Non-noble metal oxygen evolution catalyst CuNiS2 with controllable shape

A catalyst and oxygen evolution technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low catalytic efficiency and high catalyst cost, and achieve low resistance and good oxygen evolution catalytic performance , the effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The water used in the experiment was ultrapure water with a conductivity of 18.25MΩ, and the reagents used in the experiment were all analytically pure.

[0026] Instruments and reagents used:

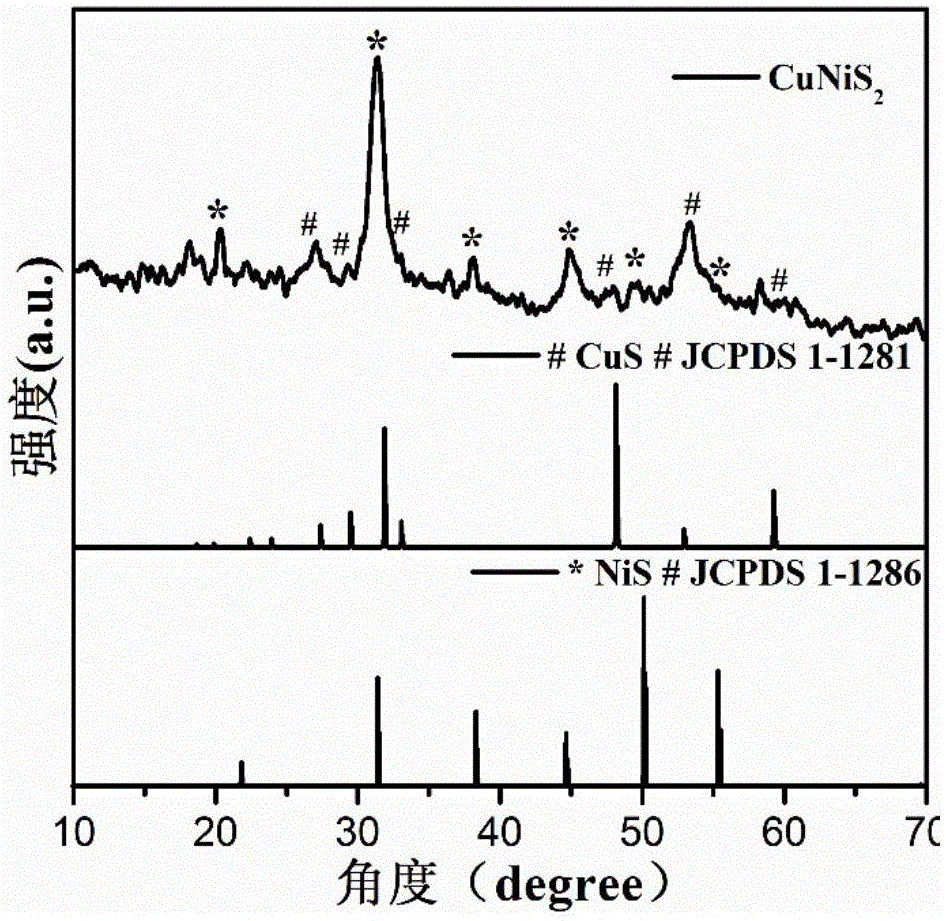

[0027] CHI660E electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd.) was used for cyclic voltammetry experiments; the ultrapure water device (Chengdu Ultrapure Technology Co., Ltd.) of Youput Laboratory was used to prepare ultrapure water; the electronic balance (Shanghai Bole Electromechanical Co., Ltd.) Equipment Co., Ltd.) for weighing drugs; D / max-2400 (Japan Rigaku, Rigaku) for X-ray diffraction characterization; JSM-6701F cold field emission scanning electron microscope (Japan Electronics Co., Ltd.) for morphology characterization of hydrogen evolution catalysis ; micro laser Raman spectrometer (Jobin-Yvon, France) is used for the characterization of hydrogen evolution catalyst; vacuum drying oven (Shanghai Yiheng Scientific Instrument Co., Ltd.); KQ5200 ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com