Method and system for manufacturing radiator elements for heating and radiator element for heating

A technology of radiators and components, applied in the field of manufacturing radiator components and systems for heating and radiator components for heating, can solve problems such as not completely satisfactory methods, and achieve increased heat output and increased heat exchange Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

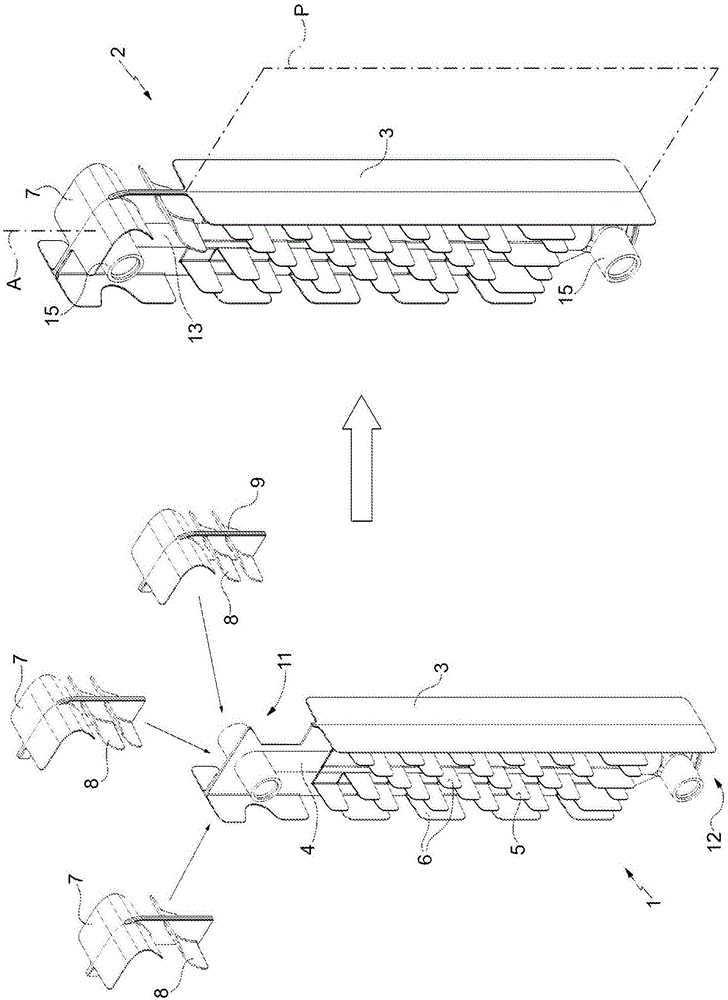

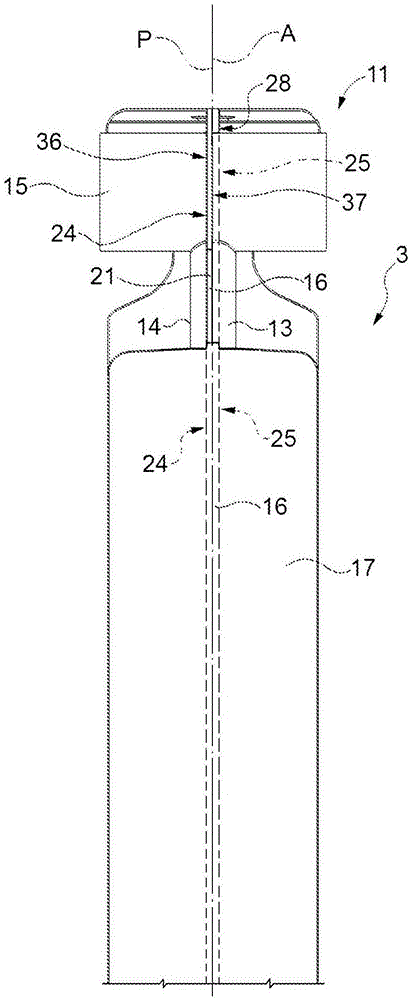

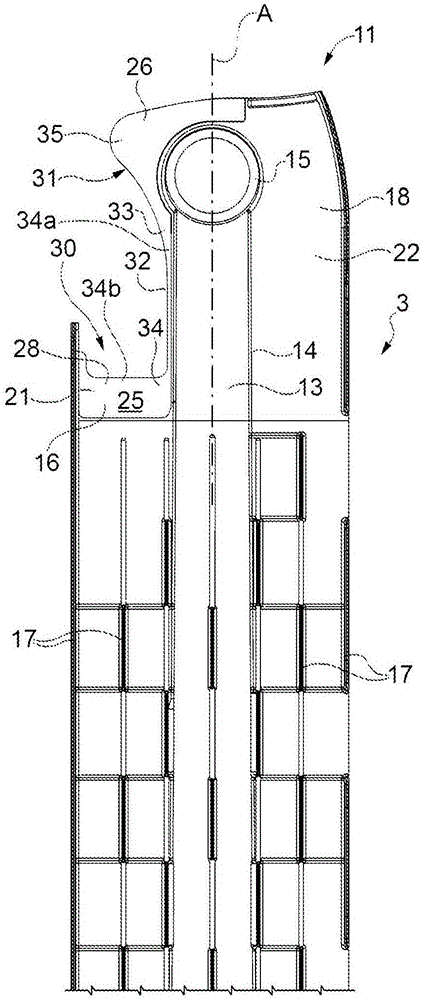

[0023] figure 1 The system 1 for manufacturing a heat sink element 2 in various styles or forms is shown diagrammatically.

[0024] The system 1 comprises at least a base body 3 with an internal chamber for water circulation and a finpack formed by a plurality of heat exchange fins 6 connected to the chamber 4 and / or to each other and a set of heads 7. ) 5, a set of heads 7 is fitted on the base body 3 and has a respective set of fins 8 formed by other heat exchanging fins 9 .

[0025] The heads 7 differ from each other and, in particular, differ from each other in the shape of the respective fin set 8 , ie the shape and / or size of the fins 9 forming the fin set 8 of each head 7 .

[0026] Advantageously, the system 1 comprises a series of substrates 3 that differ from each other, for example in differences between centers and / or other dimensions, and / or in the shape of the fin pack 5 (i.e. in the shape of the fins 6 forming the fin pack 5 shape and / or arrangement) etc. are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com