Nitrogen-doped carbon aerogel and preparation method thereof

A carbon aerogel and nitrogen doping technology, which is applied in the field of preparation of nitrogen-doped carbon aerogel, can solve the problems of wide explosion range, dangerous operation process, difficult control of doping amount, etc., and achieves easy control and wide application. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

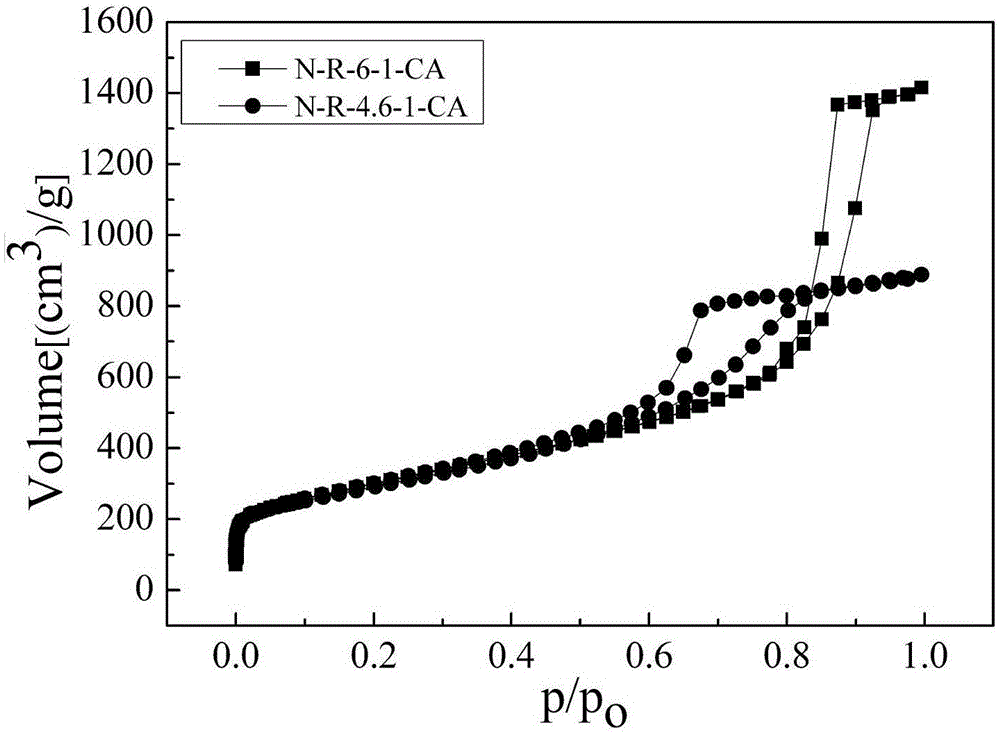

[0028] Step 1. At 40°C, prepare a trihydroxypyridine solution with a concentration of 30g / L, then add resorcinol, and after the solution is clarified, add a formaldehyde solution with a volume concentration of 38%, stir for 20min, and then add a solution with a mass concentration of 40% % potassium carbonate solution, stirred for 10min to obtain a reaction solution; the mol ratio of the trihydroxypyridine to resorcinol was 1:4.6; the mol ratio of the resorcinol to formaldehyde was 1:1.5; the resorcinol The mol ratio of hydroquinone and potassium carbonate is 1:100;

[0029] Step 2. Put the reaction solution into a high-voltage pulse treatment chamber and pretreat it with a high-voltage pulse electric field for 60 minutes, then stir it at a speed of 50 r / min for 1 hour, and then place it in a container at 40 ° C for 3 days to obtain an airgel; The glue is added into acetone and left to stand for solution exchange, and the acetone is replaced every day until the moisture content...

Embodiment 2

[0034]Step 1. At 60°C, prepare a trihydroxypyridine solution with a concentration of 90 g / L, then add resorcinol, and after the solution is clarified, add a formaldehyde solution with a volume concentration of 38%, stir for 50 minutes, and then add a solution with a mass concentration of 60 % potassium carbonate solution, stirred for 30min to obtain a reaction solution; the mol ratio of the trihydroxypyridine to resorcinol was 1:6; the mol ratio of the resorcinol to formaldehyde was 1:2.5; the resorcinol The mol ratio of hydroquinone and potassium carbonate is 1:500;

[0035] Step 2. Put the reaction solution into a high-voltage pulse treatment chamber and pretreat it with a high-voltage pulse electric field for 90 minutes, then stir it at a speed of 100 r / min for 3 hours, and then place it in a container at 60 ° C for 3 days to obtain an airgel; The glue is added into acetone and left to stand for solution exchange, and the acetone is replaced every day until the moisture con...

Embodiment 3

[0040] Step 1. At 50°C, prepare a trihydroxypyridine solution with a concentration of 60g / L, then add resorcinol, and after the solution is clarified, add an acetaldehyde solution with a volume concentration of 38%, stir for 30min, and then add a solution with a mass concentration of 50% potassium carbonate solution was stirred for 20min to obtain a reaction solution; the mol ratio of the trihydroxypyridine to resorcinol was 1:5; the mol ratio of the resorcinol to acetaldehyde was 1:1.5; The mol ratio of said resorcinol and salt of wormwood is 1:300;

[0041] Step 2. Put the reaction solution into a high-voltage pulse treatment chamber and pretreat it with a high-voltage pulse electric field for 80 minutes, then stir it at a speed of 80 r / min for 2 hours, and then place it in a container at 50 ° C for 5 days to obtain an airgel; The glue is added into acetone and left to stand for solution exchange, and the acetone is replaced every day until the moisture content in the exchan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com