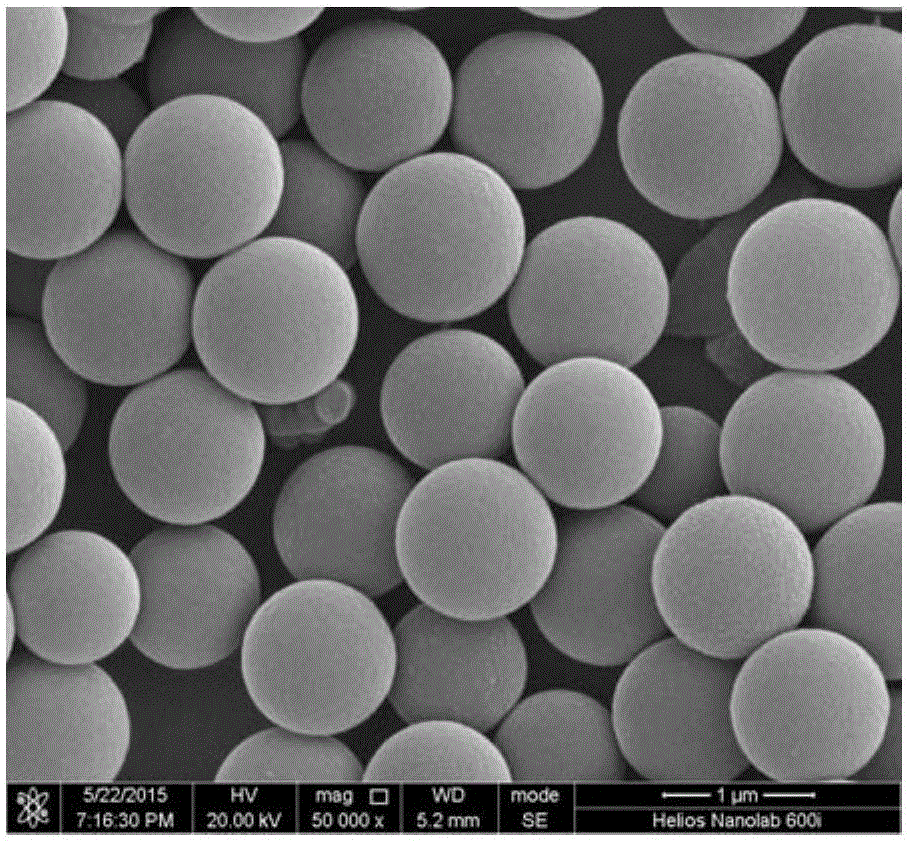

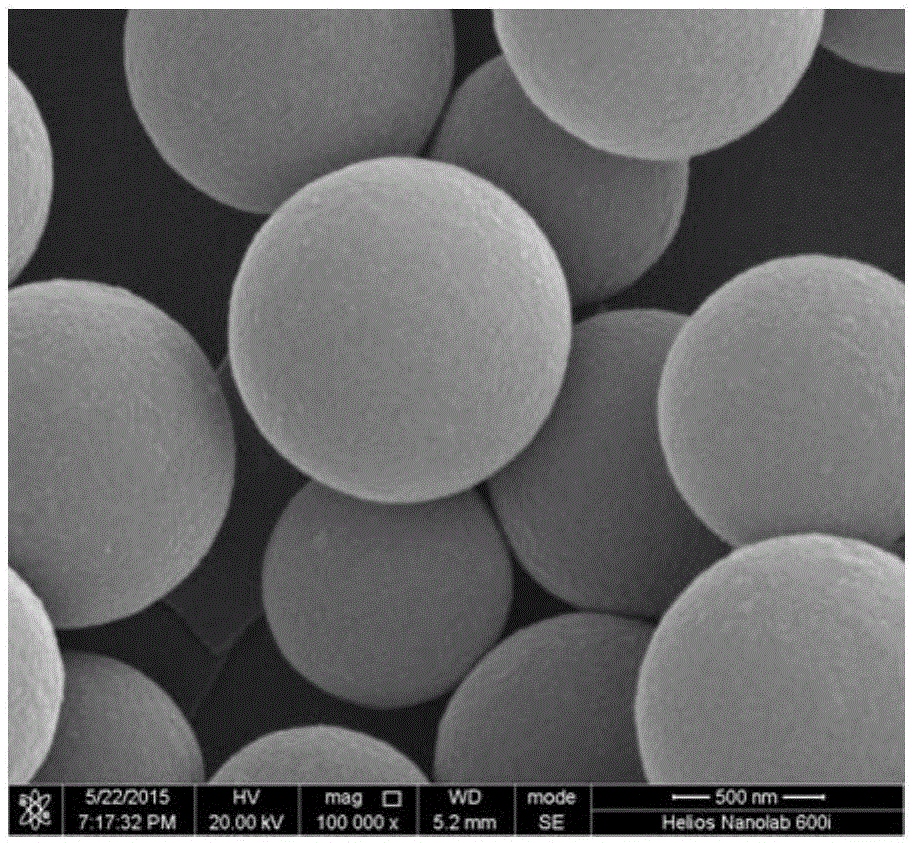

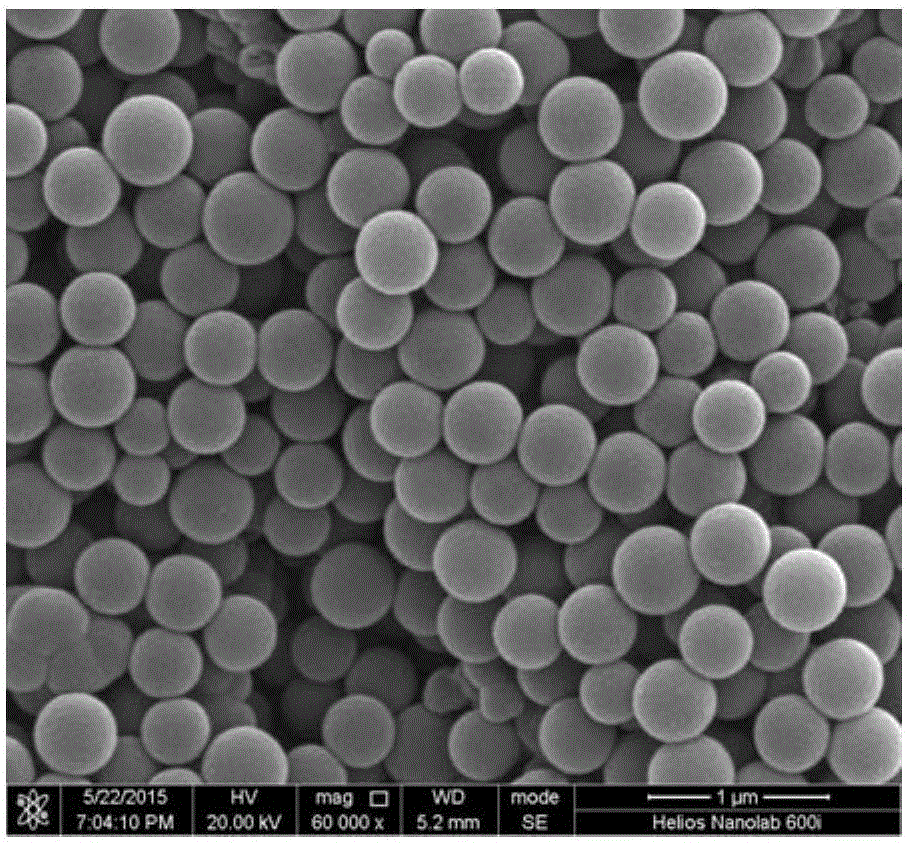

Preparation method of nitrogen-doped carbon microspheres

A nitrogen-doped carbon and microsphere technology is applied in the field of preparation of carbon-doped microspheres, which can solve the problems of harsh reaction conditions and high equipment requirements, and achieve the effects of high selectivity, uniform distribution, and simplified preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Specific embodiment one: the preparation method of a kind of nitrogen-doped carbon microsphere of this embodiment is carried out according to the following steps:

[0033] 1. According to o-toluidine, H 2 o 2 and FeCl 3 The molar ratio is 6: (12 ~ 16): (0.8 ~ 1) ratio to weigh o-toluidine, H 2 o 2 and FeCl 3 , the H 2 o 2 and FeCl 3 Prepare solutions respectively, add o-toluidine to H under stirring condition 3 PO 4 In the aqueous solution, stir evenly, then add H 2 o 2 Aqueous solution and FeCl 3 aqueous solution, and then stirred at room temperature for 10 to 15 minutes to obtain a precursor solution;

[0034] 2. Transfer the original precursor solution obtained in step 1 to the reactor, seal it well, put the reactor into an oven, keep it at 130-160°C for 5-8 hours, cool to room temperature, centrifuge, and pour off the upper layer to clear the night , after washing the lower precipitate with distilled water and ethanol, put it in a vacuum drying oven at ...

specific Embodiment approach 2

[0036] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is that H in step two 3 PO 4 H in aqueous solution 3 PO 4 The concentration is 0.4~0.5mol / L; Others are the same as the first embodiment.

specific Embodiment approach 3

[0037]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, H 2 o 2 Aqueous solution is by H 2 o 2 It is mixed with water at a volume ratio of 30:100. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mass specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com