Production technology for preparing fluorine-containing surfactant free from perfluoro caprylic acid

A surfactant, perfluorooctanoic acid technology, applied in the directions of dissolution, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of magnification, chemical characteristics that cannot be characterized by any molecular chain or group in its structural formula, and various differences. and other problems, to achieve the effect of reducing surface tension, good surface activity characteristics, and good surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment proposes a kind of production process of preparing the fluorosurfactant not containing perfluorooctanoic acid, comprising the following steps:

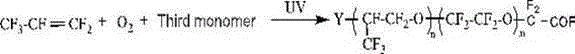

[0060] A: At a temperature of -20°C, send perfluoroalkene, oxygen and a third monomer into the photooxidation reactor, and produce acyl fluoride-containing end group products after photooxidation;

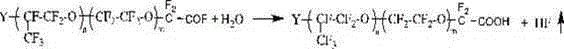

[0061] B: Send the product containing acyl fluoride terminal group into the hydrolysis reaction kettle, and obtain a fluorine-containing low polymer with a carboxylic acid group at one end after hydrolysis;

[0062] C: Send the fluorine-containing low polymer prepared in step B into a heat treatment reactor, and obtain a fluorine-containing oily polymer with a peroxy group of less than 1g / 100g and a carboxylic acid and its salt at one end after the peroxygen removal treatment;

[0063] D: Send the fluorine-containing oily polymer obtained in step C into a neutralization reactor, obtain a finished fluorine-containing ...

Embodiment 2

[0073] The production process for preparing the fluorosurfactant not containing perfluorooctanoic acid involved in this embodiment comprises the following steps:

[0074] A: At a temperature of -25°C, send perfluoroalkene, oxygen and a third monomer into the photooxidation reactor, and produce acyl fluoride-containing end group products after photooxidation;

[0075] B: Send the product containing acyl fluoride terminal group into the hydrolysis reaction kettle, and obtain a fluorine-containing low polymer with a carboxylic acid group at one end after hydrolysis;

[0076] C: Send the fluorine-containing low polymer prepared in step B into a heat treatment reactor, and obtain a fluorine-containing oily polymer with a peroxy group of less than 1g / 100g and a carboxylic acid and its salt at one end after the peroxygen removal treatment;

[0077] D: Send the fluorine-containing oily polymer obtained in step C into a neutralization reactor, obtain a finished fluorine-containing surf...

Embodiment 3

[0087] The difference between this example and Example 1 is that in step A involved in this example, the mass ratio of perfluoroolefin to the third monomer is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com